Downward-pushing magnetic material wet forming hydraulic machine and use method thereof

A magnetic material, wet forming technology, applied in the field of hydraulic presses, can solve the problems of large loss of equipment components, waste of electricity, and damage to the bias voltage of the finished product, and achieve the effect of reducing the forming time, reducing defects such as blank cracks, and improving the magnetic grade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

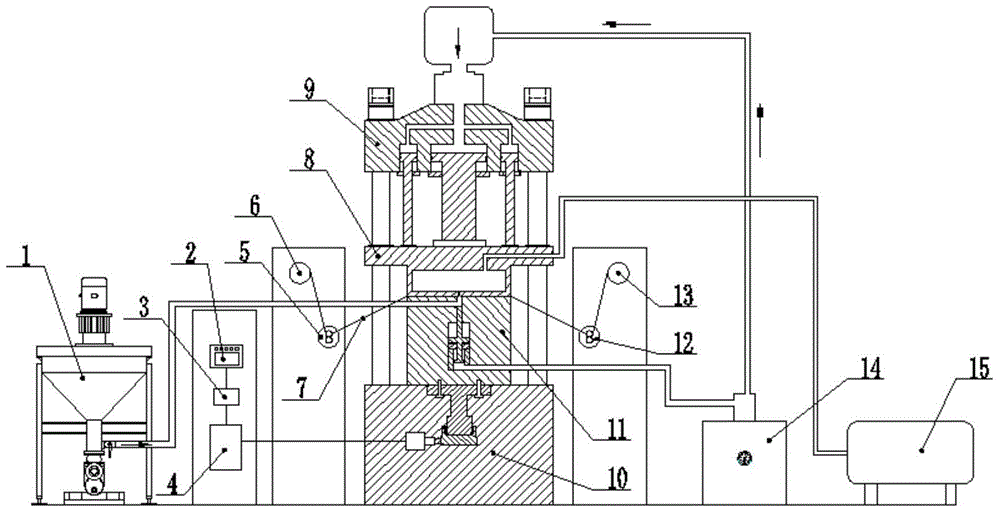

[0057] This design is different from the presses on the market. Through the use of bottom-top pressing process, fixed formwork mechanical limit and automatic adjustment of lower mechanical limit device, large-bore oil cylinder design, filling system with complete separation of slurry and hydraulic oil, servo positioning control system for billet removal, and high-precision double cylinders Balance system, mold surface cleaning micro-electric drive technology scheme, achieve product magnetic grade up to 12, green body thickness error control less than 0.10mm, working pressure down to 26MPa, stable pressing force, lower oil temperature, component loss rate reduced by 50% , Eliminate the pollution source of the slurry to the hydraulic oil, reduce the failure rate of equipment operation and the vulnerable rate of components, reduce the replacement of hydraulic oil, and the positioning error of the blanking system is less than 0.5mm, which can meet the blanking working conditions of...

