A cork detection system for a filling and corking machine

A filling and stoppering and detection system technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of dropping on the stoppering station, bottles can not be one-to-one correspondence, waste, etc., to prevent the waste of liquid medicine, improve accuracy, The effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

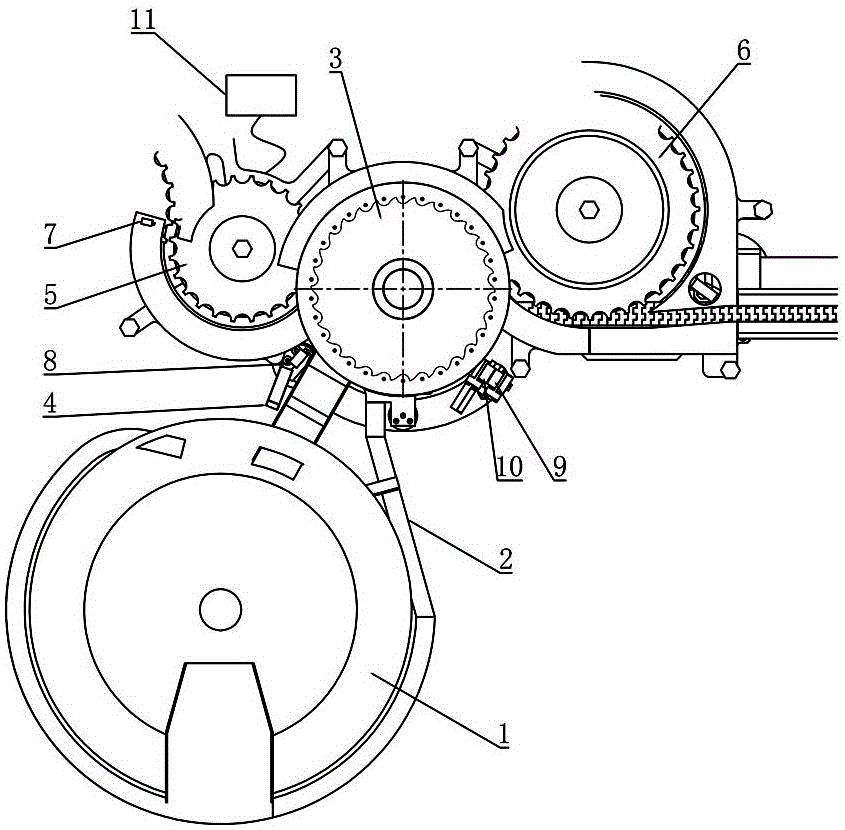

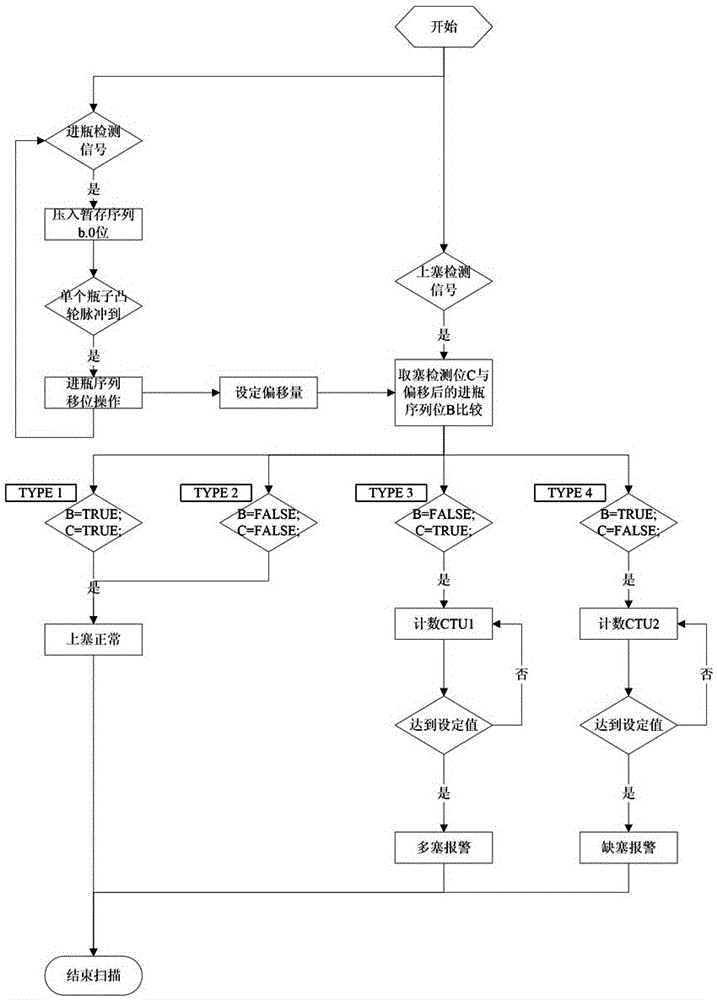

[0017] Such as figure 1 and figure 2 As shown, the cork detection system of the filling and corking machine of the present embodiment includes a control assembly 11 and a first detection assembly 7, and the first detection assembly 7 is used to detect whether there is a bottle on the bottle feeding assembly 5 of the corking machine, and The bottle entry detection signal is sent to the control assembly 11, and the control assembly 11 generates a bottle entry sequence according to the bottle entry detection signal to control whether the plug assembly 1 is plugged. In addition, the detection system also includes a second detection assembly 8. The second detection assembly 8 uses It detects whether there is a cork on the cork assembly 3 between the plugging station and the stoppering station, and sends the cork detection signal to the control ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com