Automatic wok tossing system

A technology for automatic cooking utensils, which is applied to cooking utensils, household utensils, applications, etc., can solve the problems of small range of activities, large installation space, and waste of heat, so as to avoid waste of heat, reduce the volume of equipment, and avoid waste of fuel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

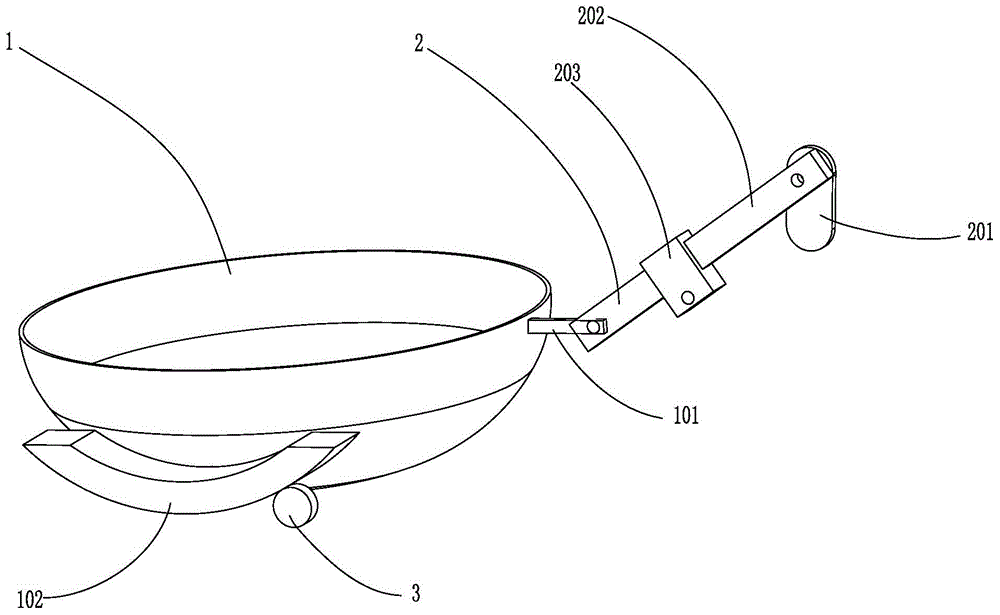

[0057] Such as figure 1 As shown, the automatic pan turning system of this embodiment includes a pan dragging type pan moving device and a pushing tool (not shown in the figure).

[0058] Wherein, the moving device for dragging a pot includes a pot 1, a pot driving device 2, and a pot supporting block (roller 3).

[0059] The pot driving device 2 is a crank rocker mechanism, which includes a crank 201, a connecting rod 202, and a rocker 203; the crank 201 is driven by a power device; the rocker 203 is provided with a hole; the connecting rod 202 passes through the hole on the rocker 203 , the head end of the connecting rod 202 is hinged with the crank 201 , and the end of the connecting rod 202 is hinged with the handle 101 of the pot 1 . There is one pan driving device, which is located at the rear side (or front side) of the pan, and the connecting rod is connected to the rear end (or front end) of the pan.

[0060] Two arc-shaped guide rails 102 are arranged symmetrically...

Embodiment 2

[0065] The difference between this embodiment and Embodiment 1 is that the pot further includes a holding mechanism, the holding mechanism includes a ring-shaped body for inserting the pot into it, and the pot end of the connecting rod is fixedly connected with the ring-shaped body .

Embodiment 3

[0067] The difference between this embodiment and Embodiment 1 is that the driving device of the pushing tool is a double crank mechanism, which includes a driving crank, a driven crank, and a connecting rod between the two; The end is connected to the driven crank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com