Embodiment 2

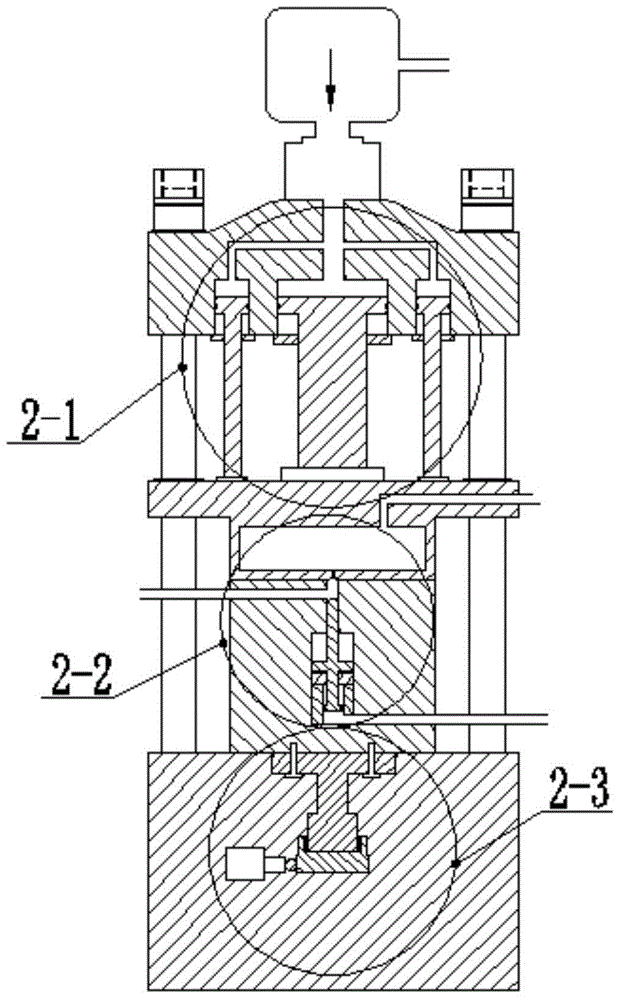

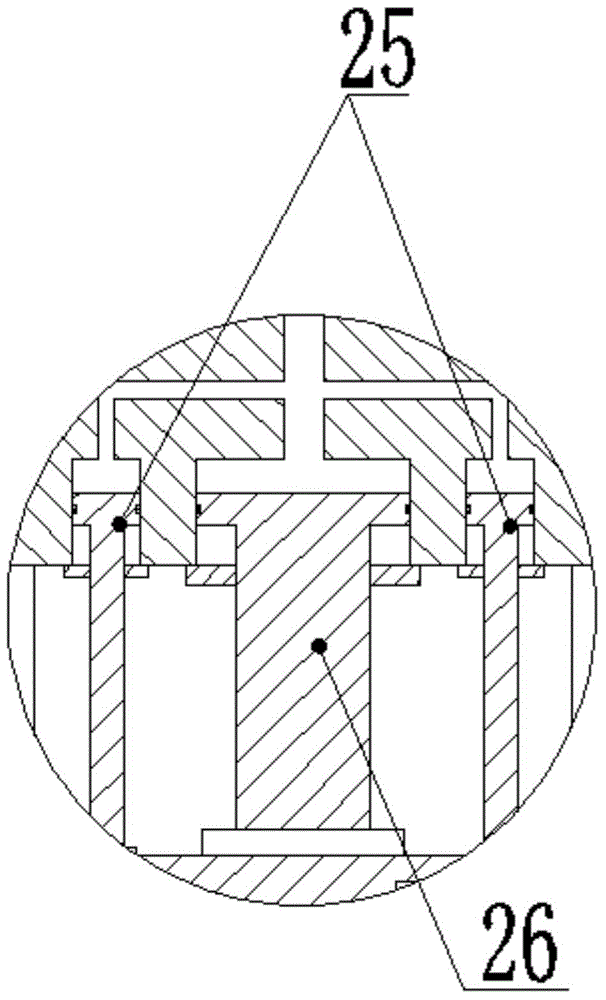

[0083] The structure and method of this embodiment are the same as embodiment 1, figure 2 2-1 in image 3 The reduced graphics of the internal diagram of the upper die base in , 2-2 is Figure 4 The reduced graphics of the internal diagram of the fixed formwork in ; 2-3 are Figure 5 A zoomed-out drawing of the inside view of the die holder in .

[0084] Figure 7 In order to automatically detect the schematic diagram of the fault system, it can detect the disturbance of the pressure of the hydraulic press and the current signal of each performance parameter, that is, output the disturbance signal of the analog quantity, and the signal is sent to the sensor E, A / D module F, I / O module G, decoder H, alarm light I, touch screen 2, PLC3, amplifier C and actuator D; touch screen 2 outputs digital quantities, PLC3 inputs digital quantities, outputs analog disturbances, sensors E, A / D Module F, I / O module G and decoder H are electrically connected in sequence, and the output of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com