A super-stabilization treatment method for in-situ crystallization catalyst with high rare earth content

A technology with high rare earth content and in-situ crystallization, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

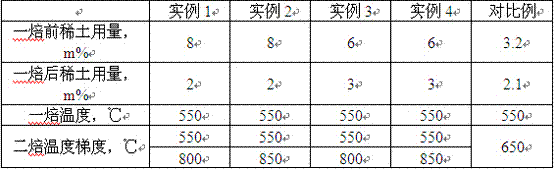

example 1

[0034] (1) Ammonium exchange

[0035]Add 1200g of deionized water to the stainless steel kettle, add 300g of in-situ crystallization NaY catalyst and 90g of ammonium chloride under stirring conditions, adjust the pH value to 3.0-4.0 with 4% dilute hydrochloric acid solution, and exchange at 80°C for 40 minutes , filtered, and the filter cake was rinsed with deionized water, and exchanged again in the same way to obtain Na 2 NH with O content below 4.0m% 4 Y-type catalyst.

[0036] (2) Rare earth exchange

[0037] Add 1200g of deionized water to the above product, add RECl 3 Rare earth (RE 2 o 3 8% of the weight of the catalyst) solution, at a pH of 3.0-4.0, exchanged for 40 minutes at 80°C to obtain REY and NH 4 Type Y catalyst mixture.

[0038] (3) Once roasted

[0039] The above mixture was hydrothermally calcined at 550° C. for 4 hours.

[0040] (4) Rare earth supplementation for materials after first roasting

[0041] Add 1200g of deionized water and 60g of ammon...

example 2

[0047] According to the method of Example 1, the in-situ crystallized NaY type product is subjected to ultra-stabilization modification treatment: wherein the step (5) roasting temperature gradient is: the filter cake is roasted at 550°C for 2 hours, and then heated to 850°C and then roasted for 2 hours. Other conditions are the same as example 1 to obtain catalyst A2.

example 3

[0049] (1) Ammonium exchange

[0050] Add 1200g of deionized water to the stainless steel kettle, add 300g of in-situ crystallization NaY catalyst and 90g of ammonium chloride under stirring conditions, adjust the pH value to 3.0-4.0 with 4% dilute hydrochloric acid solution, and exchange at 80°C for 40 minutes , filtered, and the filter cake was rinsed with deionized water, and exchanged again in the same way to obtain Na 2 NH with O content below 4.0m% 4 Y-type catalyst.

[0051] (2) Rare earth exchange

[0052] Add 1200g of deionized water to the above product, add RECl 3 Rare earth (RE 2 o 3 6% by weight of the catalyst) solution, exchanged for 40 minutes at pH 3.0-4.0, 80°C, to obtain REY type and NH 4 Type Y catalyst mixture.

[0053] (3) Once roasted

[0054] The above mixture was fired at 550°C for 4 hours.

[0055] (4) After the first baking, the material is supplemented with rare earth

[0056] Add 1200g of deionized water and 60g of ammonium chloride to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com