Feed and feeding method for milk buffalo

A technology of milk buffalo and concentrated feed, applied in the field of breeding, to achieve the effect of improving feed conversion rate, reducing feeding cost, and increasing polyunsaturated fatty acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

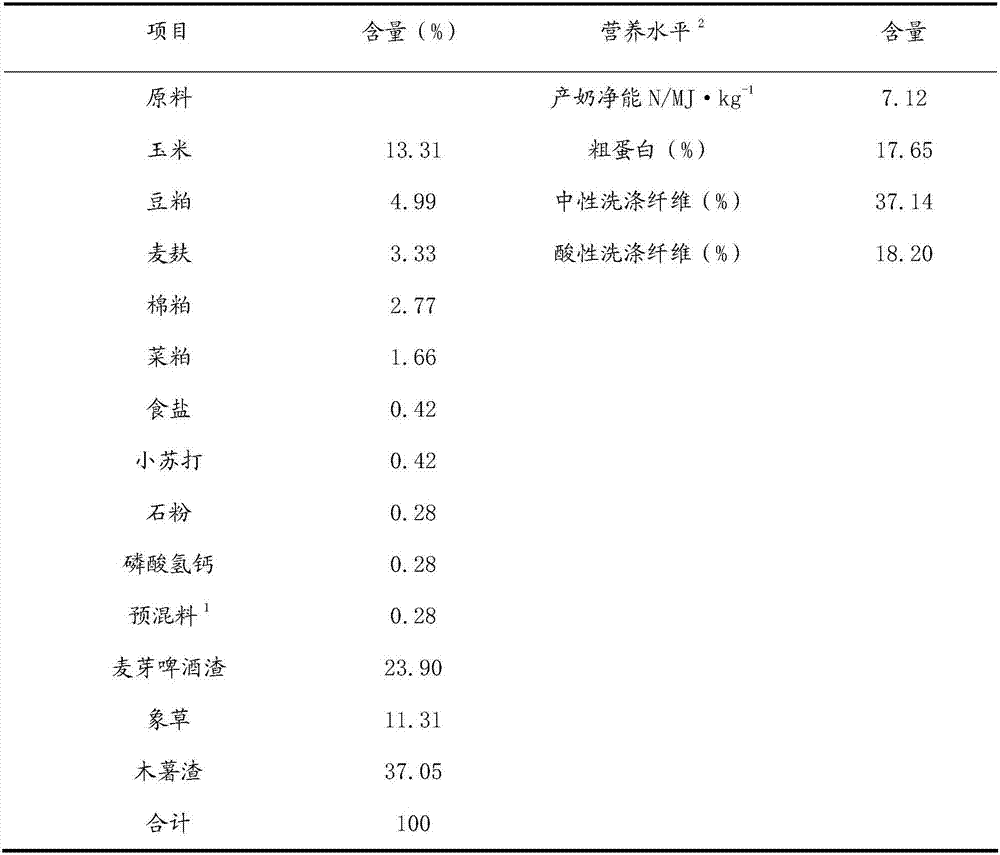

[0023] Embodiment 1: Feed of the present invention

[0024] Add 100g / d and 200g / d hemp oil respectively to the concentrated material of the basic diet of the present invention, and mix with coarse material to obtain the feed described in the present invention.

