An ultrasonic phased array automatic flaw detection machine for railway vehicle axles

A technology for railway vehicles and phased array probes, which is applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, can solve the problems of low detection efficiency and accuracy, labor-intensive operators, and inability to adapt to railway vehicles, etc., to achieve detection efficiency and high accuracy, improve maintenance quality, and reduce the effect of wheel and axle maintenance process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

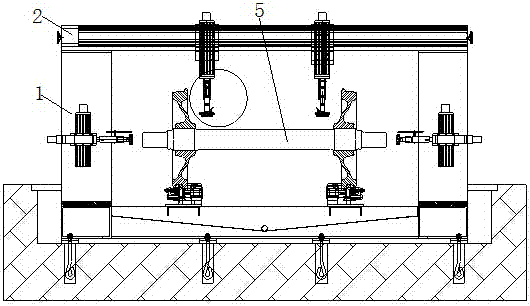

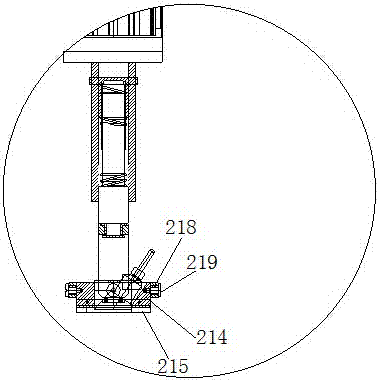

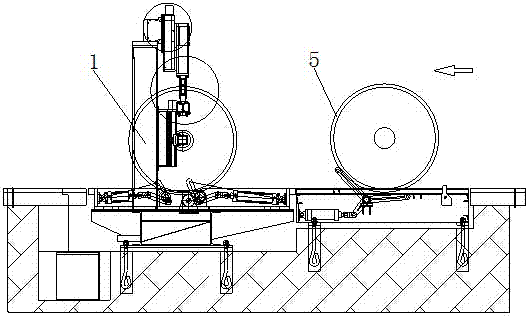

[0028] as attached Figure 1-10An ultrasonic phased array automatic flaw detection machine for a railway vehicle wheel axle shown in the present invention includes a bed body 1, a module beam 2, a follower device, a centering device, an A-type probe 3, and a phased array probe 4 , a wheel shaft rotation mechanism, a loading and unloading mechanism, and a phased array ultrasonic flaw detector located on the bed body 1; a module beam 2 is provided above the bed body 1; Two relative follow-up devices; the follow-up devices are located at the two ends of the inner side of the wheel shaft to be measured; the phased array probe 4 is arranged below the follow-up device, and can move circumferentially through the follow-up device; the There are centering devices on both sides of the bed body 1 that can move up and down; the A-type probe 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com