Automatic fruit collecting system

A fruit collection and power device technology, which is applied in the fields of picking machines, agricultural machinery and implements, applications, etc., can solve the problems of inability to collect, inability to ensure the integrity of easily bruised fruits, operator fatigue, etc., and achieve manpower saving and efficient fruit collection. High efficiency of work and collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

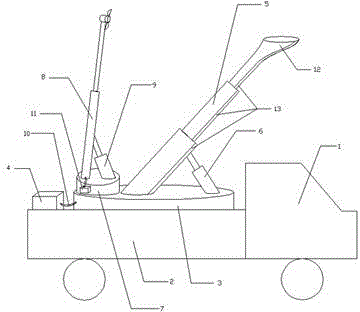

[0023] like figure 1 As shown, a kind of automatic fruit collecting system that the present invention proposes, comprises transport locomotive head 1, the storage tank 2 that tows behind transport locomotive head 1, the first rotating platform 3 that is positioned at storage tank 2 top and console 4; A telescopic hollow delivery pipe 5 and a first hydraulic lifting device 6 matched with the telescopic hollow delivery pipe 5 are installed on the platform 3; a second rotary platform 7 is also installed on the first rotary platform 3; A retractable cutting device 8 and a second hydraulic lifting device 9 matched with the retractable cutting device 8 are installed on the second rotating platform 7; the console 4 is connected with the first rotating platform 3 and the The second rotating platform 7 is connected; the telescopic hollow deli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com