Semi-automatic lamp inspection platform for capsules

A semi-automatic, light inspection table technology, applied in sorting and other directions, can solve problems such as affecting work efficiency, capsule pollution, missed selection, etc., and achieve the effects of high feeding reliability, comfort, and ease of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

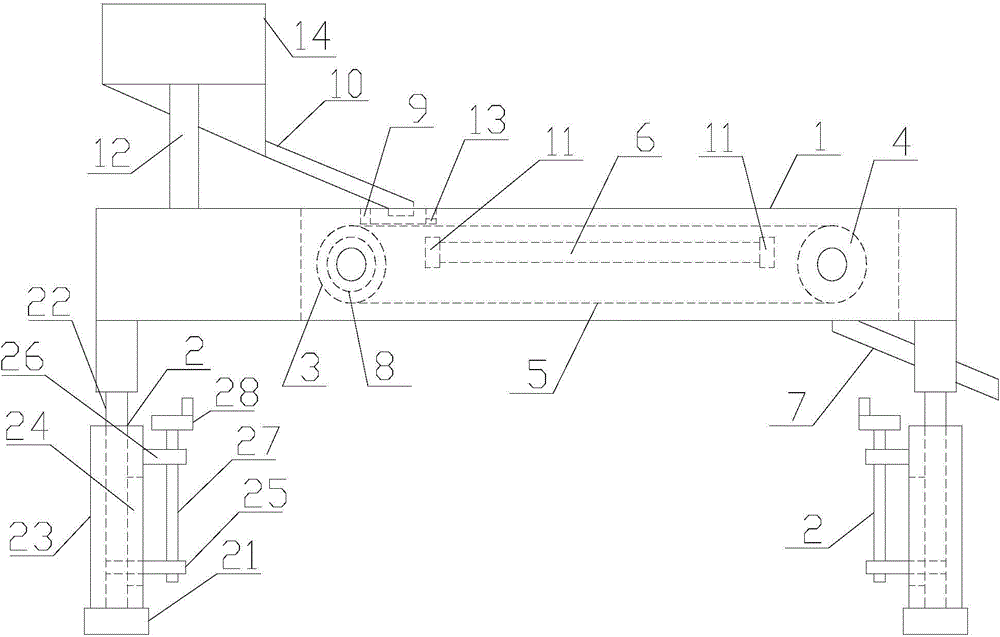

[0016] refer to figure 1 , a semi-automatic light inspection platform for capsules of the present invention, comprising a frame 1, a lifting mechanism 2, a driving roller 3, a driven roller 4, a conveyor belt 5, a lighting lamp 6, a chute 7, a frame body 9, and a feeding pipe 10 and a hopper 14, the rectangular cavity of the frame 1 is provided with a driving roller 3, a driven roller 4, a lighting lamp 6 and a frame body 9, the driving roller 3 is connected with a motor 8, and the driving roller 3 And the driven roller 4 is covered with a conveyor belt 5, the lighting lamp 6 is arranged below the upper belt body of the conveyor belt 5, and the frame 9 is arranged directly above the front portion of the conveyor belt 5, and the frame 9 The lower end of the rear frame is provided with a gap 13 for capsule output, the frame 1 is provided with a chute 7 below the driven roller 4, the front end of the frame 1 is provided with a hopper 14, and the feeding The input end of pipe 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com