Engine lubrication system

A lubrication system and engine technology, applied in the direction of engine lubrication, engine components, machines/engines, etc., can solve the problems of high pressure, long oil passage, poor lubrication effect, etc., to ensure the lubrication effect, good lubrication effect, The result is a simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

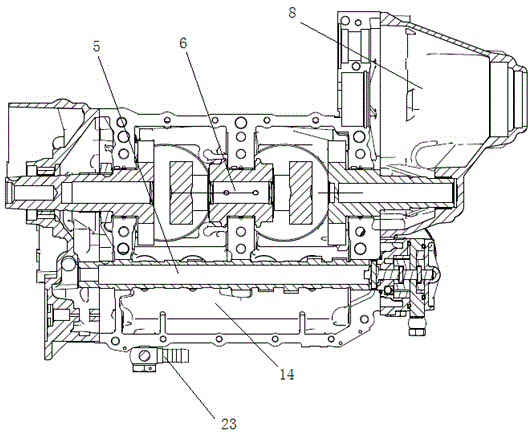

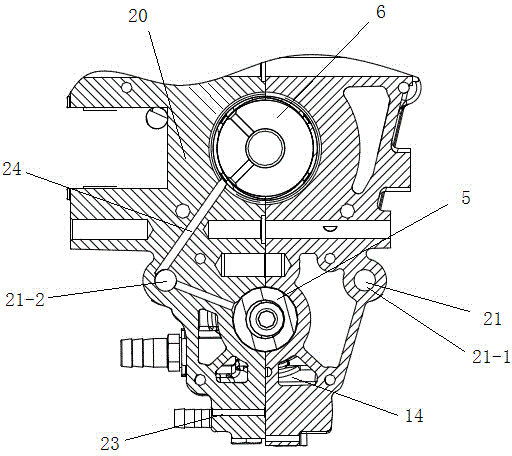

[0031] Embodiment 1, a kind of engine lubricating system, see figure 1 , figure 2 and Figure 4 , including a casing 20, the casing 20 is provided with a turbocharger 17, a lubricating oil tank 1, an oil cooler 2, an oil pump 3 and an oil filter 3-1 connected in sequence, and the oil filter 3-1 is connected with the casing The main oil passage 21 in 20 is connected; the box body 20 is provided with a crankshaft hole 6 and a camshaft hole 5, and the main oil passage 21 is connected with the crankshaft hole 6, the camshaft hole 5 and the two sides of the camshaft hole 5 for installing hydraulic jacks. The mounting hole 22 of the post communicates.

[0032] The crankshaft includes a front crankshaft, a middle crankshaft and a rear crankshaft, and the front crankshaft, the middle crankshaft and the rear crankshaft respectively include a main shaft 6-1 and a crank arm 6-6 and are connected as one by pressing the crank pin 6-2 on the main shaft 6-1. The crank pin 6-2 is rotation...

Embodiment 2

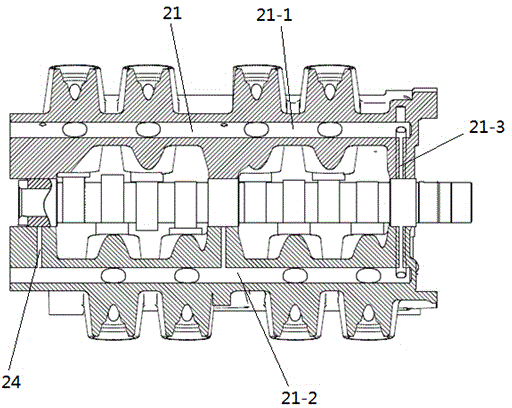

[0037] Embodiment 2, an engine lubrication system, on the basis of Embodiment 1, the main oil passage 21 includes an oil inlet section 21-1, an oil outlet section 21-2 and forms a U shape through a connecting section 21-3, the main oil passage 21 communicates with the crankshaft hole 6 and the camshaft hole 5 through the first oil hole 24; the two sides of the camshaft hole 5 are respectively provided with installation holes 22 for installing hydraulic tappets, and the installation holes 22 on one side are connected with the oil inlet section 21-1 communicated, and the mounting hole 22 on the other side communicates with the oil outlet section 21-2.

[0038] In order to achieve all-round lubrication, the oil inlet section 4-1 and the oil outlet section 4-2 are respectively provided with an oil hole 5 communicating with the crankshaft hole 2 and the camshaft hole 3 .

[0039] The hydraulic tappet 9 is connected to the rear end of the valve rocker arm 11 through a push rod 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com