Three-dimensional fermentation pit sealed fermentation device and pit sealing method

A technology for sealed fermentation and cellar, which is applied in the fields of biochemical equipment and methods, wine cellar utensils, preparation of alcoholic beverages, etc., and can solve the problems of poor wine quality, insufficient fermentation of upper grain fermented grains, and miscellaneous taste of original wine. , to increase the height, improve the quality of liquor production, and ensure the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

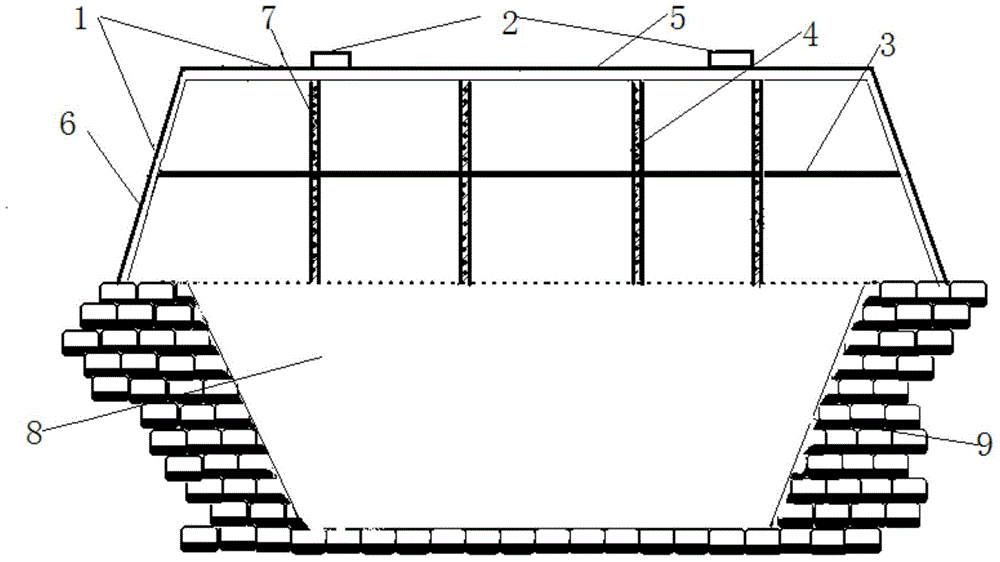

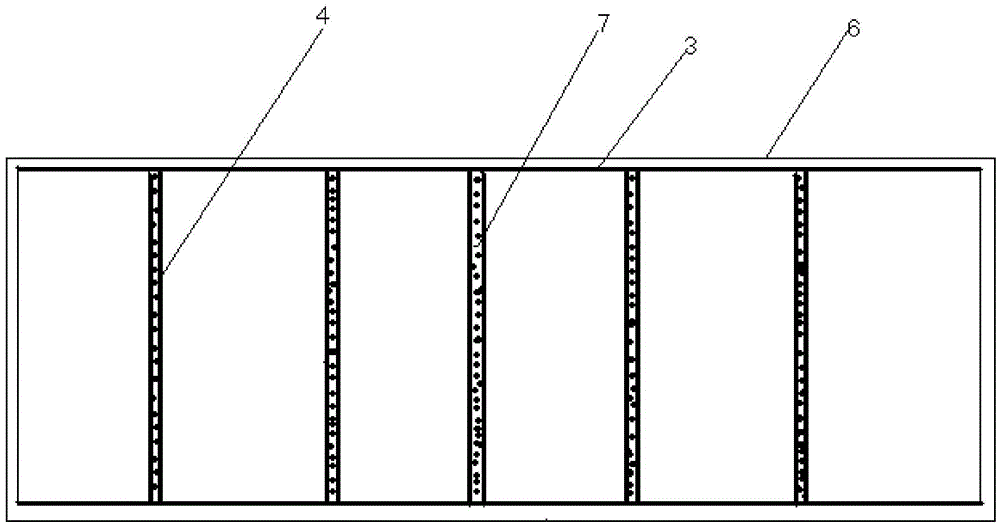

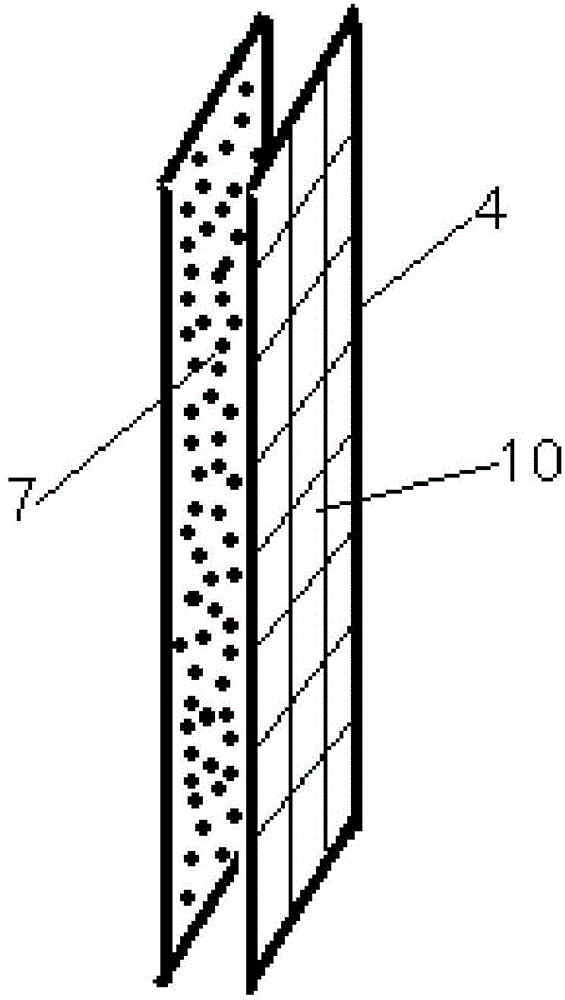

[0021] Such as figure 1 As shown, the present invention includes a cellar cover 1, and the cellar cover 1 includes a cover top 5 and a lower box body 6 with an inner cavity, and the cover top 5 is arranged on the top opening of the lower box body 6, and also includes a cellar mud plate 4, so The pit mud plate 4 is arranged in the lower box body 6, the pit mud plate 4 is hollow, the hollow part of the pit mud plate 4 is a storage space for the pit mud, and the outer wall of the pit mud plate 4 is provided with a Through-holes for storage space. The height of the cellar cover 1 is determined according to actual conditions, so as to meet different fermentation requirements. The lower casing 6 of the cellar cover 1 can increase the capacity of the distiller's grains 8 . The pit mud plate 4 can be designed into different shapes, and its main function is to make the pit mud 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com