Quick connection mechanism

A quick connection and articulation technology, which is applied in the direction of mechanical equipment, mechanical drive clutches, and clutches that mesh with each other, can solve problems that affect the life of equipment, have no buffering and load sharing capacity, and complex structure of the connecting mechanism, so as to save time and energy. The effect of simple labor and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The accompanying drawings and the following description are only the basic description of the present invention, and other changes arising therefrom do not depart from the scope of the present invention.

[0023] The present invention is described in detail below in conjunction with accompanying drawing:

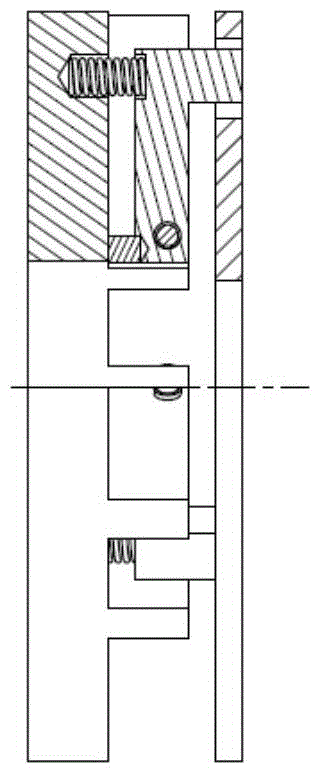

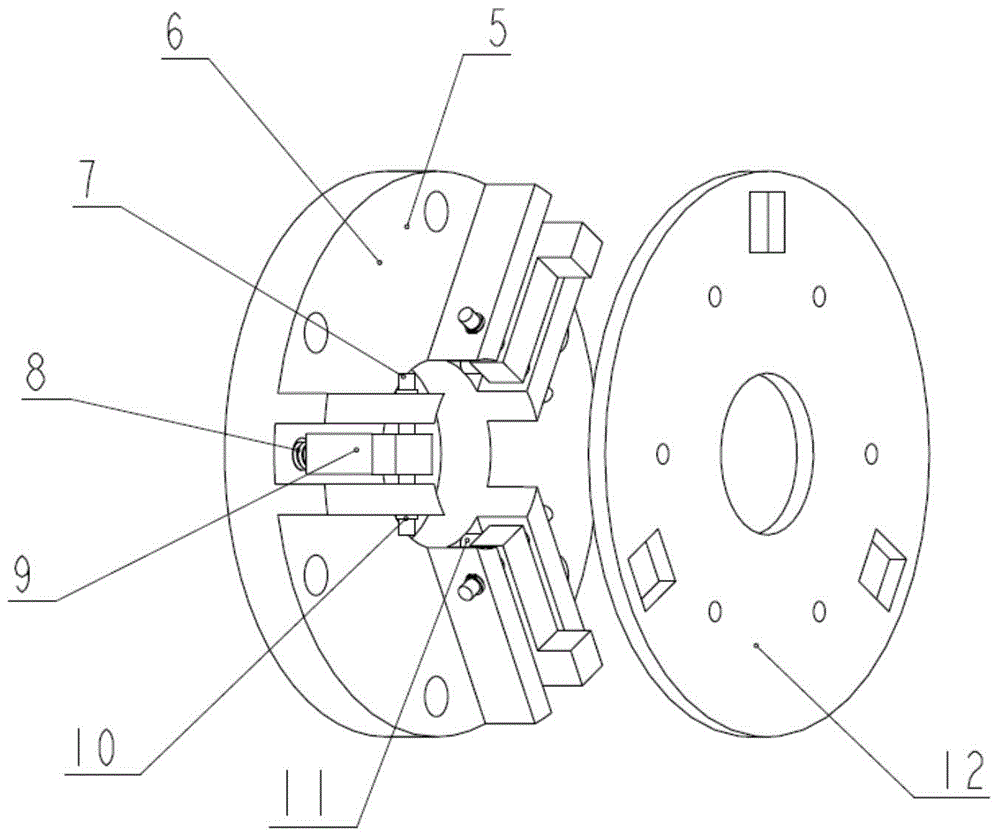

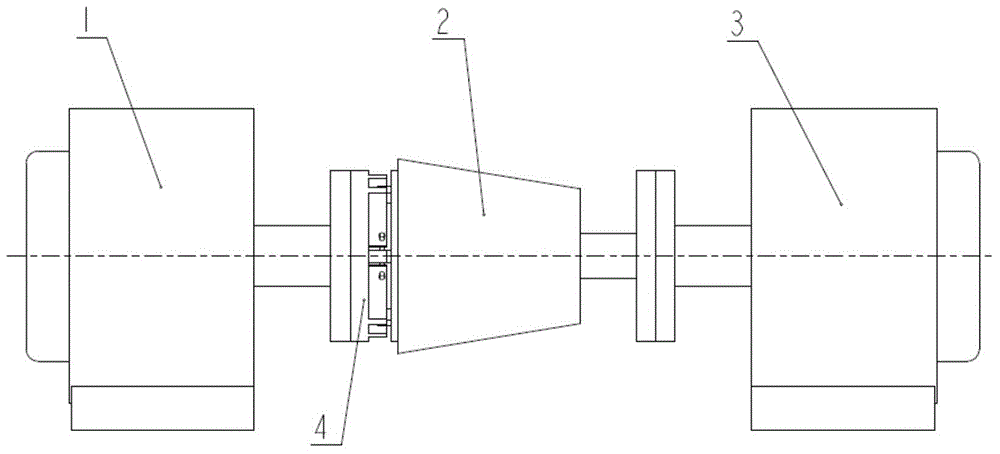

[0024] Such as Figure 1-3 As shown, the present invention discloses a quick connection mechanism, including a driving end 5 and a flexible disc 12 . The drive motor 1 provides speed and torque to drive the drive end 5 to rotate. When the quick connection mechanism 4 is not combined, the flexible disk 12 has no power input, and the flexible disk 12 and the load motor 3 do not operate; when the quick connection mechanism is combined, Under the action of the driving end, the flexible disk transmits the power to the load motor. The quick connection mechanism is applied on the transmission 2 test bench as a detachable accessory device, and is installed on the test bench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com