Single-unit single-person-on-duty thermal power single-control console

A single console and unit technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve problems such as the inability to realize single-person operation station thermal power units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

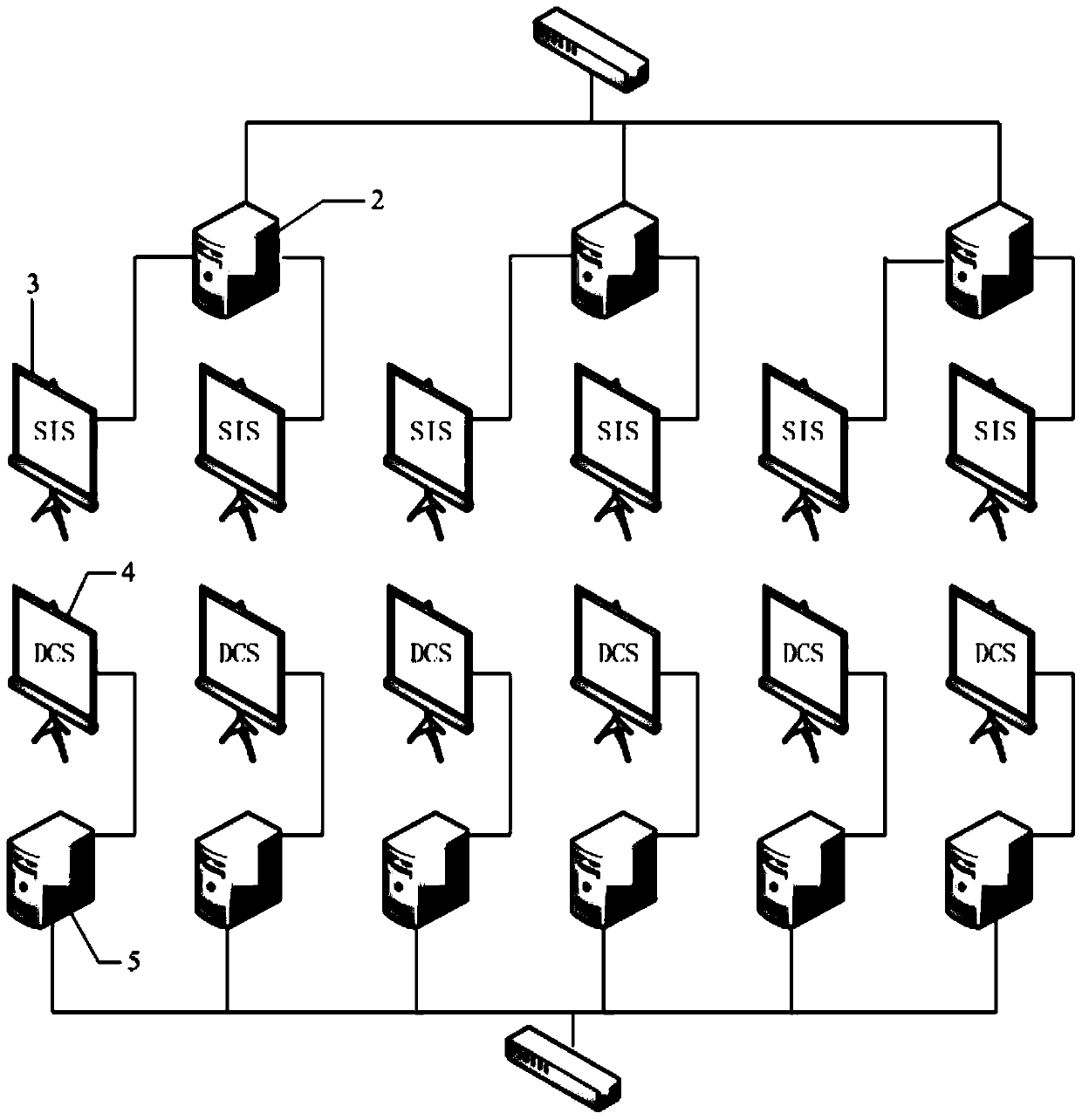

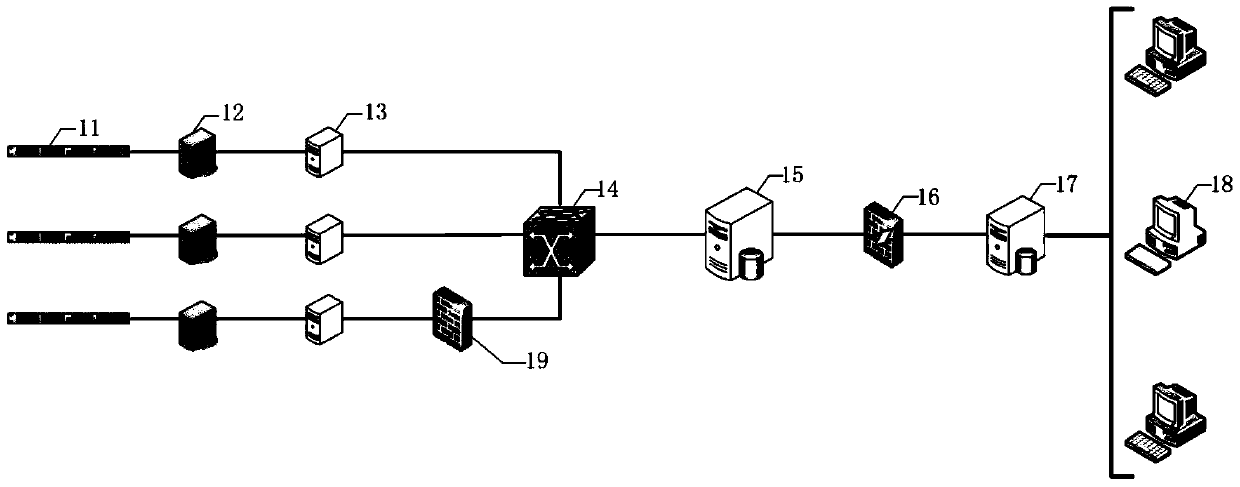

[0025] Specific implementation mode 1. Combination Figure 1 to Figure 4 Illustrate this specific implementation mode, the single control station of thermal power generation with single unit on duty, which includes A real-time database client computers 2, A or 2A real-time database client displays 3, B DCS operating stations 5 and B A DCS display 4; A and B are both positive integers;

[0026] The A real-time data client computers 2 are all connected to the MIS network; the display signal input terminals of each or two real-time data client displays 3 are connected with the display signal output terminals of a real-time data client computer 2;

[0027] The B DCS operation stations 5 are all connected to the DCS network, and the display signal input ends of the B DCS operation stations 5 are respectively connected with the display signal output ends of the B DCS displays 4;

