Retest method based on test of multiple points around coordinate position of test point

A technology of multi-point testing and coordinate position, which is applied in the direction of electronic circuit testing, etc., can solve problems such as inability to completely eliminate misjudgment, achieve the effects of reducing mistesting, improving reliability, and solving misjudgment problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

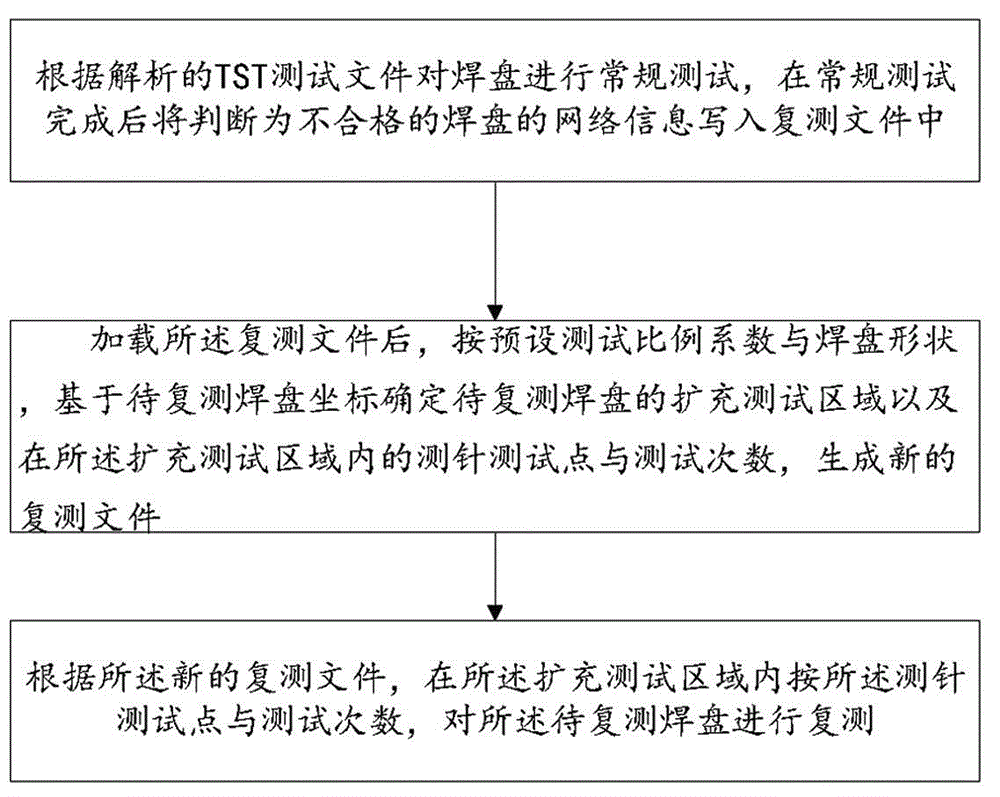

[0035] see figure 1 , a method for retesting based on multi-point testing around the test point coordinate position, comprising the following steps:

[0036] S101: Carry out routine test to pad according to the TST test file of analysis, after routine test is finished, write the netlist information of the unqualified pad into the retest file;

