A sugarcane planter

A planting machine and sugarcane technology, applied in planting methods, plant protection covers, applications, etc., can solve the problems of low seedling emergence rate and low sugarcane planting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

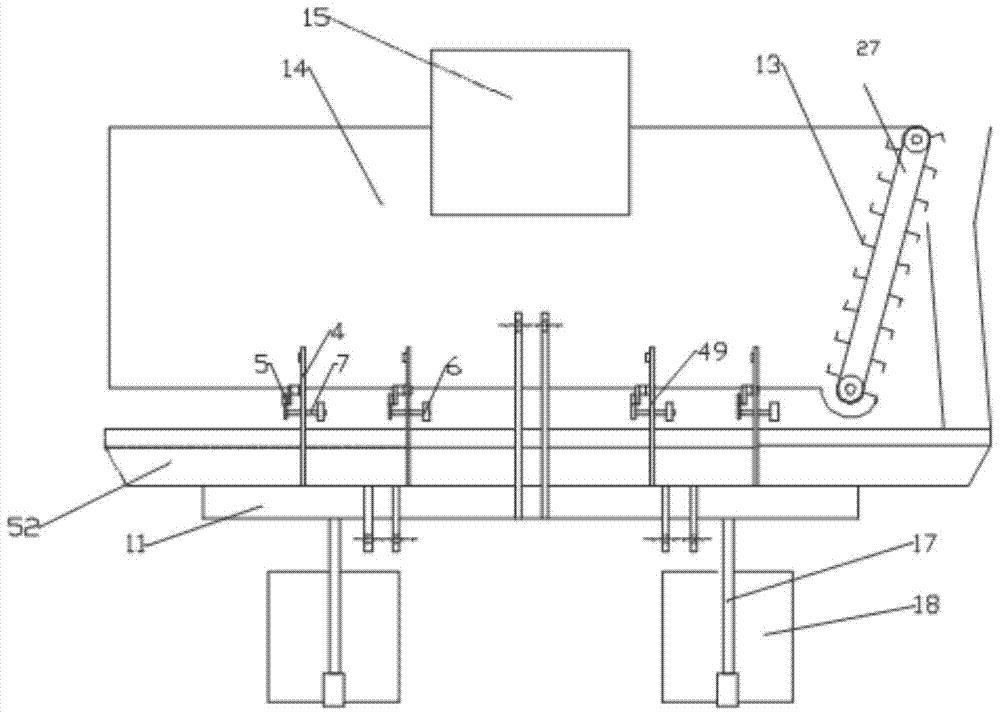

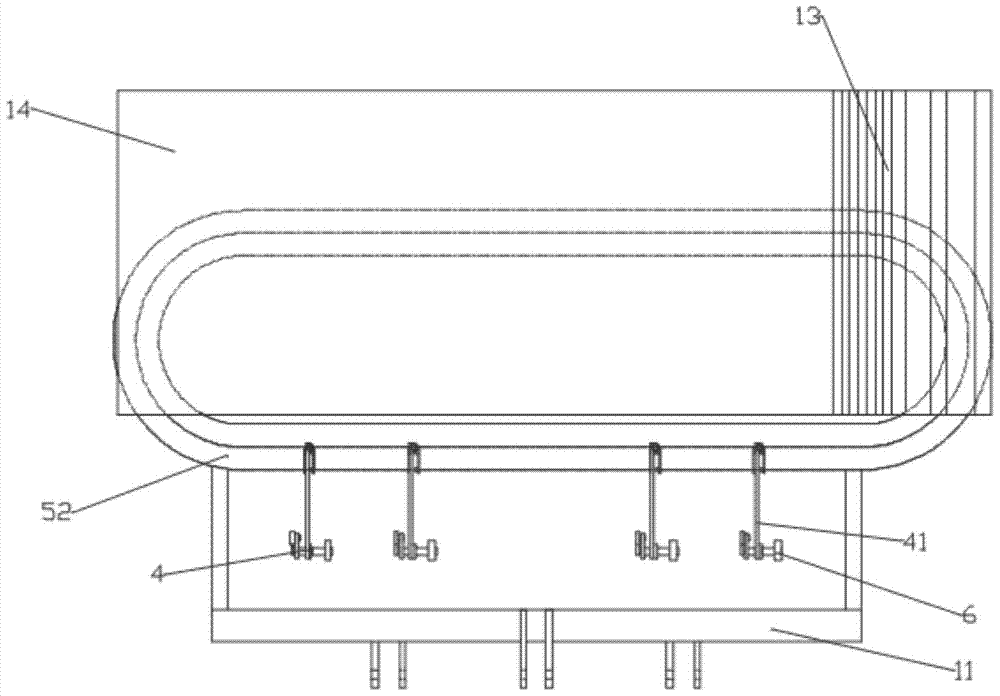

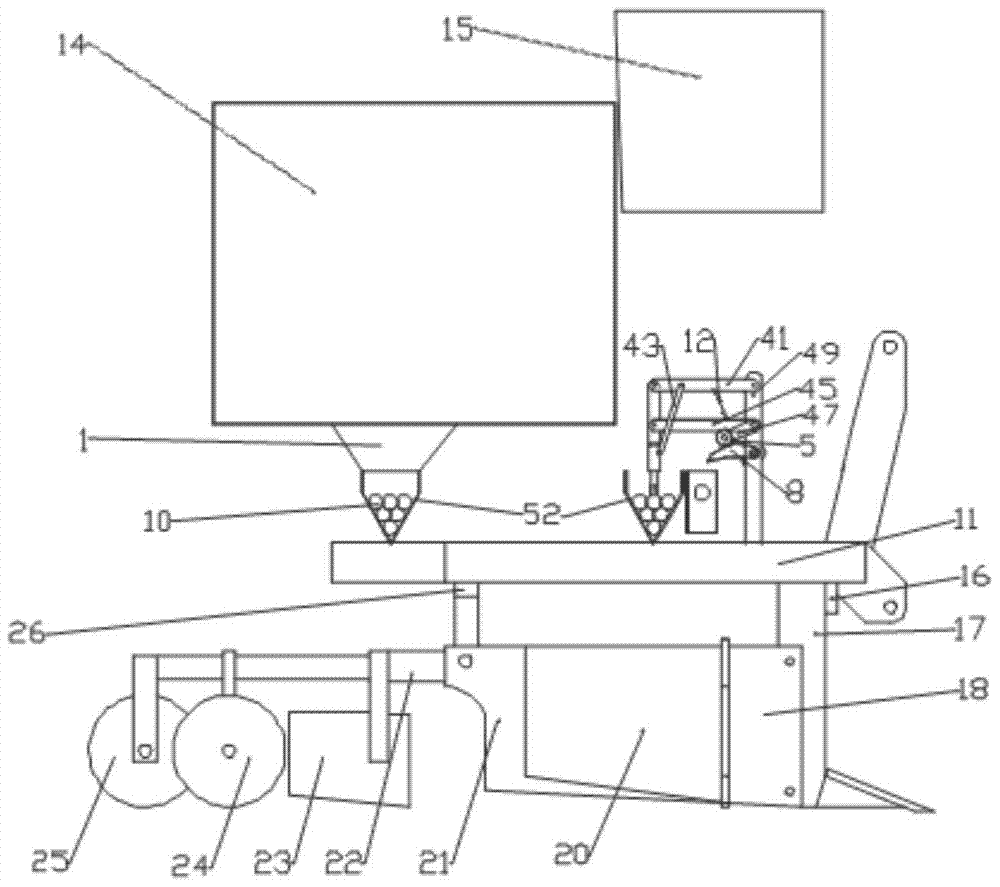

[0036] Such as Figure 1 etc., the sugarcane planter includes a frame, a ditching mechanism, and a film covering mechanism. The seed conveyor belt is connected to the power unit. The sugarcane seed metering device includes a seed guide box for conveying cane seeds to the circular seed picking conveyor belt, a seed guide groove for making the sugarcane seeds fall into the soil, and sharp seed picking parts. The box includes a rear baffle, a left baffle and a right baffle. The rear baffle is placed vertically or obliquely relative to the horizontal direction. The left baffle and the right baffle are placed obliquely relative to the horizontal direction. The edge of the baffle is connected, the right edge of the back baffle is connected with the edge of the right baffle, and the back baffle, the left baffle and the right baffle form a slide shape that is wide at the top and narrow at the bottom that opens toward the front of the back baffle. The end of the circular seeding convey...

Embodiment 2

[0041] Such as Figures 1 to 8 As shown, the frame 11 is provided with a seed guide device, which includes a seed supply box 14 and a seed conveyor belt 27. The input end of the seed conveyor belt 27 is arranged in the seed supply box 14, and the output end is connected to the seed supply box 14. In case 1, seed feeding