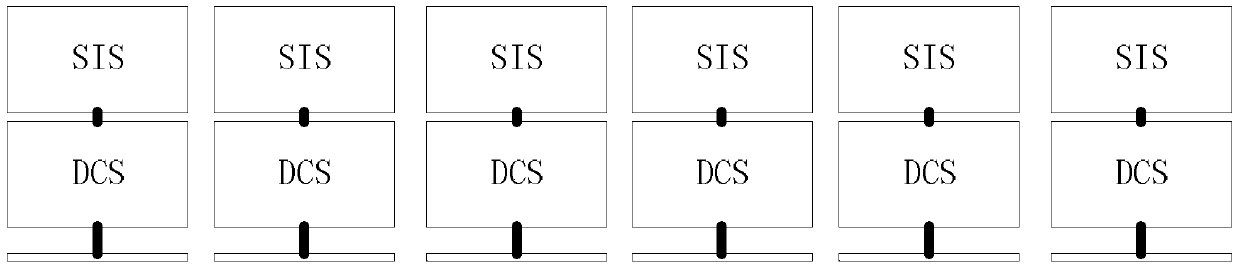

[0028] It is characterized in that: A or 2A real-time data client displays 3 are arranged in a row or ...

specific Embodiment approach 2

[0033] Specific Embodiment 2. The difference between this specific embodiment and the single-unit, single-person-attended thermal power generation single console described in specific embodiment 1 is that it also includes a double-layer display bracket, and the double-layer display bracket A or 2A real-time data client displays 3 are placed on the upper layer of the double-layer display bracket; B DCS displays 4 are placed on the lower layer of the double-layer display bracket.

specific Embodiment approach 3

[0034] Specific embodiment three, the difference between this specific embodiment and the single-unit single-person duty thermal power single console described in specific embodiment one is that the trend screen of the trend screen generation module on the real-time database client display 3 is divided into four Each area displays a group of power generation trends, and each group of power generation trends displays 15 to 25 power generation trend curves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com