Automatic welding and tape adhering integral machine for car plate

A technology for automatic welding and car signage, applied in other manufacturing equipment/tools, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

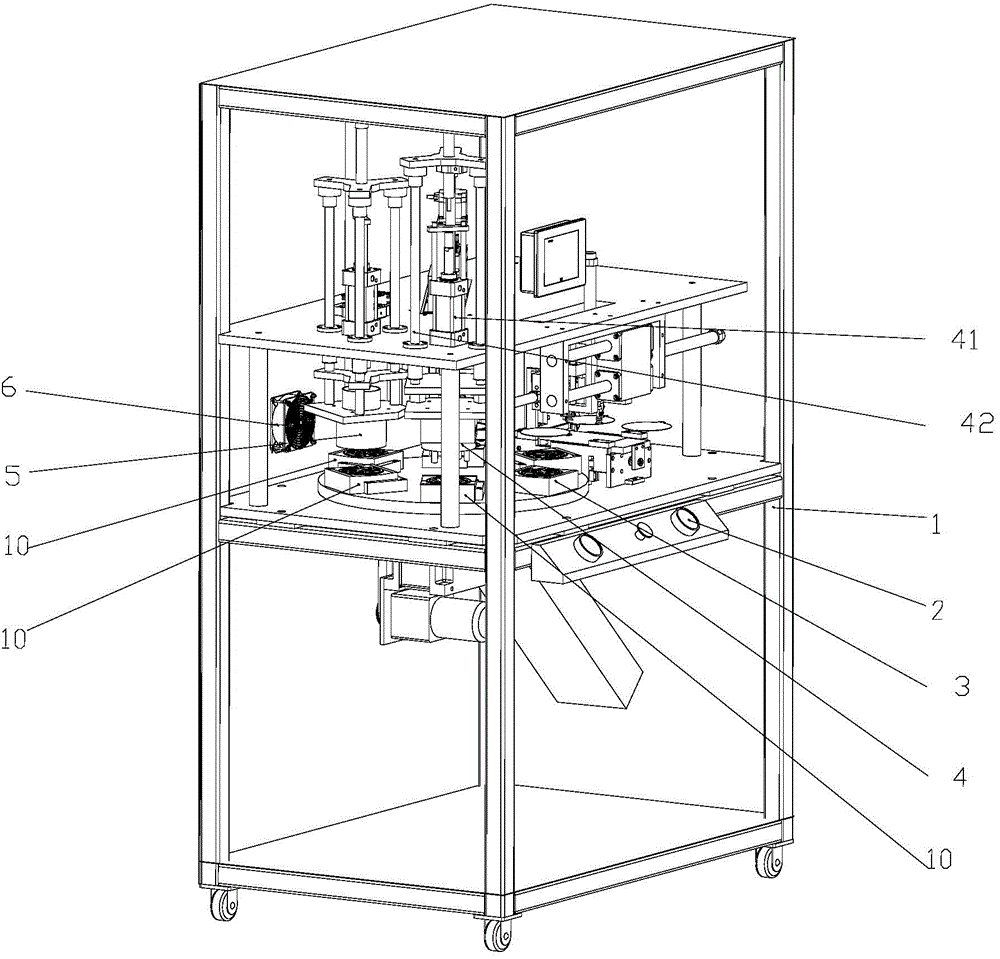

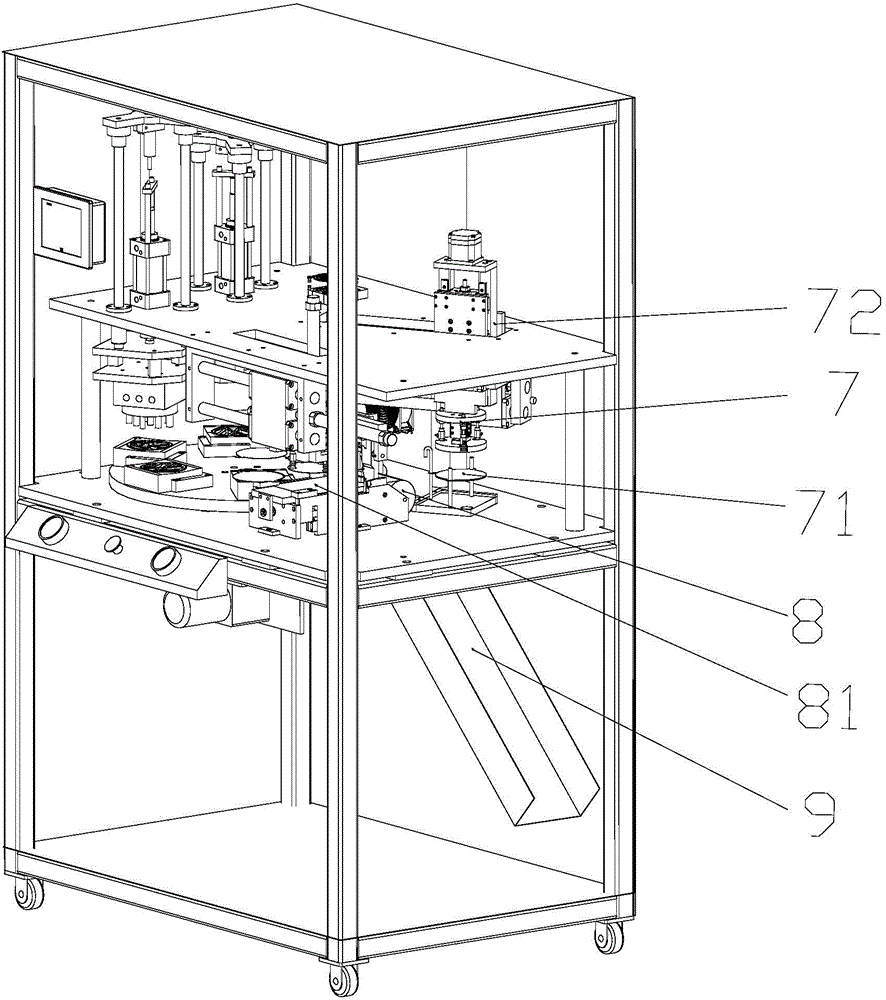

[0048] refer to Figure 1 to Figure 11 , an automatic welding and tape-attaching machine for automobile signs, including a frame 1 and an indexable assembly workbench 2 arranged on the frame 1, the workbench 2 is provided with a turntable, and the turntable is connected to a step-rotating mechanism, the first station 3 for feeding, the second station 4 for welding, the third station 5 for