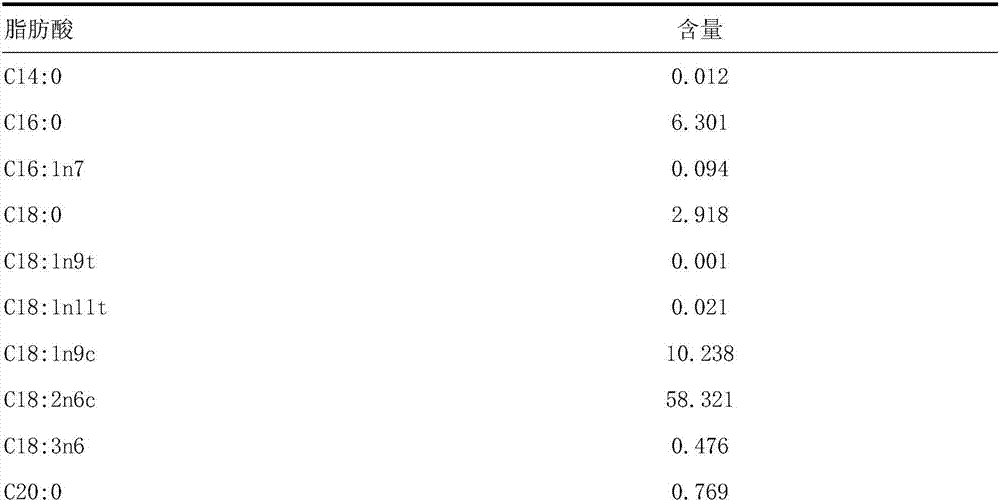

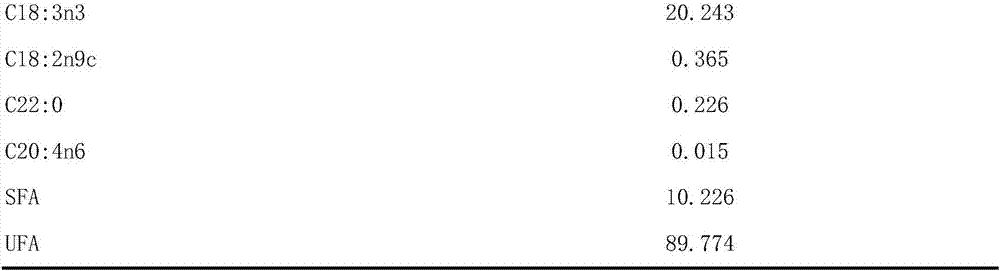

[0025] The hemp oil used in the present invention is made by pressing the hemp seeds purchased from Bama, Guangxi, and the obtained hemp oil fatty acid contains the following components in mass percentage: 10.226% of saturated fatty acid and 89.774% of unsaturated fatty acid.

[0026] The hemp oil fatty acid contains the following mass percentage components: fatty acid C14:0 0.012%, fatty acid C16:0 6.301%, fatty acid C16:1n7 0.094%, fatty acid C18:0 2.918%, fatty acid C18:1n9t0.001%, fatty acid C18 :1n11t 0.021%, fatty acid C18:1n9c 10.238%, fatty acid C18:2n6c 58.321%, fatty acid C18:3n6 0.476%, fatty acid C20:0 0.769%, fatty acid C18:3n3 20.243%, fatty acid C18:2n9c 0.365%, fatty acid C22 :0 0.226%, fatty acid C20:...

Embodiment 2

[0031] Embodiment 2 adopts feed described in the present invention to carry out comparative feeding experiment to milk buffalo

[0032] 1. Test process

[0033] 1.1 Test material

[0034] Hemp oil is obtained by squeezing the hemp seeds purchased in Bama, Guangxi. According to Zhang Chunmei (2008) to the determination method of vegetable oil, the fatty acid composition of hemp oil is as shown in Table 1.

[0035] Table 1 hemp oil fatty acid composition (%)

[0036]

[0037]

[0038] 1.2 Experimental animals and feeding management

[0039] Test location: Cowhouse 1, Cattle Farm, Breeding Demonstration Research Base, Guangxi Buffalo Research Institute, Chinese Academy of Agricultural Sciences

[0040] Experimental animals: 18 buffaloes with three-grade mixed milk (local buffalo x Niri-Rafi buffalo x Mora buffalo)

[0041] Test time: May 18, 2014 - June 28, 2014

[0042] Feeding management: Cattle are under the responsibility of a special person, fed in a single trough ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com