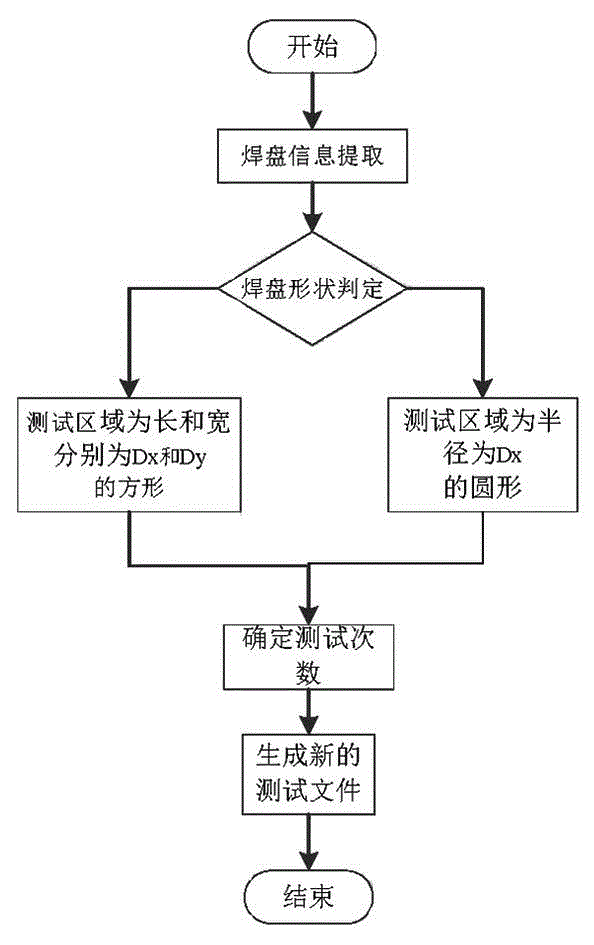

[0037] The parsed TST test file is a test file with pad information, which is parsed and formed by the main program, and is formed through the following steps:

[0038] Analyzing the original process file, obtaining pad information and netlist information, judging the shape of the pad and recording pad shape information data, analyzing and generating the TST test file with pad information.

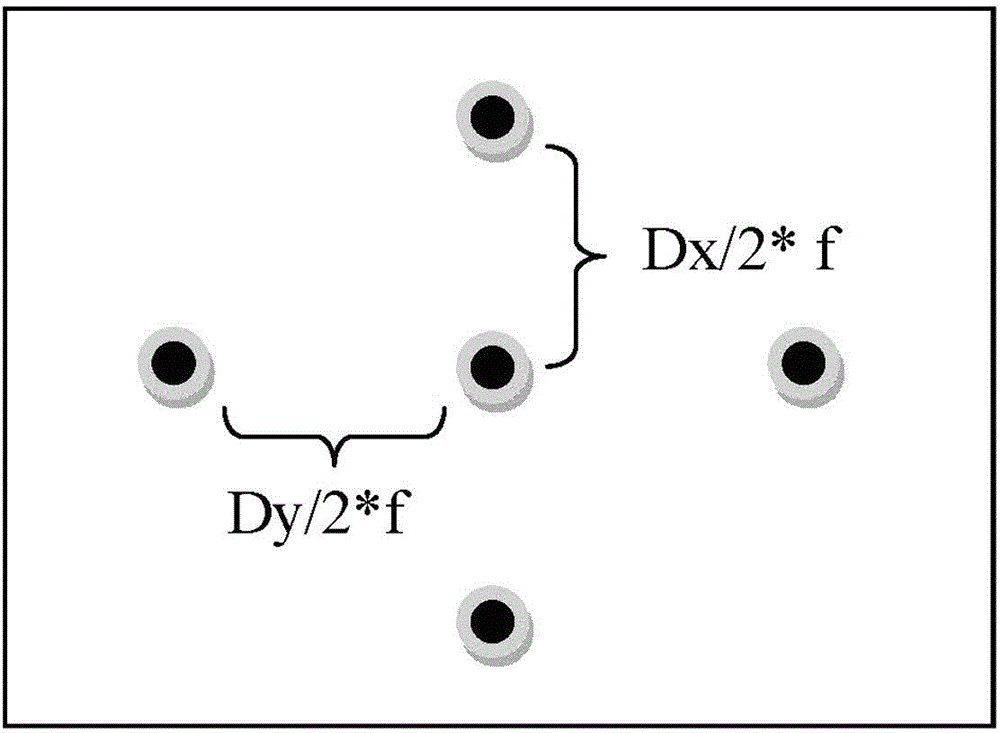

[0039] Specifically, see Figure 6 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com