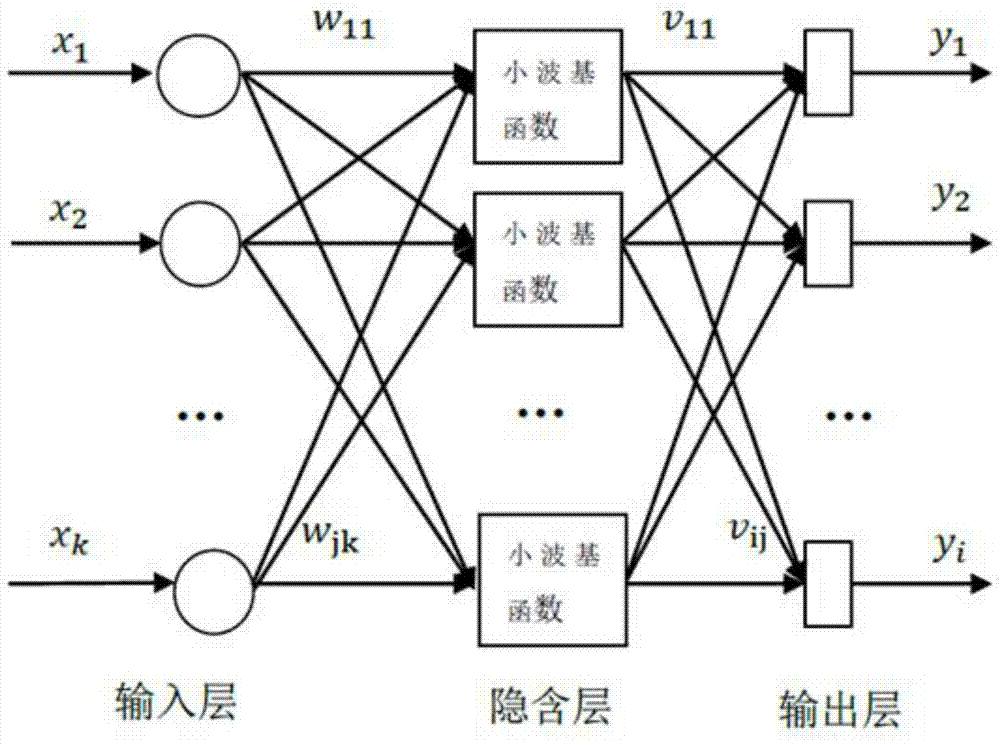

A method for predicting variable load rate of thermal power units based on wavelet neural network

A technology of wavelet neural network and thermal power unit, which is applied in the direction of instruments, adaptive control, control/regulation system, etc., can solve the problems of unfavorable intelligent control of thermal power plants and unsatisfactory precise control, and achieve intelligent prediction methods, Active prediction and high prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be further introduced below in combination with specific embodiments.

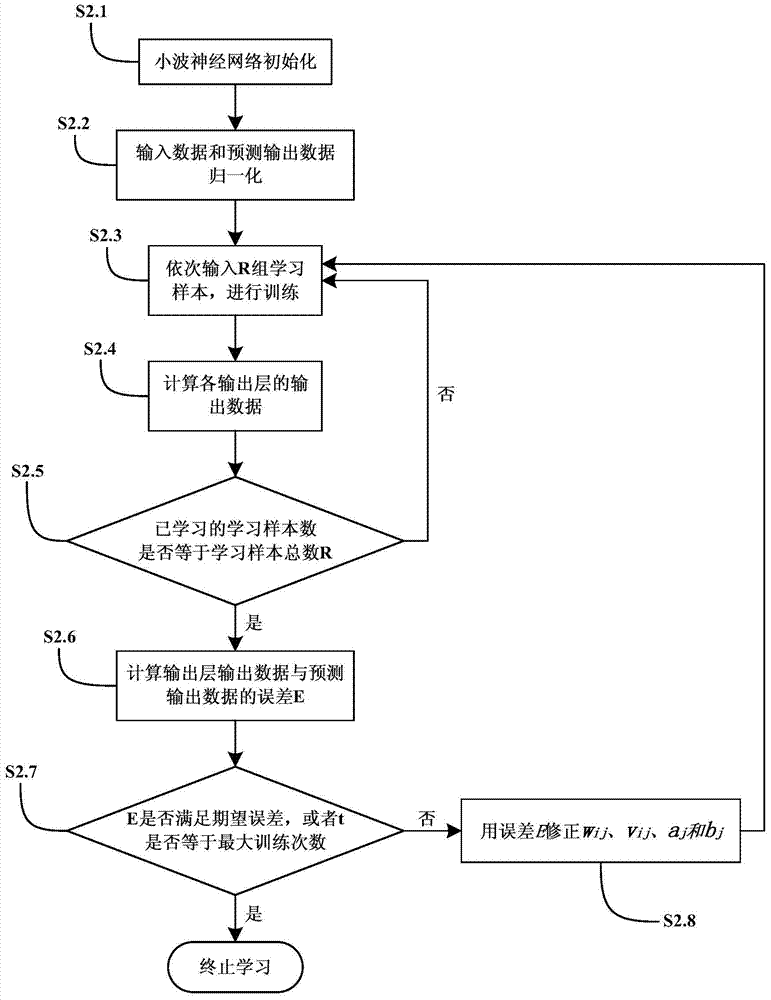

[0039] The invention provides a method for predicting variable load rate of thermal power units based on wavelet neural network, comprising the following steps:

[0040] S1: Select the variable load target instruction, current load, current main steam pressure value and BTU coal quality correction coefficient at a load change moment from the DCS system of the thermal power plant as input data, select the time interval as 10s, and According to the actual load curve of the thermal power unit at this load change moment, the variable load rate d is obtained 1 As the predicted output data, and R=200 groups (x 1 , x 2 , x 3 , x 4 , d 1 ) 1 ,(x 1 , x 2 , x 3 , x 4 , d1 ) 2 ,...,(x 1 , x 2 , x 3 , x 4 , d 1 ) R As learning samples, Q=20 groups (x 1 , x 2 , x 3 , x 4 , d 1 ) 1 ,(x 1 , x 2 , x 3 , x 4 , d 1 ) 2 ,...,(x 1 , x 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com