A kind of sick and dead pig transporter and its operation method

A technology for transporting vehicles and sick and dead pigs, which is applied in the field of pig raising equipment research, can solve the problems of healthy pigs being susceptible to diseases, increasing labor intensity, and increasing labor costs, and achieves the effects of simple operation, improved efficiency, and reduced labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

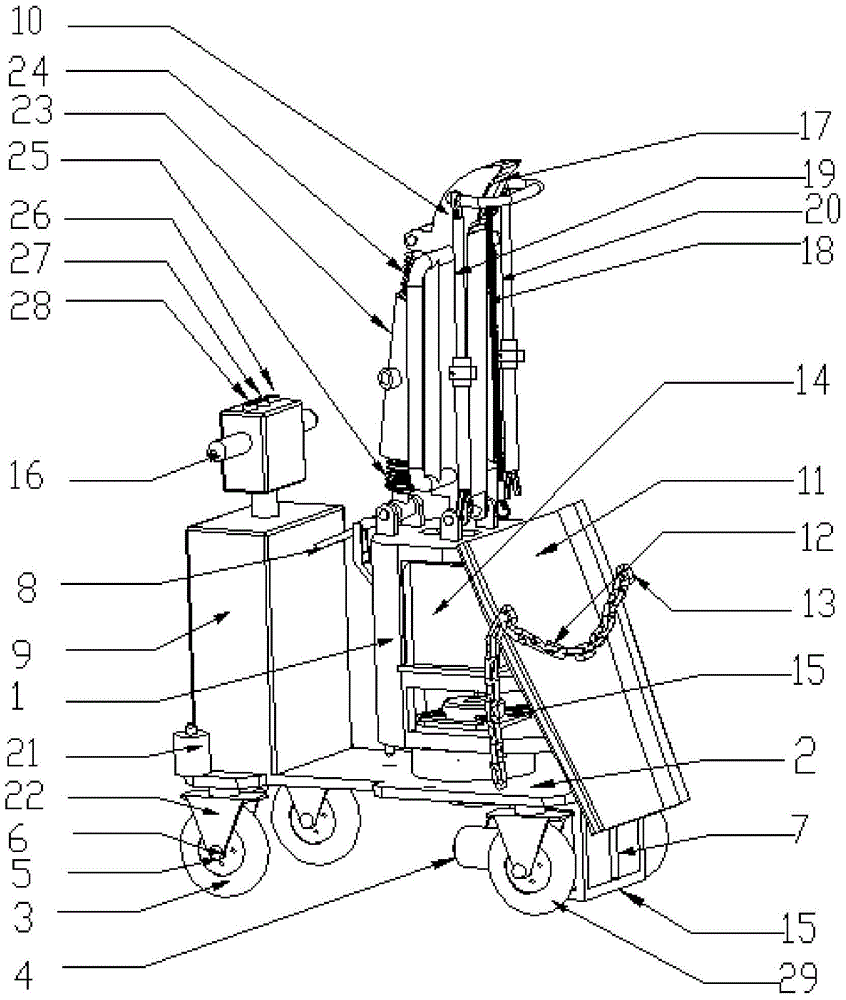

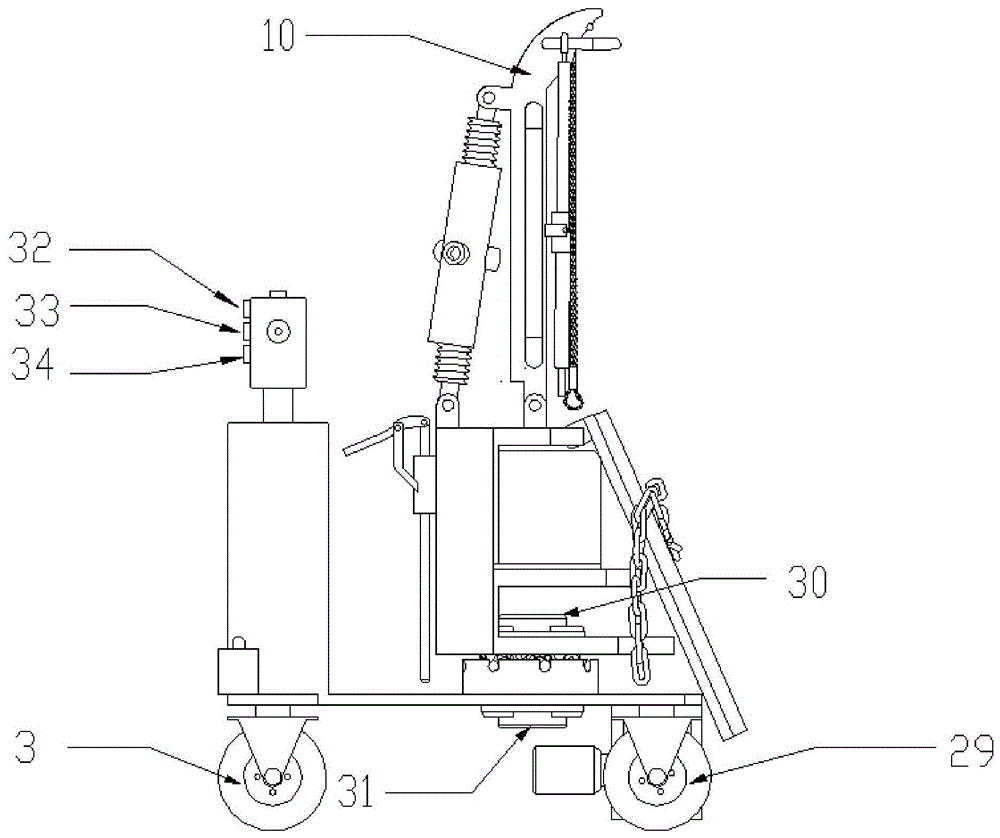

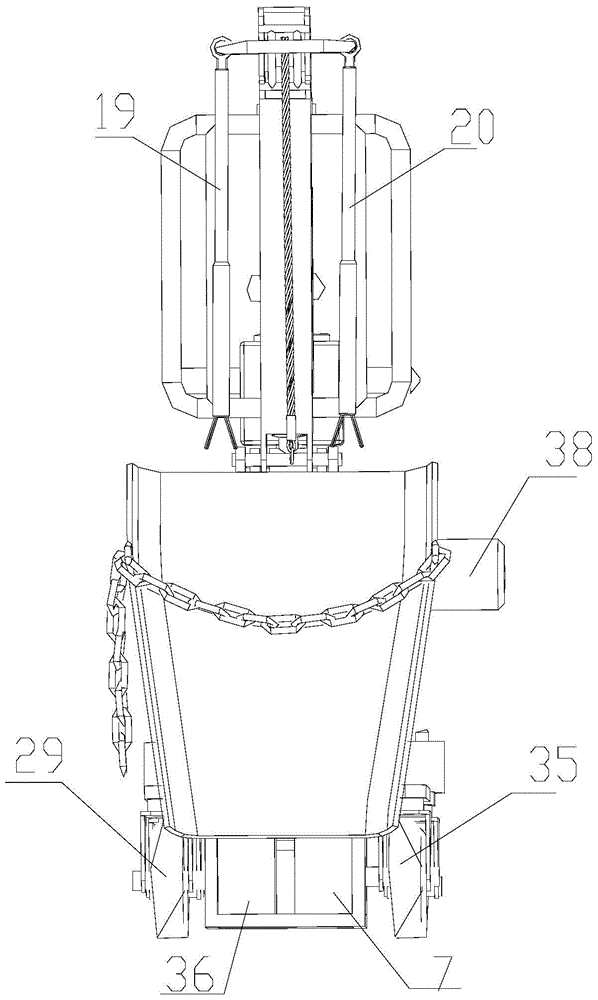

[0051] This embodiment provides a figure 1 The layout of the truck for sick and dead pigs in the pig farm shown is almost completely symmetrical. This design is considered from the perspective of reasonable counterweight and balanced force. The truck includes a frame 1, a bottom plate 2, a number of wheels, a lifting device, a driving device, a spiral bracket, a retractable support frame (19, 20), a rotating device, a multifunctional handle 8, a baffle 11, and a power box 9. And the left handle 16. The power box 9 is used to place the power supply and the main controller, and is fixed on the frame, and the left handle 16 is arranged above the power box. See Figure 4 , The handlebar is equipped with a control panel, the control panel includes a weight up button 26, a weight down button 27, a lifting motor stop button 28, a forward button 32, a stop button 33, a back button 34, a left turn button 40, a right turn Button 41.

[0052] See figure 1 , 8 In this embodiment, there are...

Embodiment 2

[0066] The structure of this embodiment is the same as that of Embodiment 1 except for the following features:

