An electric tightening machine tooling and its method for tightening automobile front axle bolts

A tightening machine, electric technology, applied in metal processing, manufacturing tools, metal processing equipment and other directions, can solve the problems of low efficiency, low tightening quality, and large workload, and achieve the effect of improving work efficiency and tightening quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

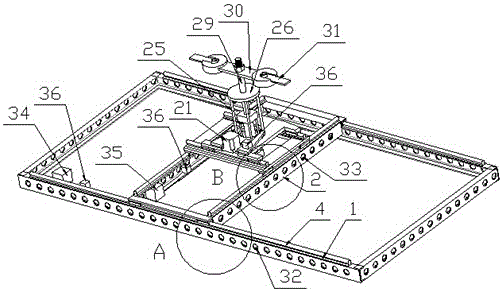

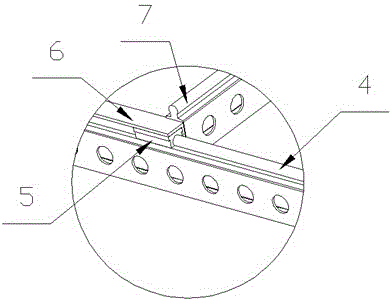

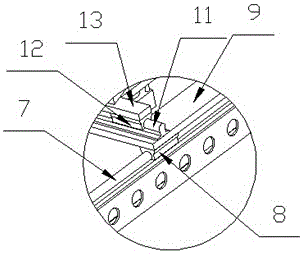

[0033] see Figure 1-Figure 5 , an electric tightening machine tooling, including a beam 1, a longitudinal beam 2 arranged on the beam 1, a tightening device 3 connected to the longitudinal beam 2, a guide rail A4 is fixedly connected to the beam 1, and a guide rail A4 is provided on the guide rail A4 to cooperate with the guide rail A4. The sliding block A5 is provided with a connecting plate 6, and the cross section of the connecting plate 6 is L-shaped. One side of the connecting plate 6 is fixedly connected with the sliding block A5, and the other side is provided with a longitudinal beam 2. The guide rail B7 is fixedly connected, the guide rail B7 is provided with a sliding block B8 cooperating with the guide rail B7, the said tightening device 3 is fixedly connected on the sliding plate B8, the tightening device 3 includes a base plate 9, and the center of the base plate 9 is provided with a lifting hole A10, The base plate 9 is also provided with a guide rail C11, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com