Plastic particle easy to dry

A technology of plastic pellets and colloidal pellets, applied in fire-resistant coatings, coatings, etc., can solve the problems of easy fire, waste of energy and working hours, poor air permeability, etc., and achieve the effect of good effect and fast drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments, but the scope of implementation of the present invention is not limited thereto.

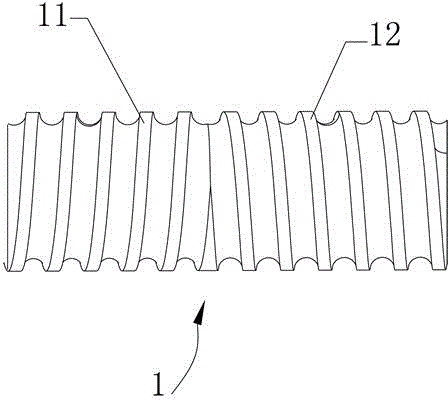

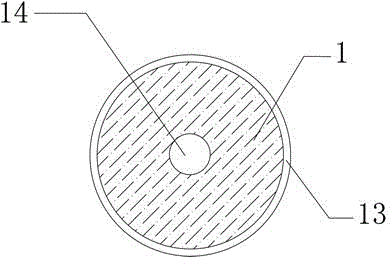

[0017] like Figure 1 to Figure 2 As shown in the figure, the easy-drying plastic pellets in this embodiment include a columnar pellet body 1; the surface of the pellet body 1 is provided with a first threaded structure 11; the two end faces of the pellet body 1 It is provided with a halogen-free and low-smoke polyolefin coating; through this thread structure, there is a gap between the rubber particles when they are stacked, which can effectively make the air circulate, dry quickly and have a good effect. In addition, since the two end faces of the rubber particles are provided with halogen-free and low-smoke polyolefin coatings, they have a certain fire resistance.

[0018] For the easy-drying plastic pellets in this embodiment, the length of the pellet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com