priming, and the fourth station for drying are sequentially arranged on the turntable. Station 6, the fifth station 7 for sticking tape, the sixth station 8 for sticking protective film and unloading finished products, and each of the stations corresponding to the workbench is equipped with a The positioning base 10, each of the above-mentioned stations are controlled by a controller.

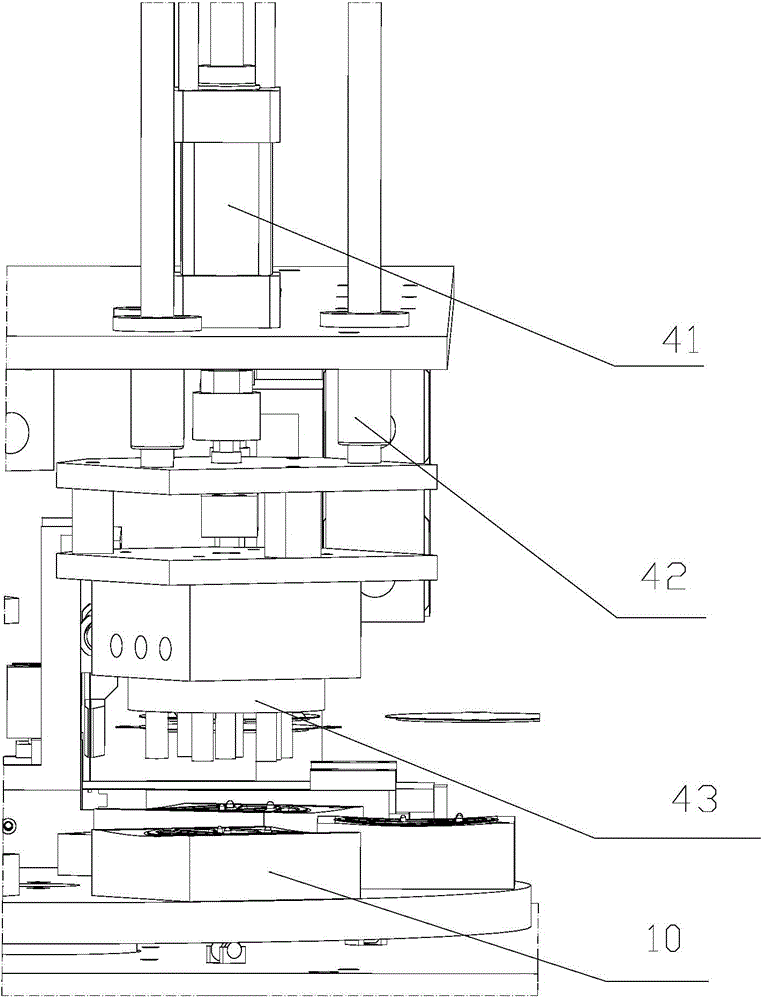

[0049] The second station 4 includes a first lifting cylinder 41, a welding head and a heating device 43, the piston rod of the first lifting cylinder 41 is connected to the heating device, and the lower end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com