scoops 13 are provided at intervals outside the belt surface of the seed feeding conveyor belt 27, and the seed feeding spoons can be U-shaped, V-shaped or L-shaped. In this embodiment, the seed guide device is driven by external power equipment to continuously transport sugarcane seeds to the seed box 1 . Improved delivery accuracy and efficiency.

[0042] In Embodiment 1 and Embodiment 2, the rod-shaped transmission mechanism includes a hoe-shaped rod, the seed-taking head is arranged at the end of the hoe-shaped rod, and the seed retreater is a hook-shaped or door frame-shaped component fixed on the frame. Driven by the external power equipment, the rod-sh...

Embodiment 3

[0044] further, such as Figures 1 to 6 As shown, the rod-shaped transmission mechanism is a link mechanism. The sugarcane planter can choose the linkage mechanism as the linkage mechanism. The movement forms of the linkage mechanism components are various, such as rotation, swing, movement and plane or space movement, which can be used to realize the reciprocating motion of the known trajectory. Therefore, the reciprocating motion of "above the circular seed-taking conveyor belt 52 - above the seed guide groove - above the circular seed-picking conveyor belt 52" in Embodiment 1 can be realized by means of a link mechanism. The advantage of linkage mechanism transmission is that it can transmit complex movements. By calculating the length of each connecting rod, more accurate motion transmission can be achieved. Therefore, in the process of controlling the seed taking by the seed taking head and returning the seed with the seed ejector, the error will be smaller.

[0045] F...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap