A firecracker automatic charging and sealing machine

A sealing machine, automatic technology, applied in the direction of fireworks, offensive equipment, weapon types, etc., can solve the problems of low quality of firecracker products, serious environmental pollution, low charging accuracy, etc., to reduce the cost of gunpowder, reduce dust flying, equipment The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

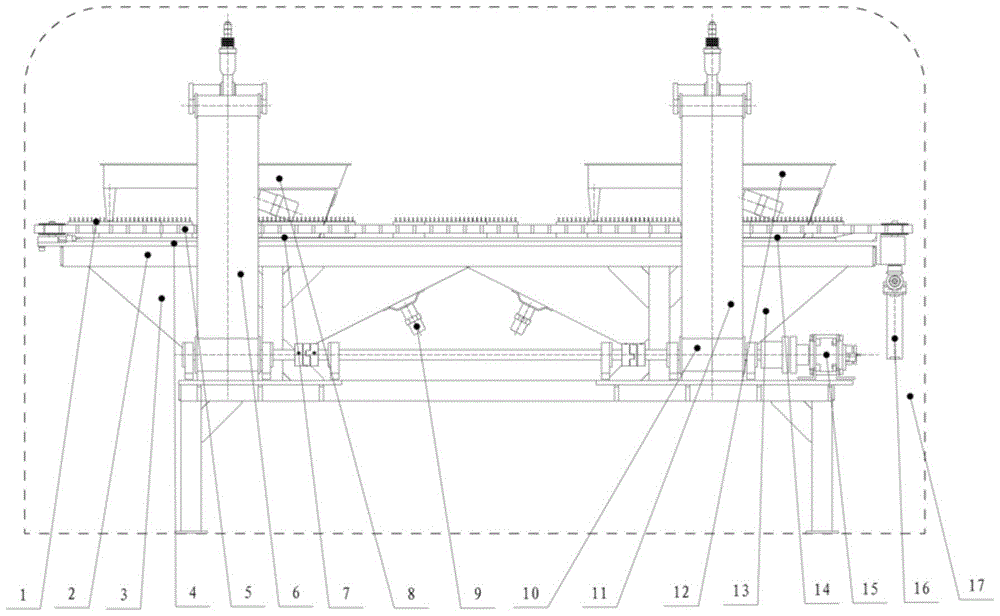

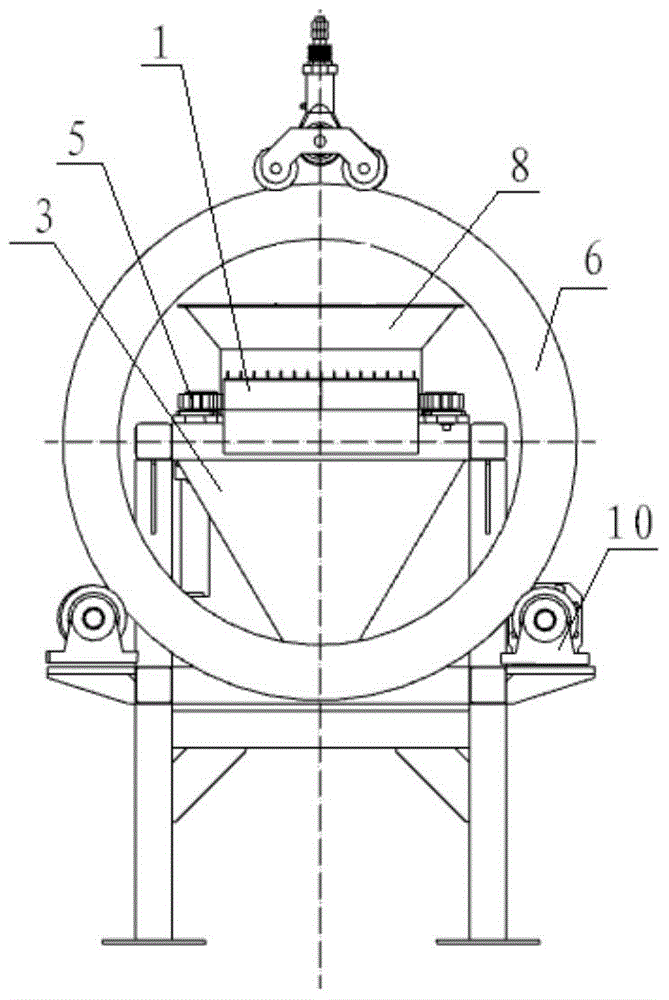

[0016] Such as figure 1 As shown, the present invention provides a kind of firecracker automatic charging and sealing machine, mainly by workbench 2, gunpowder