Thread guide unit for textile machine

A textile machine and yarn guide technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of expensive, increased installation and maintenance costs of yarn guide units, etc., to reduce inertia and benefit Installation and maintenance costs, effects of improved controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

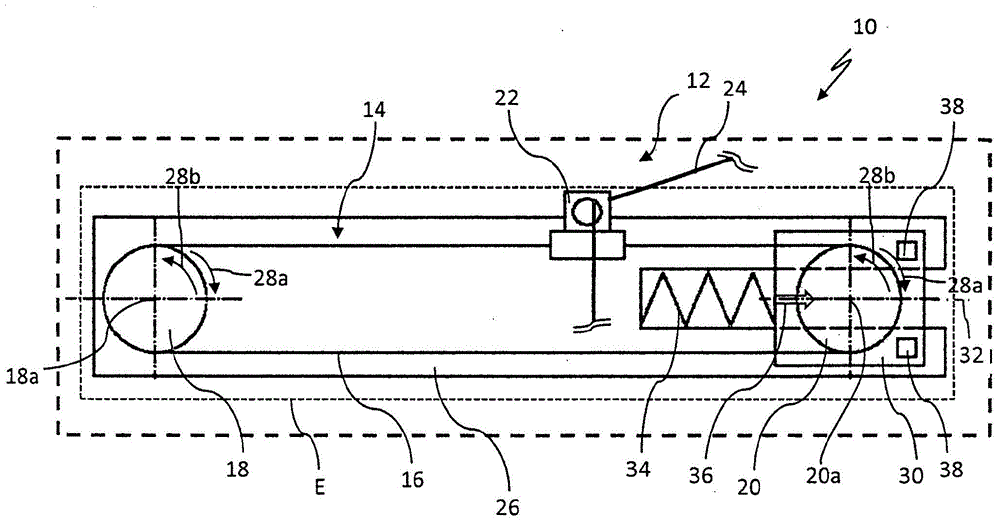

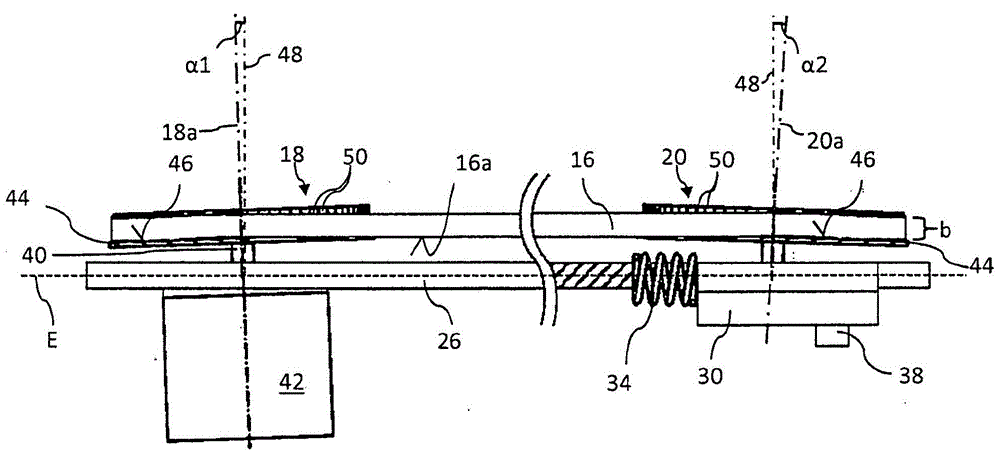

[0026] figure 1 A textile machine 10 is shown with a thread guide unit 12 . The textile machine 10 is only shown schematically for reasons of graphic representation and can be designed, for example, as a winder or texturing machine. The thread guide unit 12 has a belt drive 14 with a drive belt 16 which is wound around a first pulley 18 and a second pulley 20 . The drive belt 16 is currently implemented as a continuous belt. Drive belt 16 forms a belt with its two return sections figure 1 The belt plane indicated by the dotted line in , which is indicated by the reference character "E". A yarn guide 22 for guiding a yarn 24 is fixed on the drive belt 16 . The two belt pulleys 18 , 20 are mounted rotatably about their respective axes of rotation 18 a , 20 a relative to the support element 26 of the thread guide unit 12 in mutually opposite directions of rotation 28 a , 28 b. The carrier element 26 is in the present case embodied, for example, as a carrier plate. The first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com