Arc Heated Plasma Torch

A plasma and arc heating technology, applied in the direction of plasma, electrical components, etc., can solve the problems of complex electrode replacement, low cooling efficiency, and easy ablation of electrodes, and achieve simplified water cooling system, improved cooling efficiency, and improved cooling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

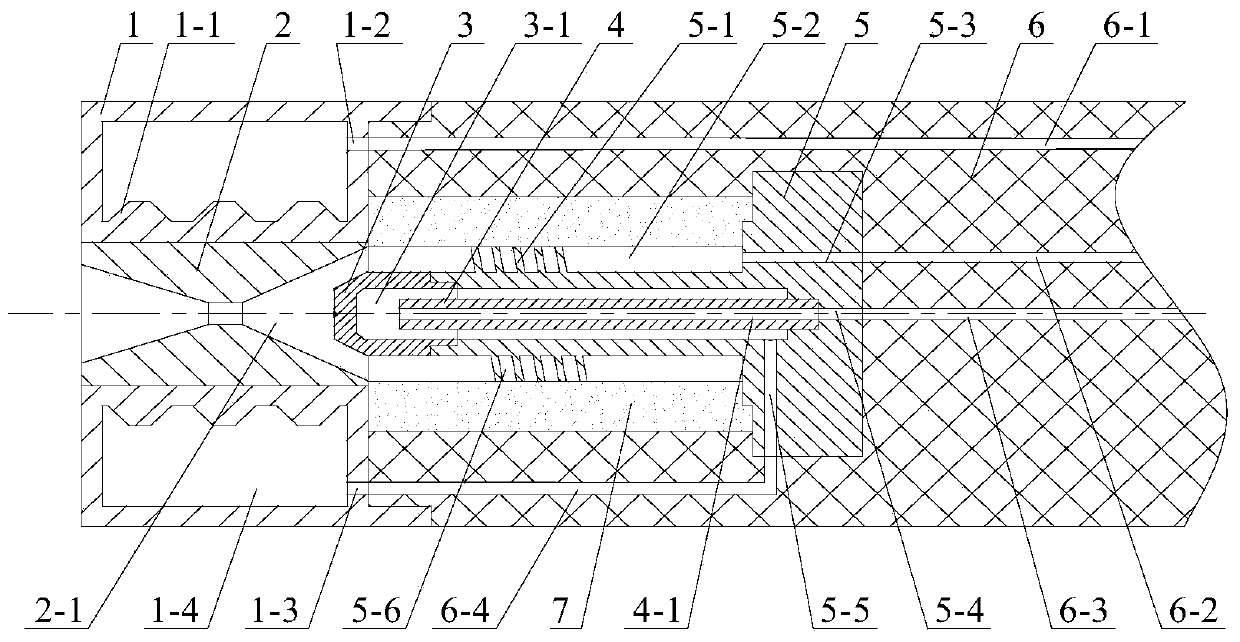

[0015] combine figure 1 :

[0016] An arc heating plasma spray gun of the present invention comprises an anode seat 1, a replaceable anode nozzle 2, a cathode head 3, a conductive gun core 5, a gun body 6 and an insulating sleeve 7, and the insulating sleeve 7 is set on the conductive gun core 5 , the cathode head 3 is fixedly connected with the conductive gun core 5 to form the cathode body, the gun body 6 is formed by pouring resin material on the periphery of the insulating sleeve 7 and the conductive gun core 5, the anode seat 1 is fixedly connected with the gun body 6, and the anode nozzle can be replaced 2. It is fixed on the inner wall of the anode seat 1 to form the anode body. The conductive gun core 5 is provided with a conductive gun core air inlet 5-3 communicated with the gun body air flow channel 6-2 on the gun body 6. The conductive gun core air inlet 5 -3 communicates with the cavity 5-2 between the insulating sleeve 7 and the conductive gun core 5, and a spir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com