Connection structure of tool bit and host of hair scissors

A connection structure and hair clipper technology, applied in metal processing and other directions, can solve the problems of poor safety, easily damaged parts of the cutter head, damaged components, etc., to avoid the loss of the cutter head, facilitate docking and fixation, and avoid being damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

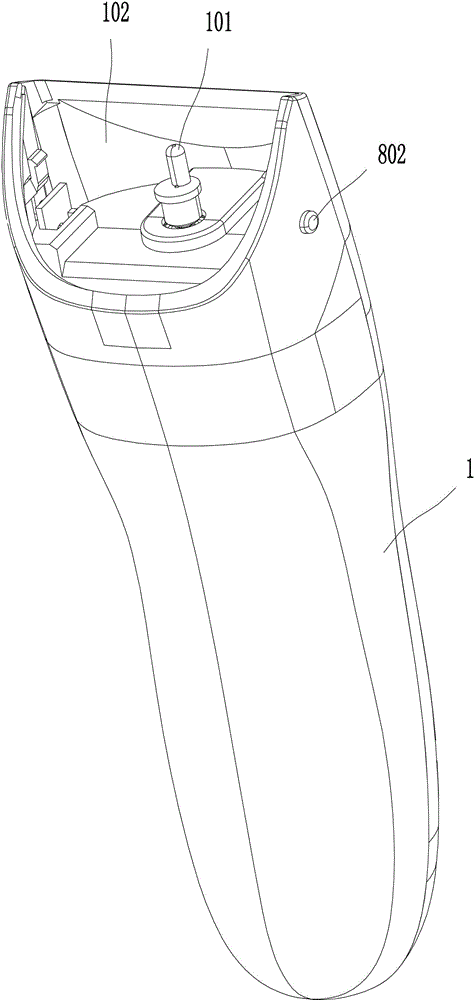

[0035] refer to Figure 1-15 Shown, the connecting structure of the cutter head of the barber scissors of the present invention and main frame, it comprises main frame 1 and cutter head 2, and main frame 1 comprises drive shaft 101, and drive shaft 101 is driven by motor, and cutter head 2 comprises movable blade 302, movable knife rest 3. The static blade 401 and the static blade holder 4, the static blade 401 is fixedly connected to the static blade holder 4, the moving blade 302 is fixedly connected to the moving blade holder 3, and the moving blade holder 3 and the moving blade 302 are installed on the static blade holder 4 , the movable blade 302 is stacked on the top of the static blade 401, and the movable blade 302 is provided with a knife pressing plate, and a torsion spring is installed on the static knife holder 4, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com