Wire reeling device for electrocardiogram machine

A wire winding device, electrocardiogram machine technology, applied in medical science, sensors, diagnostic recording/measurement, etc., can solve the problems of shortened wire life, looseness, inconvenient use, etc., and achieve long wire life, convenient operation, and coil line order effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

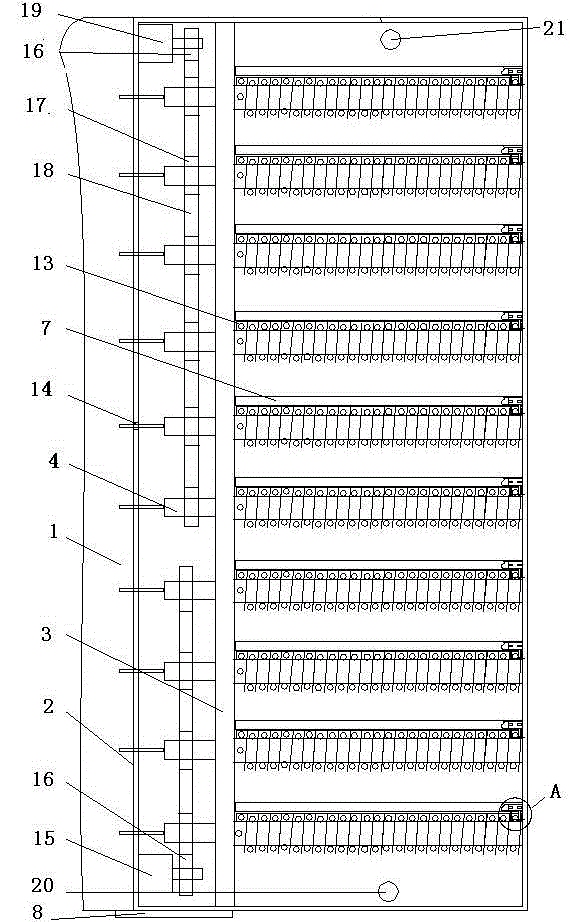

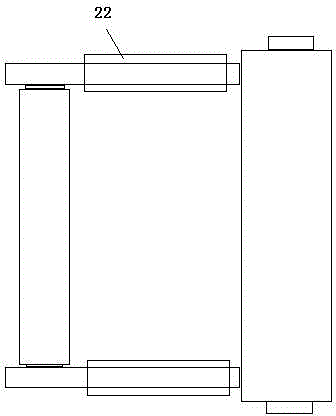

[0015] As shown in the accompanying drawings, a wire winding device for an electrocardiogram machine is provided with a casing 1, which is characterized in that a winding casing 2 is provided at the outlet end on the side of the casing 1, and a bracket 3 is arranged inside the winding casing 2. , rotating shaft 4, inner bearing seat, outer bearing seat, slideway 7, control device 8, thread guide 6 and transmission device, and described thread guide is made up of slide plate 9, roller shaft 10, strut 11 and pulley 12, The left and right ends of one side of the slide plate 9 are respectively provided with roller shafts 10, and the upper and lower ends are respectively provided with pulleys 12. The bottom surface is provided with ten parallel rectangular guide grooves 13, and the side is provided with ten threading holes 14. One side of the guide grooves 13 is provided with a rotating shaft 10, and the other side is provided with a slideway 7 along the line. The guide grooves 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com