Abnormal concrete grouting system and grouting method

A metamorphic concrete and grouting system technology, which is applied in construction, infrastructure engineering, etc., can solve the problems of reduced precision, long-term work, wear or damage of solenoid valves, etc., to reduce labor intensity, facilitate field construction, ensure construction efficiency and quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

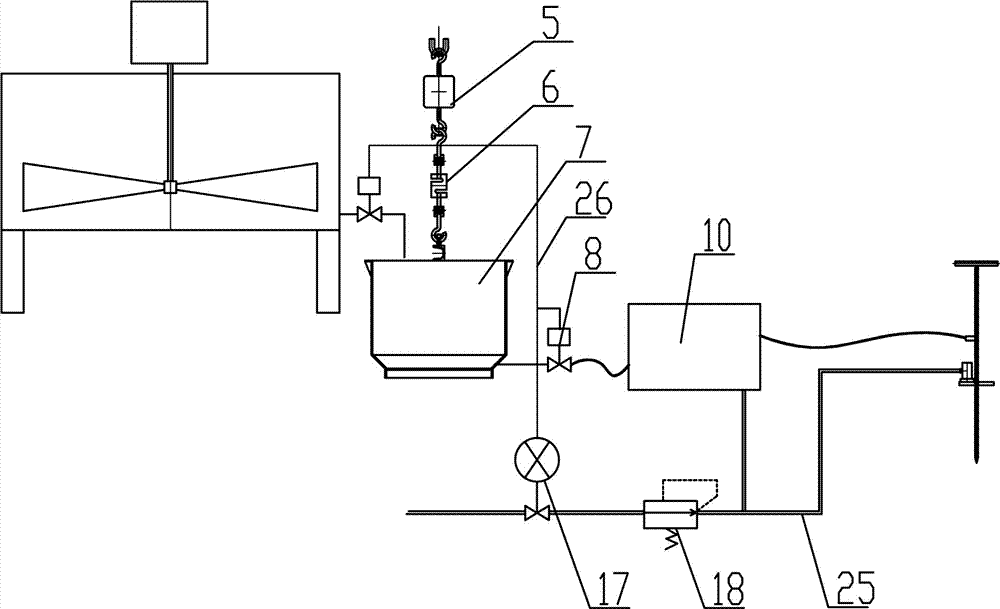

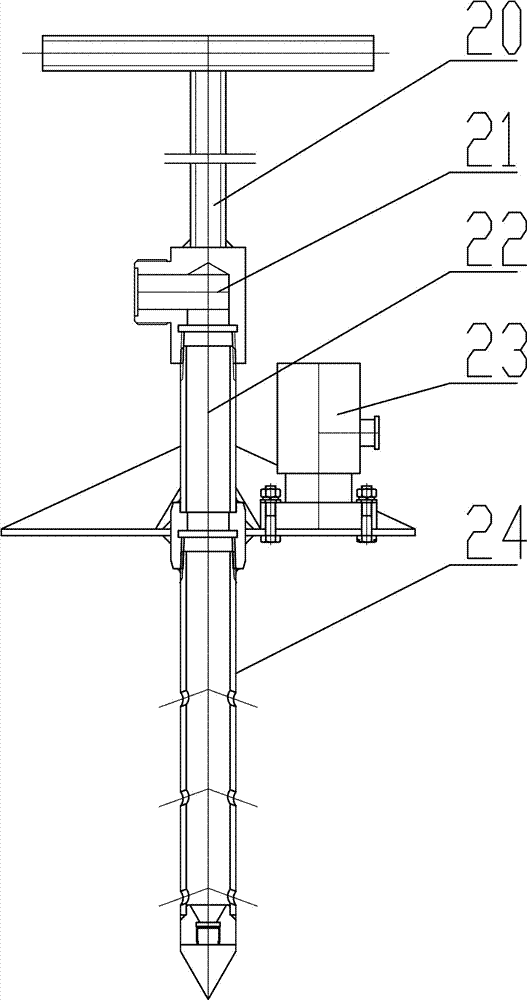

[0031] Such as figure 1 Among them, a metamorphic concrete grouting system, the measuring barrel 7 is provided with a weight sensor 6, the preferred solution is that the weight sensor 6 is a tension sensor, and the measuring barrel 7 is connected to the suspension device 5 through the tension sensor. The suspension device 5 in this example is preferably a chain block, and the advantage of using the suspension device is that only one tension sensor is needed, and the control is relatively simple. It is also possible to adopt the scheme of supporting the measuring bucket 7 on the weight sensor 6 , such measurement and control are relatively complicated, and more weight sensors 6 are required.

[0032] The agitator 3 supplies slurry to the measuring barrel 7 through the first valve 4. The first valve 4 is a manual valve, an electric valve or a pneumatic valve, and a pneumatic valve is used in this example.

[0033] The measuring barrel 7 is connected with the grouting device thr...

Embodiment 2

[0051] Different from implementation 1, an air compressor is not provided in this example, and a generator 1 is provided in this example, and the generator 1 supplies power for the agitator 3, the pump 10 and the vibrator 23;

[0052] A control device 2 is also provided, and the control device 2 is connected to the weight sensor 6 , the vibrator 23 and the pump 10 through a control circuit 26 .

[0053] A wireless receiving module 13 is also provided, and the wireless receiving module 13 is connected with the control device 2 , and the wireless receiving module 13 is also connected with the remote controller 19 in a wireless manner.

[0054] A grouting method using the above-mentioned metamorphic concrete grouting system, comprising the following steps:

[0055] 1. Open the first valve 4, the slurry stirred in the agitator 3 enters the measuring barrel 7, after the weight sensor 6 detects that the slurry weight reaches the set value, the control device 2 alarms, and the first ...

Embodiment 3

[0063] On the basis of Embodiment 1 or 2, there are multiple sets of measuring barrels 7 , pumps 10 and grouting devices, and each measuring barrel 7 is supplied with slurry by the agitator 3 .

[0064] Such as image 3 Among them, two sets are preferred in this example, which can realize two independent grouting processes at the same time and only one operator is required for each grouting operation, and the grouting process can be started and stopped with one key.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com