An airflow spreading device

An air flow and side plate technology, applied in textiles, papermaking, filament generation, etc., can solve the problems of discontinuous fiber spreading process, decreased fiber spreading quality, prone to turbulent components, etc., and achieves simple and compact structure, small volume, The effect of less air turbulence components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

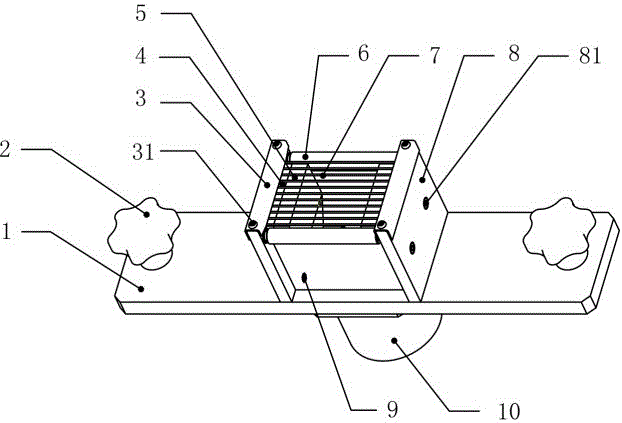

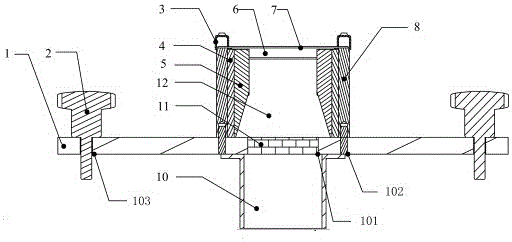

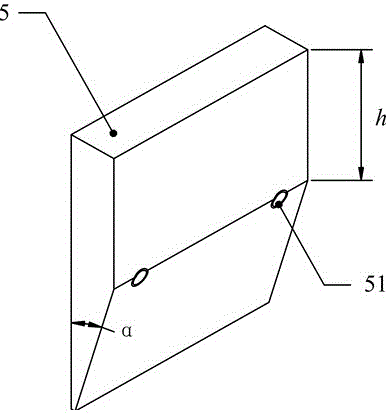

[0019] From figure 1 It can be seen from the figure that an airflow spreading device includes a base plate 1, a supporting side plate 8, a sheet metal vertical plate 9, a wedge-shaped side plate 5, a guide rod 6, a supporting rod 7, a pressure plate 3, a ventilation pipe 10 and a rectifying net 11 Wait. The central position of the base plate 1 is provided with a suction tuyere and is connected with the ventilation pipe 10. The suction tuyere has a built-in rectifying net 11. Two supporting side plates 8 are respectively fixed on the left and right sides of the suction tuyere of the base plate 1. The front and rear sheet metal vertical plates 9 are respectively clamped Insert the strip-shaped slot 82 of the supporting side plate, the base plate 1, the supporting side plate 8 and the sheet metal vertical plate 9 enclose a cavity 12; the wedge-shaped side plate 5 is symmetrically fixed on the inner side of the supporting side plate 8 by screws, forming an upper Narrow and wide u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com