an optical film

An optical thin film and optical film technology, applied in the field of optical materials, can solve problems such as complex manufacturing process, many factors affecting product quality, thin production, and difficult quality control of high-flatness TAC film products, so as to improve flatness and realize Thin production and the effect of improving production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

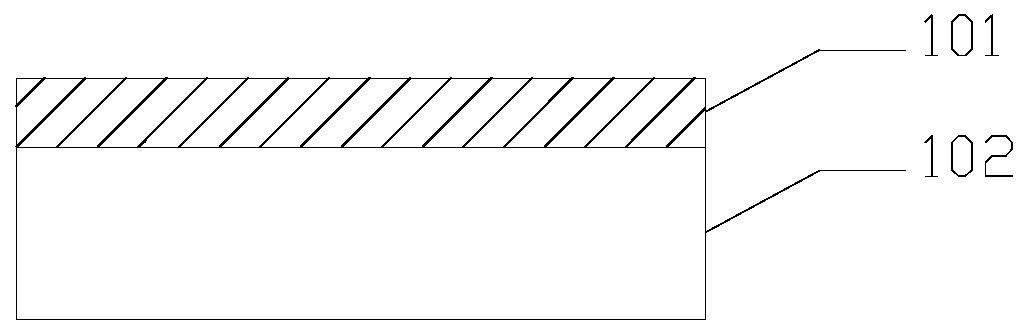

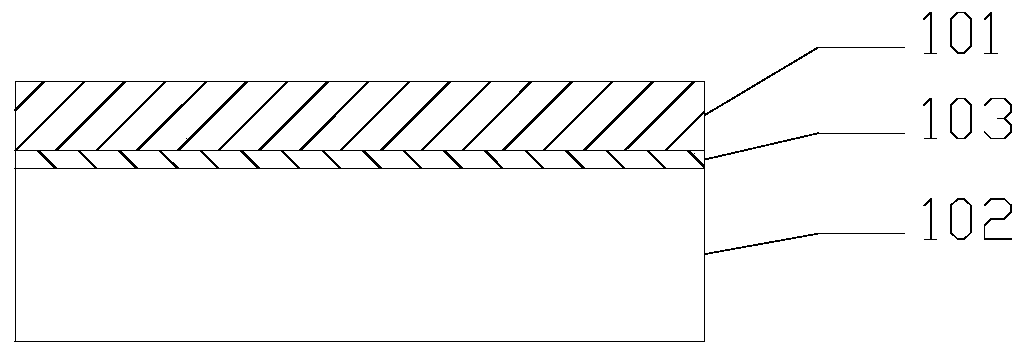

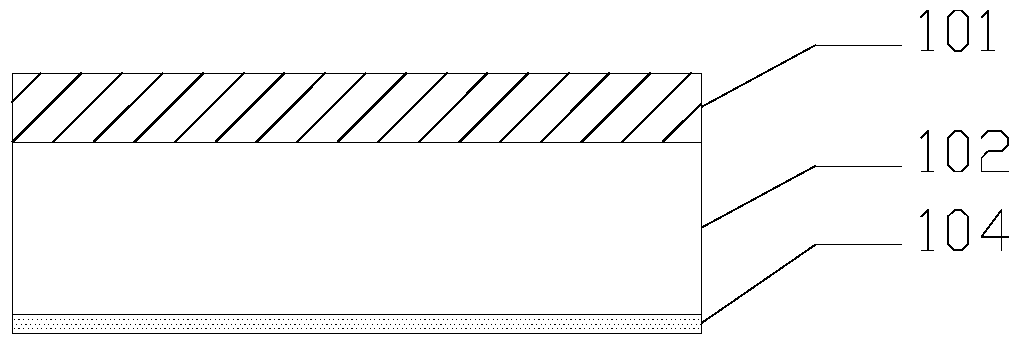

[0026] Such as figure 1 As shown, the optical film includes a PET layer (102), the PET layer is a PET optical film, and a TAC layer (101) is coated or cast on the upper surface of the PET film.

[0027] First configure TAC liquid: mix the materials in the following table according to the weight ratio.

[0028] material

[0029] The above-mentioned TAC liquid is uniformly distributed through extrusion coating, knife coating, bar coating, roll coating, transfer coating, curtain coating, spray coating or casting, etc. The surface of the PET film is dried and formed into a film to become a product.

[0030] The prepared products are tested, and the test results are as follows:

[0031] Test items

[0032] TAC film thickness

Embodiment 2

[0034] Such as figure 1 As shown, the optical film includes a PET layer (102), the PET layer is a PET optical film, and a TAC layer (101) is coated or cast on the upper surface of the PET film.

[0035] First configure TAC liquid: mix the materials in the following table according to the weight ratio.

[0036] material

Ratio

TAC

100

800

43

10

2

[0037] The above-mentioned TAC liquid is uniformly distributed through extrusion coating, knife coating, bar coating, roll coating, transfer coating, curtain coating, spray coating or casting, etc. The surface of the PET film is dried and formed into a film to become a product.

[0038] The prepared products are tested, and the test results are as follows:

[0039] Test items

Embodiment 3

[0041] Such as figure 1 As shown, the optical film includes a PET layer (102), the PET layer is a PET optical film, and a TAC layer (101) is coated or cast on the upper surface of the PET film.

[0042] First configure TAC liquid: mix the materials in the following table according to the weight ratio.

[0043] material

Ratio

TAC

100

800

43

10

[0044] High refractive agent

5

[0045] The above-mentioned TAC liquid is uniformly distributed through extrusion coating, knife coating, bar coating, roll coating, transfer coating, curtain coating, spray coating or casting, etc. The surface of the PET film is dried and formed into a film to become a product.

[0046] The prepared products are tested, and the test results are as follows:

[0047] Test items

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com