Rectilinear motion linear module and position control servo system provided with module

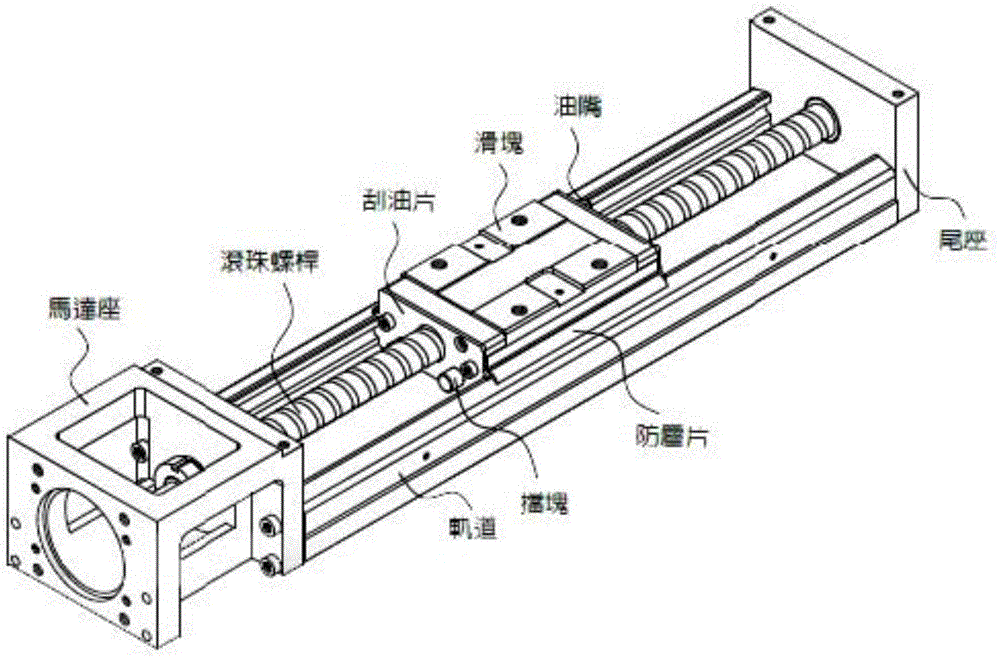

A linear module, linear motion technology, applied in the field of automation, can solve the problems of ball screw implementation length and dimension limitation, difficulty in high-speed operation of the device, difficult ball screw processing, etc., to achieve low cost, high speed, and short response time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

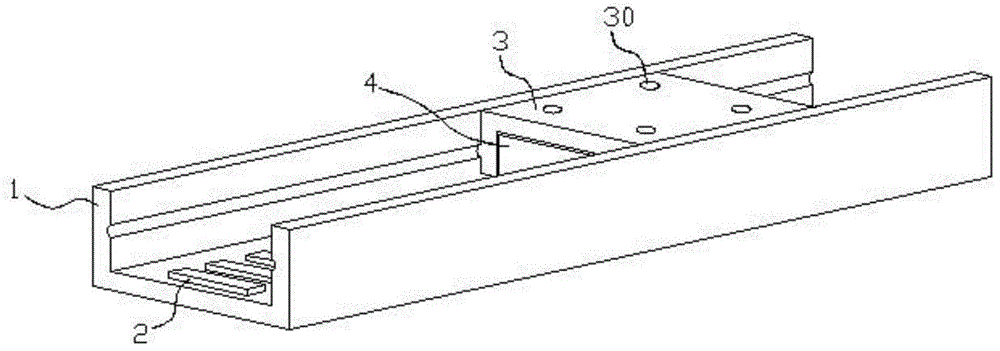

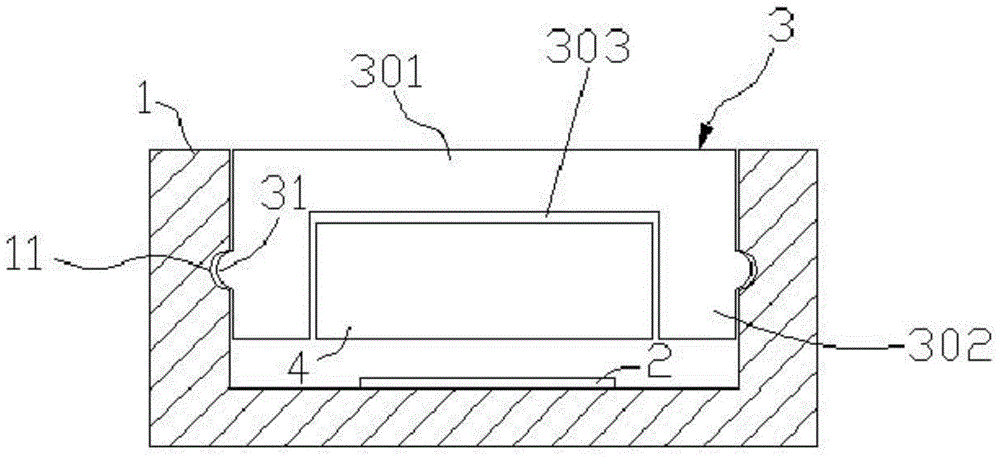

[0033] A linear motion linear module, including a channel-shaped steel body 1 formed by processing pure iron or low-carbon steel, a mover seat 3 that reciprocates on the channel-shaped steel body 1, and a mover seat 3 that cooperates with each other to drive the mover seat 3 moving mover block 4 and stator block 2;

[0034] A group of linear guide grooves 11 are symmetrically arranged on the inner wall of the channel-shaped steel body 1;

[0035] The mover seat 3 is placed in the groove of the channel-shaped steel body 1, and the surface on both sides is provided with a guide structure matching the guide groove 11 of the channel-shaped steel body 1, and the guide structure is convexly arranged on the The surface of the mover seat 3, the protrusion or convex line 31 embedded and sliding along the guide groove 11 of the channel steel body 1; the surface of the guide groove 11 or protrusion adopts laser quenching or other forms of surface hardening and wear resistance deal with....

specific Embodiment 2

[0042] The difference from the above-mentioned specific embodiment 1 is that the inner side wall of the channel-shaped steel body 1 is provided with a straight-line guide rail 12, and the mover seat 3 is placed in the groove of the channel-shaped steel body 1. The surface on both sides is provided with a guiding structure matching the guiding convex rail 12 of the channel-shaped steel body 1. a groove 32 into which the rail 12 fits and slides;

[0043] The guide rail 12 of the channel-shaped steel body 1 and the groove 32 of the mover seat 3 are in a "U" shape or a "V" shape or other combined shapes that cooperate with each other.

specific Embodiment 3

[0045] The difference from the above-mentioned specific embodiment 1 is that balls 5 are arranged between the guide groove 11 of the channel-shaped steel body 1 and the protruding line 31 of the mover seat 3, and single or multiple rows of balls 5 and the guide groove are used. 11, the rolling contact is used to reduce the frictional force between the convex strip 31 and the guide groove 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com