Tension regulating device for embedded type spinning

A technology of tension adjustment device and yarn guide device, which is applied in the direction of textiles and papermaking, and can solve problems such as inconsistency in tension, large footprint, and production interruption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

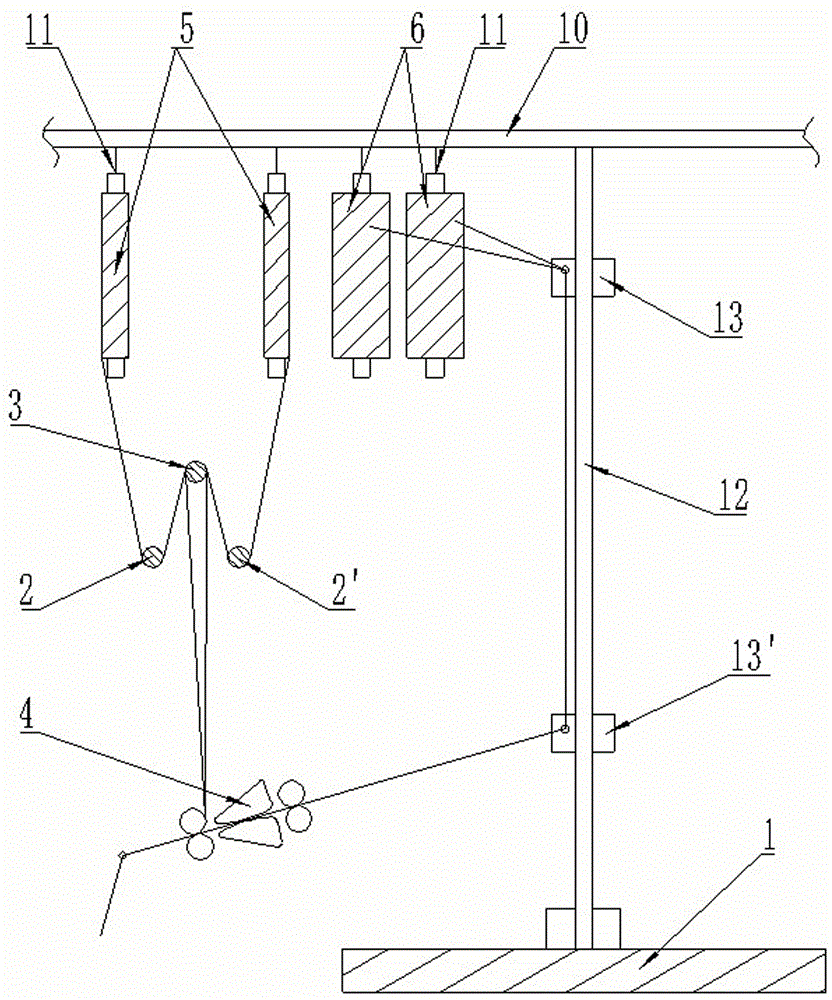

[0007] The present invention will be further described below in conjunction with the accompanying drawings.

[0008] Such as figure 1 It can be seen that the tension adjusting device for embedded spinning of the present invention includes a creel 1, four sets of spindle hanging devices 11 are arranged on the cross bar 10 of the creel 1, and the vertical bar 12 of the creel 1 There are upper and lower yarn guide devices 13, 13'; a filament tension adjustment device is provided below the spindle hanging device 11; the filament tension adjustment device includes front and rear positioning rods 2, 2 set at equal heights. ', an adjustment rod 3 is arranged above the front and rear positioning rods 2, 2', and the front and rear positioning rods 2, 2' are arranged in parallel with the adjustment rod 3; below the filament tension adjustment device A front drafting device 4 is provided.

[0009] During the work of the present invention, two groups of high-pressure filaments 5 and two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com