Small-caliber rimfire cartridge magazine

A technology of small-caliber bullets, applied in ammunition supply, weapon accessories, offensive equipment, etc., can solve the problems affecting the supply of ammunition and shooting accuracy, the impact of the edge of the bullet, the impact of the primer, and the existence of safety hazards, etc., to eliminate safety hazards and avoid external forces Squeeze, reduce friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

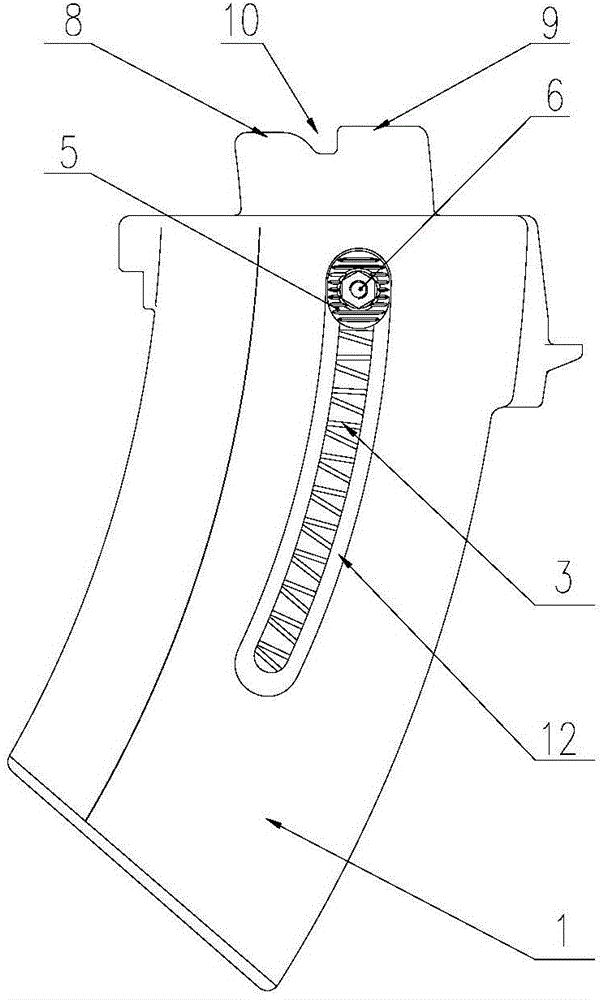

[0029] see Figure 1 to Figure 4 , is a preferred embodiment of the small-caliber rimfire magazine, comprising a magazine body 1, the upper end of the magazine body 1 is provided with a bullet port 9, and the lower end of the magazine body 1 is provided with a magazine bottom Cover 7, the magazine of the magazine body 1 is provided with a support spring 2, and a support spring 3 is provided between the support spring 2 and the magazine bottom cover 7. Under normal conditions, the support spring 2 is located at the Right below the bullet port 9, a guide shaft 4 is inserted horizontally on the spring support plate 2, and the spring support plate 2 can rotate along the axis of the guide shaft 4. In this embodiment, the spring support plate 2 and the guide shaft 4 clearance fit. The two ends of the guide shaft 4 are respectively inserted into the guide chute 12 symmetrically provided on the left side wall and the right side wall of the magazine body 1, and the guide shaft 4 can s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com