Boiler hot primary air pipe hanger layout structure

A technology for pipe hangers and layout structures, which is applied in the directions of pipe supports, pipes/pipe joints/pipes, mechanical equipment, etc. The effect of uniform force, eliminating blind plate force and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

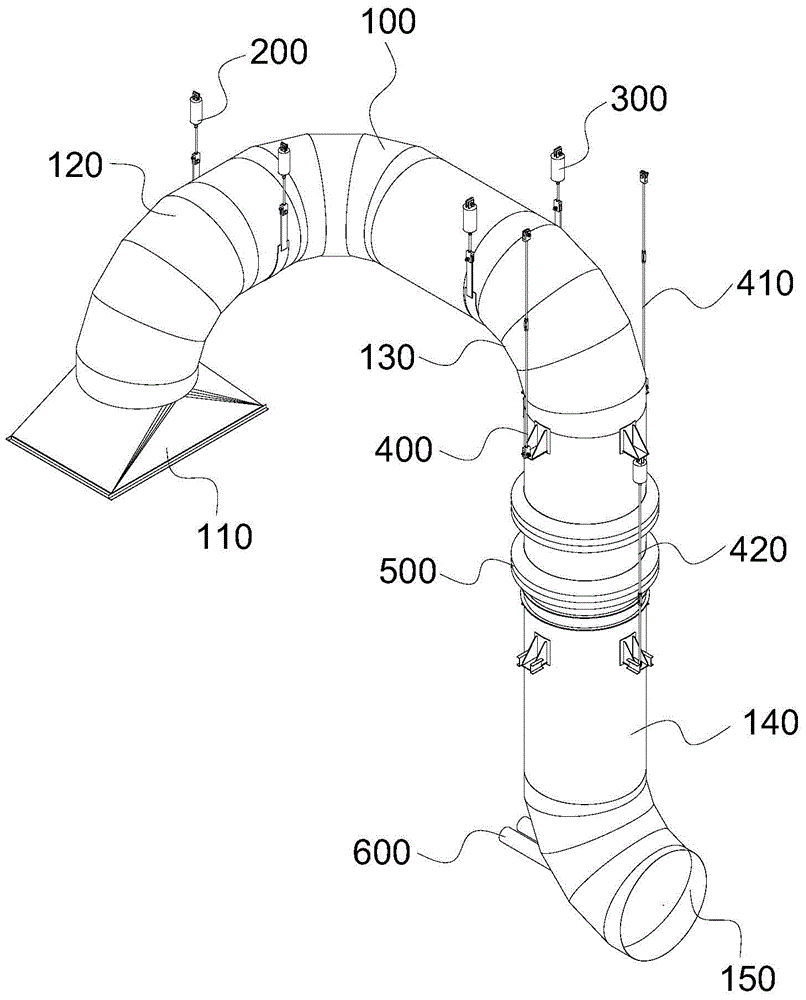

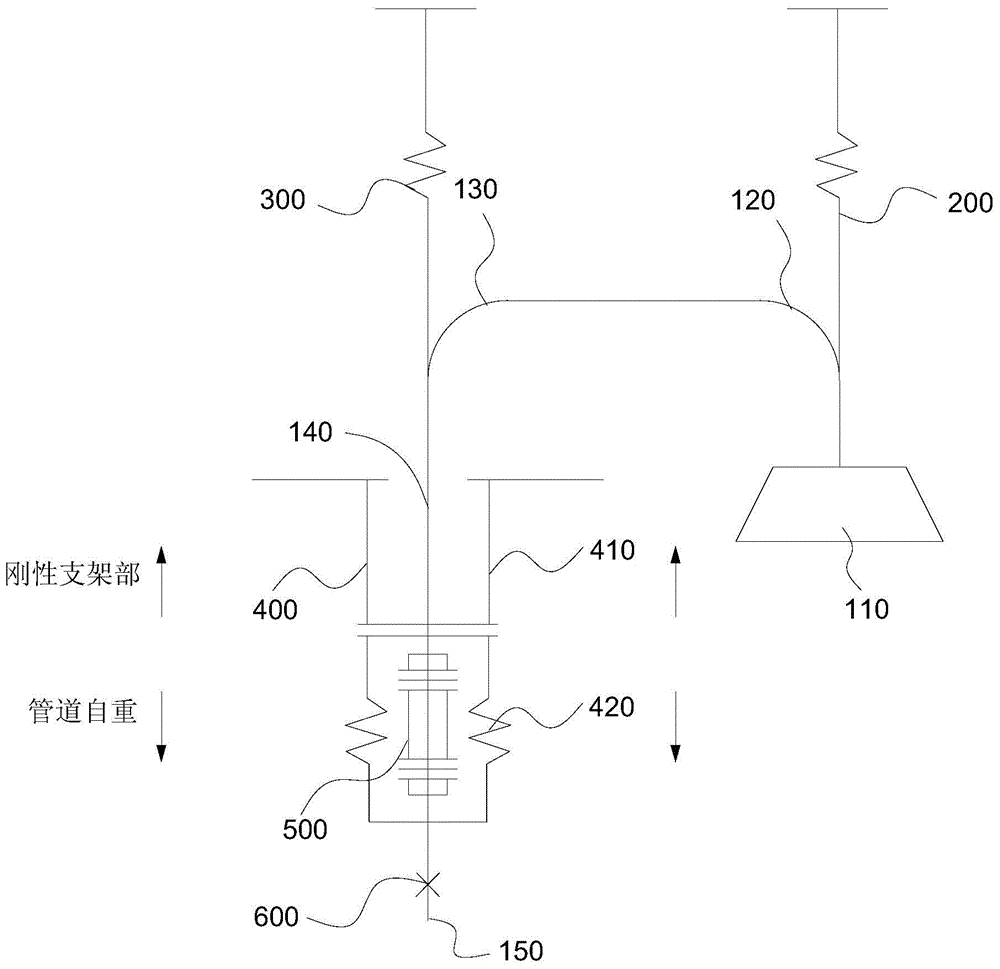

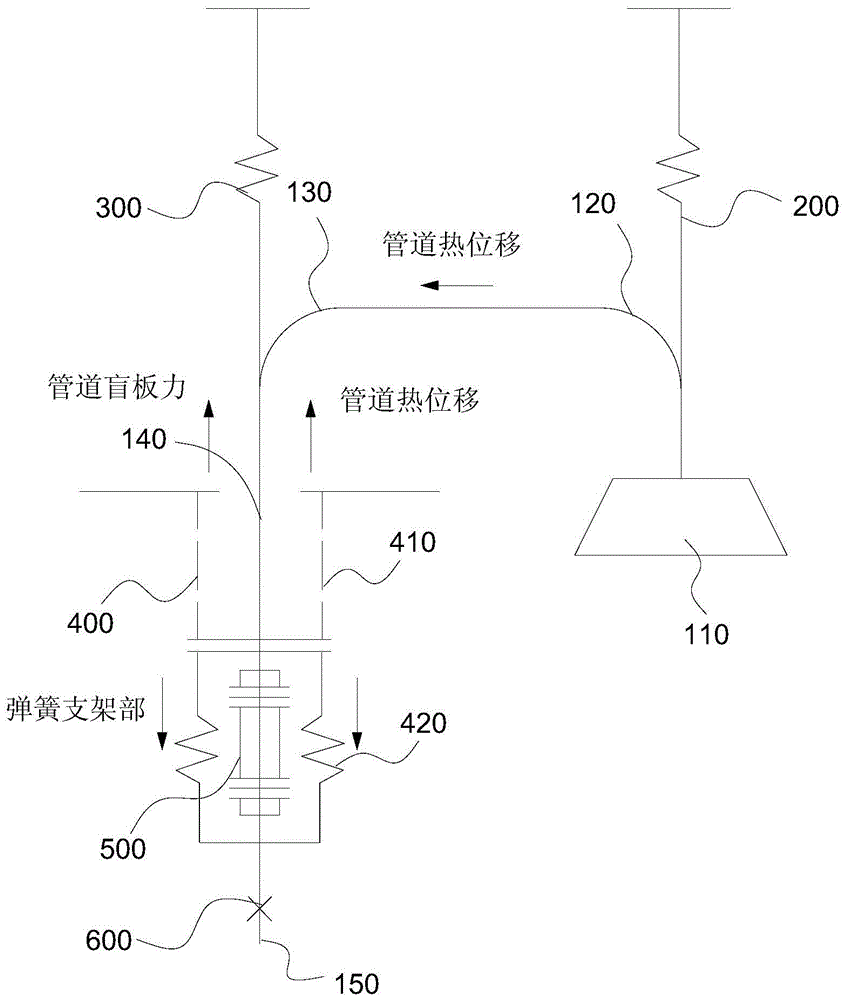

[0023] like figure 1 As shown, a boiler hot primary air pipe hanger layout structure includes a hot primary air pipe 100 and a support frame (not shown in the figure). The hot primary air pipeline 100 includes an air preheater hot primary air interface 110 , a pipeline elbow section, a pipeline vertical section 140 and a pipeline outlet 150 arranged in sequence. The pipe elbow section is provided with an elastic hanger, and the vertical section of the pipe is provided with a three-dimensional compensator 500 and a combined hanger 400, and the elastic hanger and the combined hanger 400 are both connected to the support frame.

[0024] The compensator is canceled at the hot primary air interface 110 of the air preheater, and the air preheater hot primary air interface 110 transitions to the circular hot primary air pipe part through the square and round...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com