Plant cultivation device

A cultivation device and plant technology, applied in the field of plant cultivation, can solve the problems of increasing the difficulty of removal and the difficulty of effectively removing the heat of the light source, and achieve the effect of strengthening the heat dissipation effect of the air flow, large cultivation density, and high light source space efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

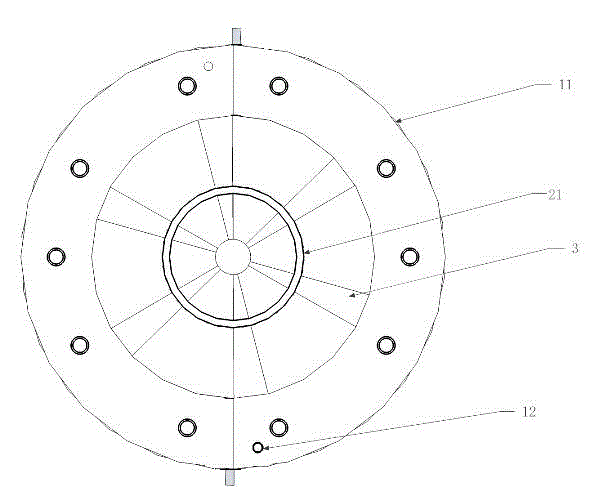

[0025] Figure 1 to Figure 3 A first embodiment of a cultivation device is illustrated. The cylindrical plant cultivation frame 1 of this cultivation device is made up of 6 layers of circular cultivation grooves 11, and the cultivation grooves 11 are connected by firm brackets. the height of the plant. Cultivation substrate can be filled in the cultivation tank 11, and plants can also be cultivated with pure nutrient solution without filling the cultivation substrate, but in any case, the water overflowed by the upper cultivation tank will be led to the lower cultivation tank by the water pipe 12 between the upper and lower cultivation tanks, and the water pipe 12 The upper end of the nozzle should be lower than the cultivation surface of the cultivation groove 11 to control the depth of water in the groove.

[0026] The cultivation device has a cylindrical light source 2 for providing illumination to the cultivated crops. The light source 2 is vertically arranged at the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com