Nameplate printing device for back cover of television set

A technology for printing devices and televisions, which is applied to printing devices, printing, typewriters, etc., can solve the problems of low production efficiency, prolonging the manufacturing time of TV shells, wasting manpower and material resources, etc., to improve the success rate, shorten production time, and improve The effect of marking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

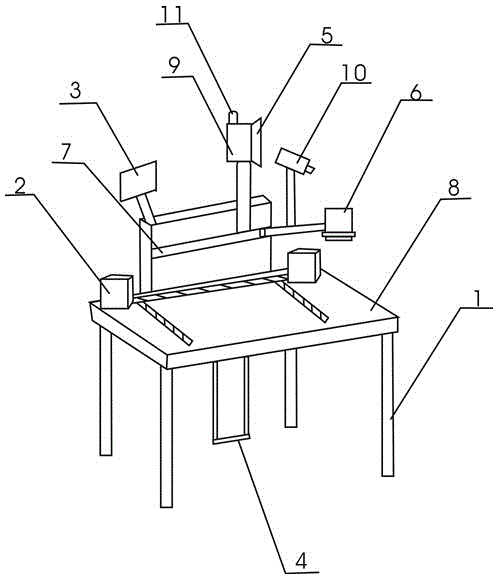

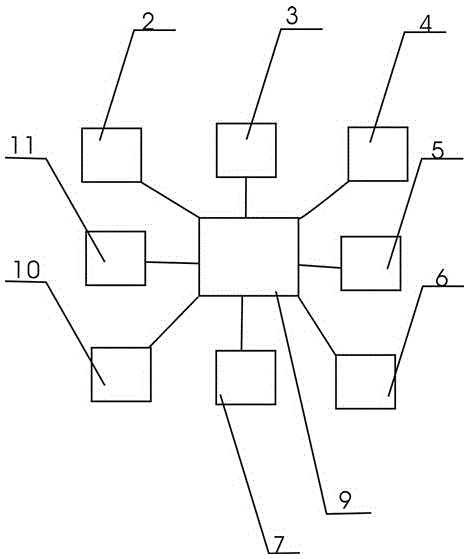

[0011] The invention provides a nameplate printing device for the back cover of a television set, which includes a bracket 1, a calibrator 2, a counter 3, a drive board 4, a display screen 5, a marker 6, a moving shaft 7, a workbench 8, a controller 9, Camera 10, alarm 11, drive plate 4 is installed on the lower side of support 1, workbench 8 is installed on the upper side of support 1, calibrator 2 is installed on the workbench 8, counter 3 and display screen 5 are installed on the upper side of calibrator 2 , a controller 9 is installed on the rear side of the display screen 5, a moving shaft 7 is installed on the lower side of the display screen 5, a marking device 6 is installed on the moving shaft 7, a camera 10 is connected to one side of the marking device 6, and a camera 10 is connected to the upper side of the display screen 5. An alarm 11 is installed, and the controller 9 is respectively connected with the calibrator 2, the counter 3, the driving board 4, the display...

Embodiment 2

[0013] When in use, open the present invention, input the control instruction on the display screen 5, the display screen 5 transmits the control instruction to the controller 9, place the TV shell on the workbench 8, and calibrate it through the calibrator 2. After the calibration is completed, step on the Press the driving board 4, the driving board 4 drives the marking device 6 to act, and the marking device 6 marks the TV casing. In the marking project, the camera 10 shoots it, which is convenient for the staff to observe it. When a problem occurs in the present invention, the controller 9 transmits a signal to the alarm 11, and the alarm 11 sends an alarm to remind the staff to maintain it. The present invention is provided with a calibrator 2, and the calibrator 2 calibrates the position of the TV case on the workbench 8, avoiding wrong positions during marking, ensuring correct marking, and improving the success rate of marking. The present invention also has a counter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com