Zinc-alloy squirrel-cage type motor flange spring buffer washing cylinder

A technology of spring buffering and motor flange, which is applied to washing devices, asynchronous induction motors, electromechanical devices, etc., can solve the problems of increasing the size of the bottom of the outer casing, increasing the sealing performance of the motor shaft, and increasing the diameter of the motor shaft. Amount of wear, good cushioning effect, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments:

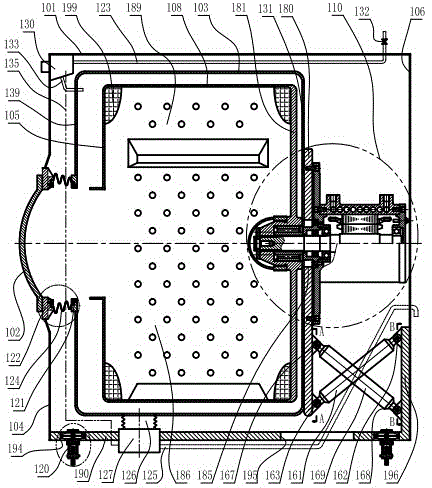

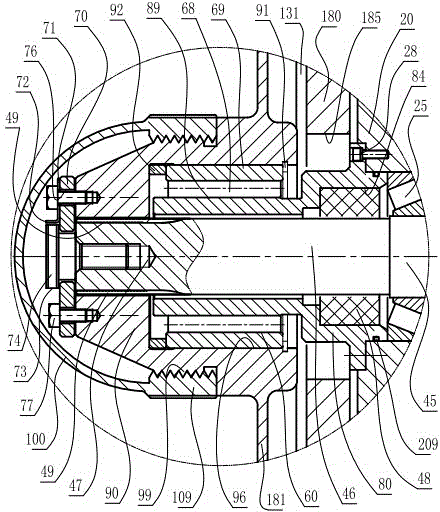

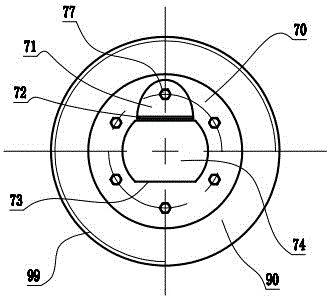

[0040] figure 1 and Figure 7 Middle: Zinc alloy squirrel cage motor flange spring buffer washing drum, including: outer shell 101, drum door 102, water tub 103, rolling drum 108, upright plate 180, base plate 190, squirrel cage water-cooled motor assembly 110 As well as the external water supply pipe 123 and the outer drainage pipe 125, the outer casing 101 is provided with a regulating and operating box 130 on the upper part of the front, and the inner end of the external water supply pipe 123 is connected to the regulating and operating box 130, and the external water supply The outer end of the pipe 123 is connected to the water inlet valve 132 , the outer water supply pipe 123 is connected to the inner anti-vibration water inlet pipe 133 after passing through the regulating operation box 130 , and the outlet of the inner anti-vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com