Online adjustable closing force gas lubricating mechanical sealing device

A mechanical sealing device and gas lubrication technology, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of excessive leakage, excessive thickness of end film, contact friction and wear, etc., to avoid direct contact friction and wear, Effects of improving service life and reliability and reducing seal closing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

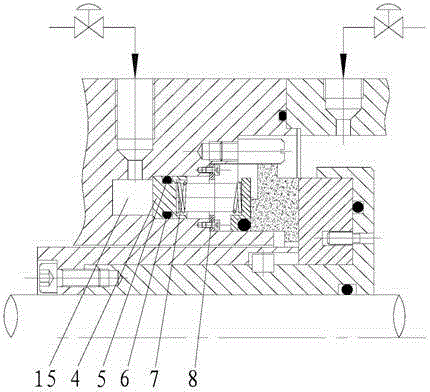

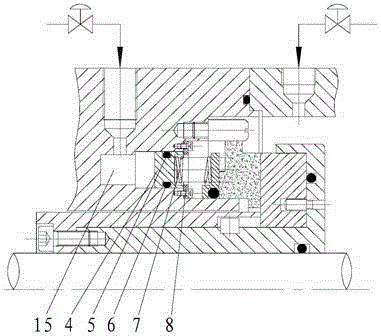

[0032] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 :

[0033]A gas lubricated mechanical seal device with online adjustable closing force, comprising a moving ring axial positioning ring 1, a sealing end cover 2, a moving ring seat 3, a piston 4, a working spring 7, a piston limit ring 8, a push ring 9, The static ring 10, the moving ring 11 and the sealing cavity 12, the moving ring 11 is fixed on the moving ring seat 3 and rotates with the shaft, the static ring 10 is installed on the sealing end cover 2; the sealing end cover 2 A piston chamber 15 is provided inside; an external gas supply channel 14 is opened on the sealing end cover 2, and communicates with the piston chamber 15 on one side of the piston 4; a working spring is provided between the other side of the piston 4 and the static ring 10 7. The piston 4 moves axially along the piston cavity 15 to change the compression amount of the working spring 7;

[0034] The compression amount of...

Embodiment 2

[0044] refer to figure 1 , 2 , 3, 4, 6, the difference between this embodiment and the first embodiment is that the working spring 7 is a large spring, and the rest of the structure and implementation are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com