Harmonic-wave speed reducer with improved structure

A harmonic reducer, rigid wheel technology, applied in mechanical equipment, belts/chains/gears, transmissions, etc., can solve problems such as the difficulty of widespread use of harmonic reducers, to eliminate the possibility of failure, load capacity and The effect of enhanced impact resistance and convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

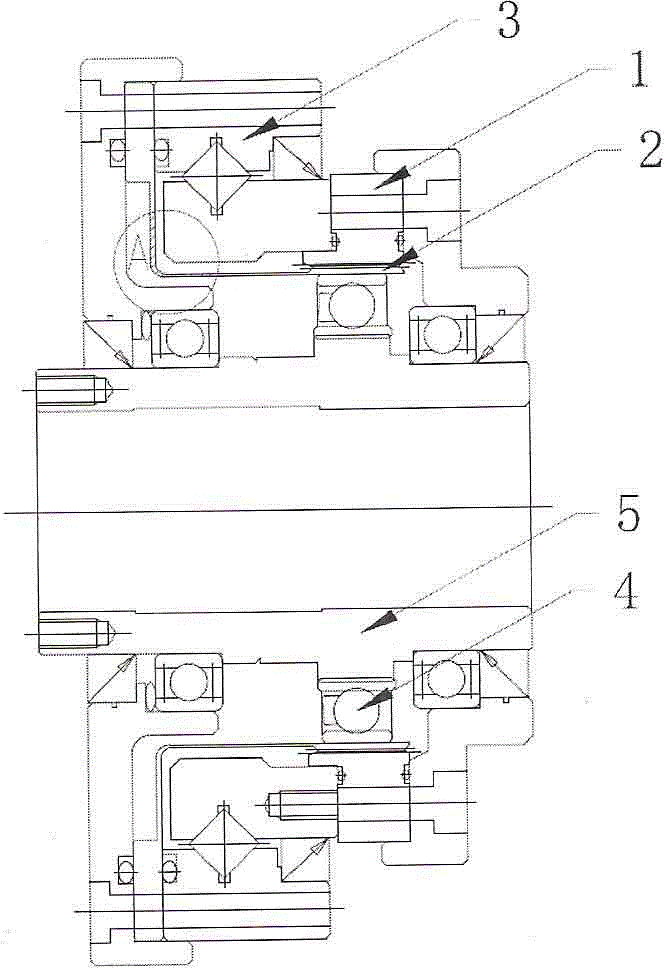

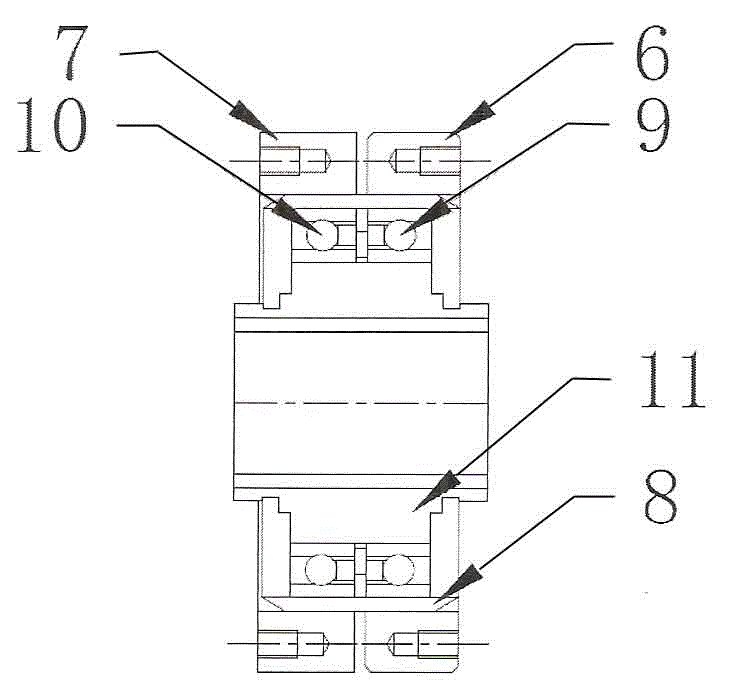

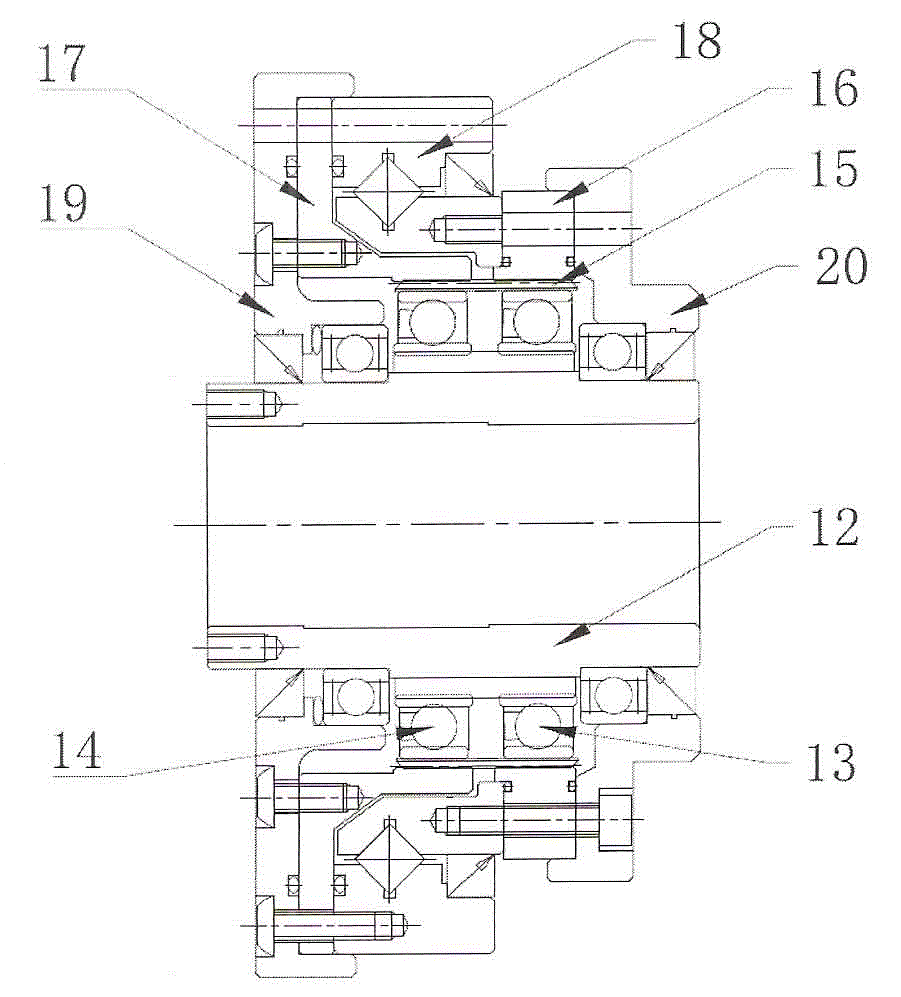

[0018] An improved structure harmonic speed reducer has a double rigid wheel structure, and the flexible wheel is in the shape of a ring. It has main components: elliptical wave generator 12, flexible bearing 13, flexible bearing 14, flexible wheel 15, rigid wheel 16, rigid wheel 17, cross roller bearing 18, front end cover 19 and rear end cover 20. Two identical flexible bearings (13, 14) are mounted on the wave generator 12. The flexible spline 15 is in the shape of a ring, is installed on the outer ring of the flexible bearing, and is bent into an ellipse. The number of internal teeth of the rigid wheel 16 is 2 more than the number of external teeth of the flexible wheel 15, and it is connected with the rear end cover 20 and the inner ring of the cross roller bearing 18 as the fixed end of the harmonic reducer. The number of internal teeth of the rigid wheel 17 is the same as the number of external teeth of the flexible wheel 15, and it is connected with the front end cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com