collecting bucket 3, grate plate 4, synchronous conveying belt 5, gunpowder return drum 6, gunpowder cleaning machine 7, gunpowder feeding Machine 8, bin wall vibrator 9, support roller 10, sealing medicine return drum 11, sealing medicine feeder 12, sealing collection bucket 13, sealing medicine clearing machine 14, roller driving device 15, transmission synchronous belt driving device 16 Composed of casing 17;

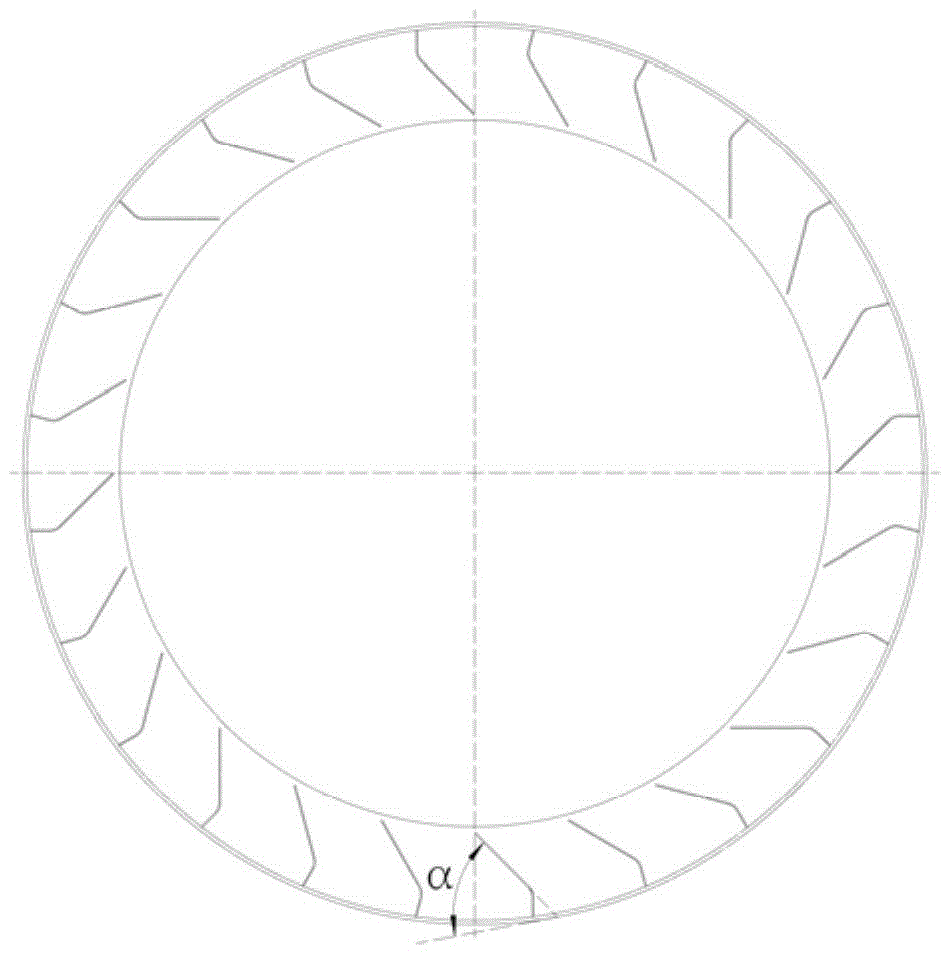

[0017] The workbench 2 is supported by a bracket, and the top surface of the workbench 2 is laid with a grate plate 4. The grate plate 4 is composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com