Double-layer rotary sieve

A rotary screen, double-layer technology, applied in the field of sieves, can solve the problems of poor screening effect, single use, backward structure, etc., and achieve the effects of improving screening efficiency, prolonging screening time, and increasing screening area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

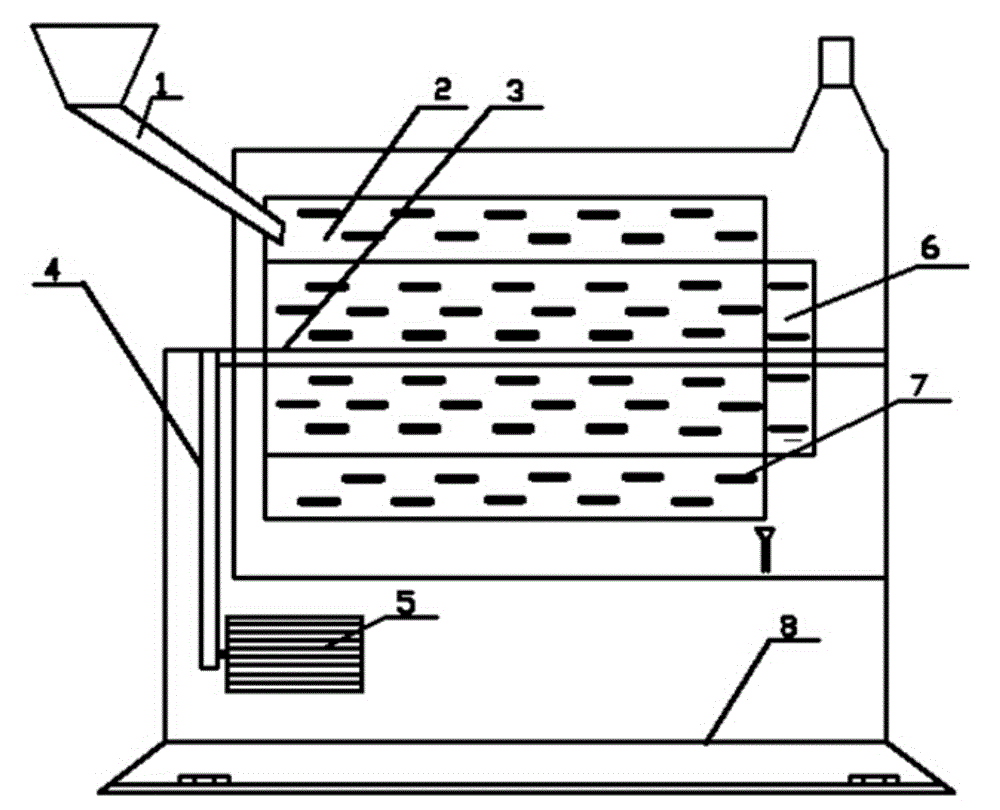

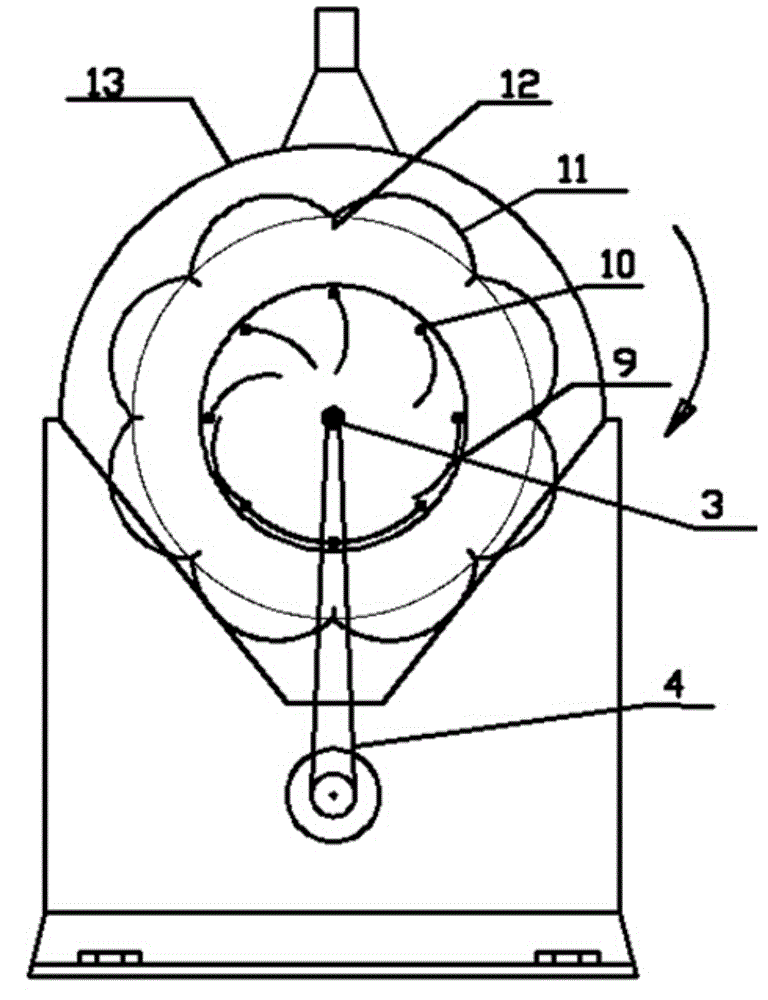

[0016] A double-layer rotary screen, fixed on the support base 8, including a casing 12, an outer sieve 2 and an inner sieve 6, the inner sieve 6 is arranged on the inner layer of the outer sieve 2, the outer sieve 2 is arranged on the outside of the outer sieve 2, the outer sieve 2 and the The inner sieve 6 is provided with a screen hole 7, and the outer shell 12 is provided with a feed port 1. The interior of the inner sieve 6 is provided with a number of arc-shaped lining plates 9, and the arc-shaped lining plates 9 are close to the inner sieve 6. Two adjacent The arc-shaped liners 9 connect end to end to form a cylinder; one end of each arc-shaped liner 9 is connected to the inner wall of the inner screen 6 through a hinge 10 . The outer sieve 2 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com