[0067] In this embodiment, the rotating device is realized by using a cross roller bearing, and its structure is shown in Figure 12 (a) and (b). The mounting holes of the inner ring and outer ring of the cross roller bearing are through holes, and the directions of the two rows of mounting holes are opposite. The outer ring of the cross roller bearing and the bottom plate 2 of the truck are fixed with hexagon bolts, and the inner ring and the frame 1 are also hexagon The bolts are fixed, and the inner ring is in interference fit with a stub shaft, and the cross roller bearing and bearing cover axially locate the stub shaft. In this way, the inner and outer rings of the cross roller bearing do not interfere with each other to realize the rotation of the truck frame. In this way, the rotating motion of the truck frame can be realized by using the characteristic that the...

Embodiment 3

[0070] The structure of this embodiment is the same as that of Embodiment 1 except for the following features:

[0071] In this embodiment, the rotating device is realized by using a slewing bearing 62. For the structure, see Figure 13 (a) and (b). The mounting holes of the inner ring and the outer ring of the slewing bearing 62 are through holes, and the two rows of mounting holes are reversed. Direction, the outer ring of the slewing support bearing 62 and the bottom plate 2 of the truck are fixed with hexagon bolts, the inner ring and the frame 1 are also fixed with hexagon bolts, and a gasket 61 is provided between the inner ring and the bottom plate of the frame. Out of the gap, easy to rotate. The bearing drive motor 64 is fixed to the carrier floor 2 by bolts, and the output shaft and the first gear 63 are connected by a key. In this way, the bearing drive motor 64 drives the first gear 63, and the first gear 63 meshes with the internal gear of the slewing support bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com