Electric heater structure for high-viscosity oil products

An electric heater, high viscosity technology, used in water heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as damage to oil and heating equipment, easy coking and carbonization of oil, slow heat conduction, etc. The effect of preventing oil coke, improving heat transfer efficiency and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

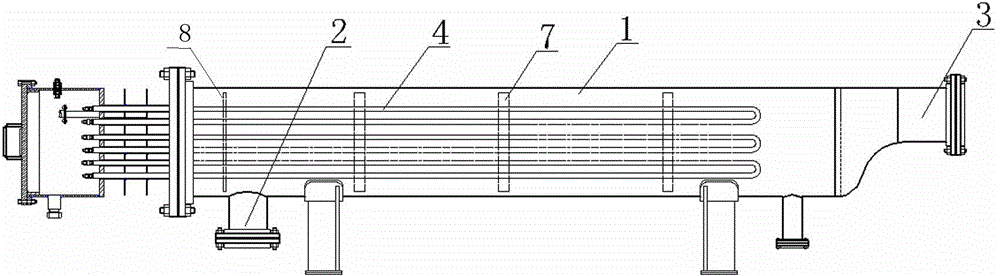

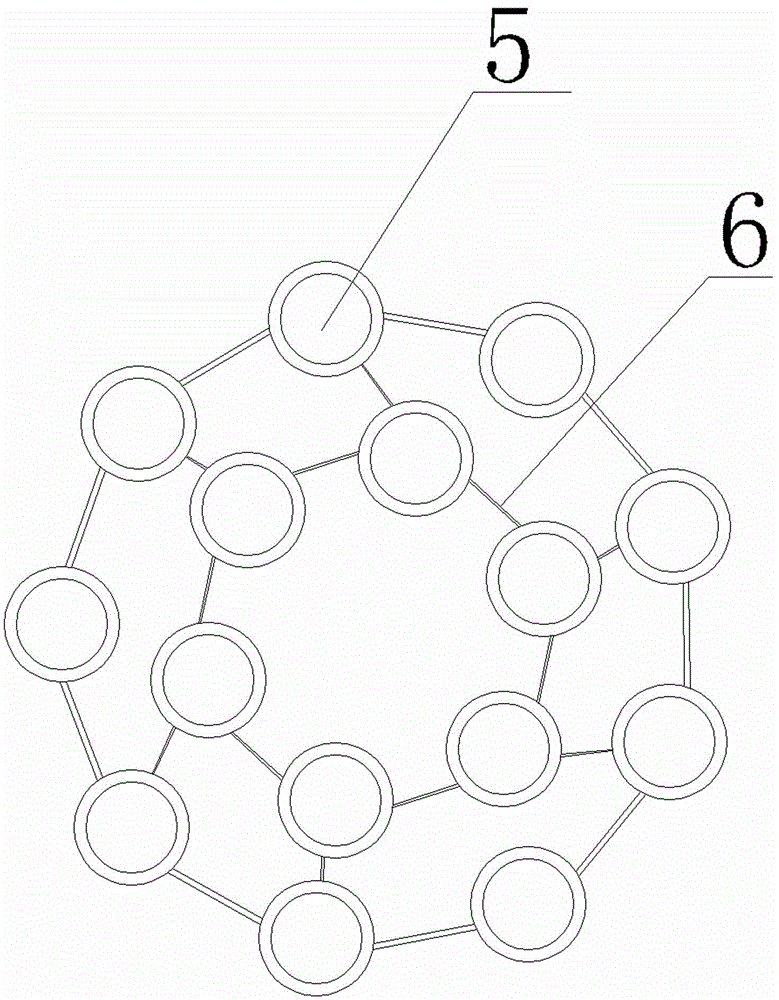

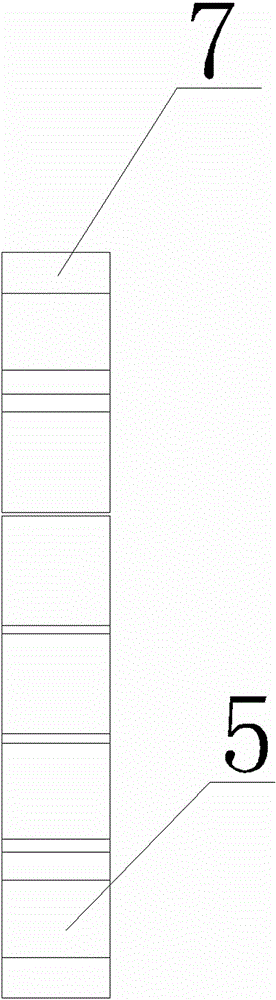

[0010] The structure of the high-viscosity oil electric heater of the present invention is further described below in conjunction with the accompanying drawings:

[0011] See figure 1 , figure 2 and image 3 , a high-viscosity oil electric heater structure, which includes a housing 1, an oil inlet 2, and an oil outlet 3, and a plurality of sets of electric heating tubes 4 are arranged in the housing 1, and the electric heating tubes 4 are respectively arranged on the ferrule 5, the ferrules 5 are connected by the rib plate 6 to form an overall support structure, which increases the liquid flow area and flow speed of the oil passing through the electric heating tube support position, effectively prevents the formation of a liquid flow dead zone in the electric heater, and improves the The heat conduction efficiency of the oil in the electric heating tube prevents the coking of the oil, thus effectively avoiding the damage of the oil and the heating equipment.

[0012] The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com