Flavor yogurt containing orange peels and orange peel extract and preparation method thereof

An extract and orange peel technology, applied in the field of flavored yogurt and its preparation, can solve the problems of simple nutrition, single taste, single function, etc., and achieve the effects of high nutritional quality, strong flavor, and compensation for single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

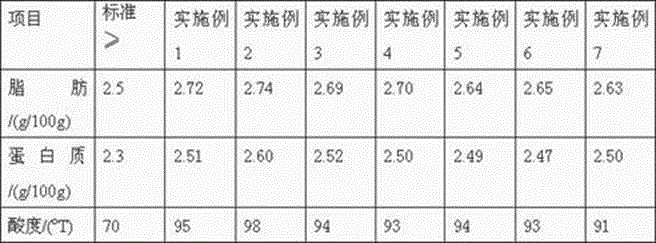

Examples

Embodiment 8

[0039] The method for preparing the flavored yoghurt containing orange peel and orange peel extract described in Examples 1 to 7 is carried out in the following steps:

[0040] 1) Acceptance, cleaning and standardization of fresh milk to obtain standardized fresh milk;

[0041] 2) Prepare orange peel and orange peel extract; add orange peel, orange peel extract, and β-cyclodextrin in sequence to the standardized fresh milk obtained in step 1), stir to mix evenly, and control the temperature to 50°C. Stirring time was 20 minutes to obtain mixture I;

[0042] 3) Mixture I was sterilized at 85°C for 25 minutes, cooled to 41°C, and then introduced into Lactobacillus bulgaricus and Streptococcus thermophilus, the mixing ratio of Lactobacillus bulgaricus and Streptococcus thermophilus was 1:0.8, The amount of inoculum accounts for 4% of the volume of the fermentation broth, which is sufficiently uniform to obtain mixture II;

[0043] 4) The mixture II obtained in step 3) is subjec...

Embodiment 9

[0046] The method for preparing the flavored yoghurt containing orange peel and orange peel extract described in Examples 1 to 7 is carried out in the following steps:

[0047] 1) Acceptance, cleaning and standardization of fresh milk to obtain standardized fresh milk;

[0048]2) Prepare orange peel and orange peel extract; add orange peel, orange peel extract, and β-cyclodextrin to the standardized fresh milk obtained in step 1) in sequence, stir to mix evenly, and control the temperature to 55°C. Stirring time was 15 minutes to obtain mixture I;

[0049] 3) The mixture I was sterilized at a temperature of 90°C for 20 minutes, cooled to 40°C, and then added with Lactobacillus bulgaricus and Streptococcus thermophilus, the mixing ratio of Lactobacillus bulgaricus and Streptococcus thermophilus was 1:0.8, The amount of inoculum accounts for 3% of the volume of the fermentation broth, which is sufficiently uniform to obtain mixture II;

[0050] 4) The mixture II obtained in st...

Embodiment 10

[0052] The method for preparing the flavored yoghurt containing orange peel and orange peel extract described in Examples 1 to 7 is carried out in the following steps:

[0053] 1) Acceptance, cleaning and standardization of fresh milk to obtain standardized fresh milk;

[0054] 2) Prepare orange peel and orange peel extract; add orange peel, orange peel extract, and β-cyclodextrin in sequence to the standardized fresh milk obtained in step 1), stir to mix evenly, and control the temperature at 52°C. Stirring time was 18 minutes to obtain mixture I;

[0055] 3) Mixture I was sterilized at 90°C for 20 minutes, cooled to 43°C, and then introduced into Lactobacillus bulgaricus and Streptococcus thermophilus, the mixing ratio of Lactobacillus bulgaricus and Streptococcus thermophilus was 1:0.8, The amount of inoculum accounts for 5% of the volume of the fermentation broth, which is sufficiently uniform to obtain mixture II;

[0056] 4) The mixture II obtained in step 3) is subjec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com