Axial-flow compressor stator blade system with adjustable first and second half of segments and working method thereof

A technology for axial flow compressors and stator blades, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as increased losses, and achieve the effects of easy engineering implementation and simple adjustment mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

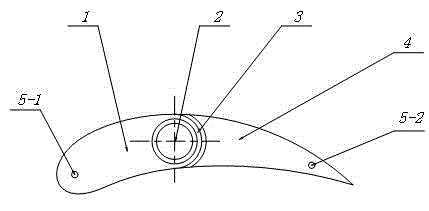

[0019] The following combination Figure 1 to Figure 5 The implementation method of the front and rear half adjustable stator blades of the present invention is illustrated. The combination of the front and rear halves of the stator blade constitutes the overall stator blade, which is designed according to the conventional design method, that is, according to the distribution of the inlet and outlet airflow angles of the stator blade along the blade height at the design point, several two-dimensional blade shapes are designed along the blade height direction, and then along the blade height Gao stacked these two-dimensional blade shapes to form three-dimensional blades. According to the three-dimensional blade shape designed above, select the outer diameter of the connecting cylinder 2 and the position of the blade (near the maximum thickness of the blade); and then divide the blade into the first half blade 1 and the second half blade 4 . When the first half of the blade 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com