Wrap-around automotive spark plug

A spark plug and wraparound technology, which is applied in the field of spark plugs, can solve the problems of increased electrode gap and difficulty in starting the generator, and achieve good ignition stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

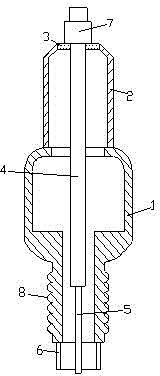

[0010] see figure 1 As shown, a wrap-around automotive spark plug includes a housing 1, the top of the housing 1 is open and the top of the housing 1 is connected to an insulator 2, the top of the insulator 2 is open and the top of the insulator is equipped with a cap 3, and a cap 3 is installed in the cap 3 The conductive rod 4, the lower end of the conductive rod 4 passes through the insulator 2 and then extends into the housing 1, and the lower end of the conductive rod 4 is connected to the intermediate electrode 5, the intermediate electrode 5 passes through the housing 1 from the bottom end of the housing 1, and the bottom of the housing 1 The end is also connected with a ring electrode 6 covering the middle electrode 5 . A ground nut 7 is connected to the top of the insulator 2 , and the upper end of the conductive rod 4 passes through the cap 3 and is connected to the ground nut 7 . External threads 8 are formed on the lower outer wall of the housing 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com