A method of finding a feature using a machine tool

A machine tool, application and installation technology, applied in the field of scanning measurement tools to identify objects, can solve the problems of long measurement time and slow measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

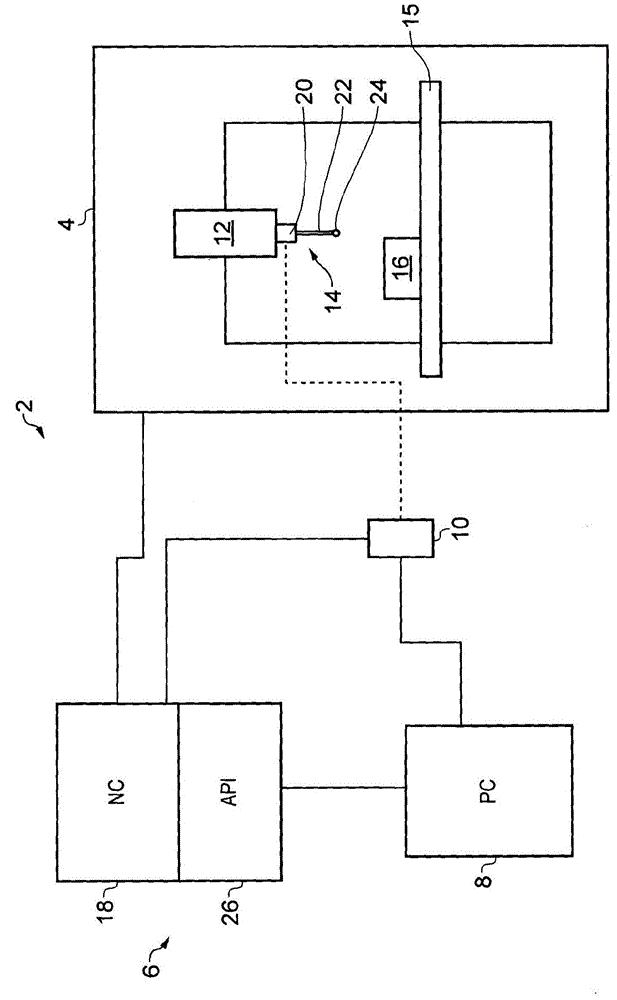

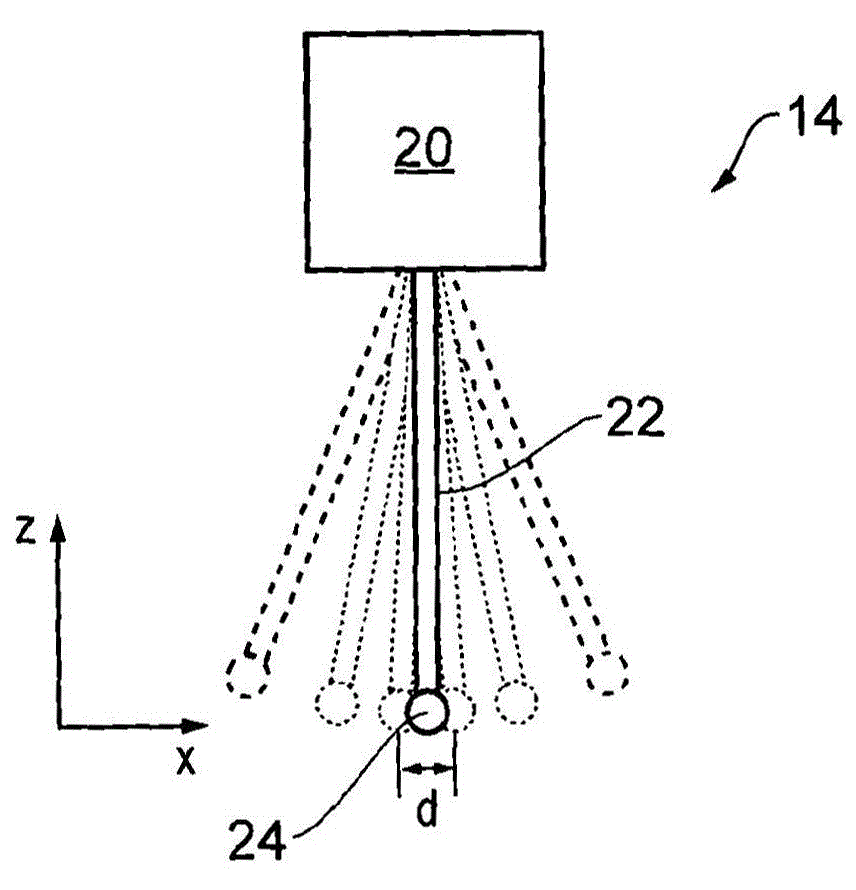

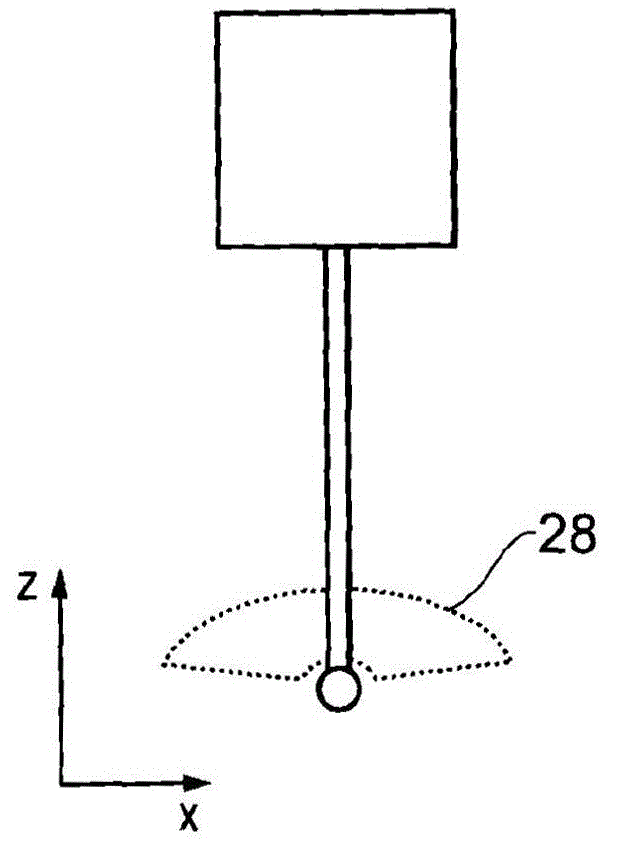

[0048] refer to figure 1 , shows a machine tool installation 2 comprising a machine tool 4 , a controller 6 , a PC 8 and a transmitter / receiver interface 10 . The machine tool 4 includes a motor (not shown) for moving a spindle 12 holding a dummy probe 14 relative to a workpiece 16 positioned on a table 15 . The position of the spindle 12 (and thus the analog probe 14) is precisely measured in a known manner using an encoder or the like. This measurement provides spindle position data defined in the machine coordinate system (x, y, z). A numerical controller (NC) 18 (which is part of the controller 6 ) controls the x, y, z movement of the spindle 12 in the working area of the machine tool and also receives data on the position of said spindle.

[0049]As will be appreciated, in alternative embodiments, relative motion in any or all of the x, y, z dimensions may be provided by motion of the table 15 relative to the spindle. Furthermore, relative rotational motion of simula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com