Automatic alignment press-fit mechanism

A press-fit mechanism and automatic alignment technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as deviation and inaccuracy, prevent overpressure or insufficient pressure, accurate positioning, and stable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

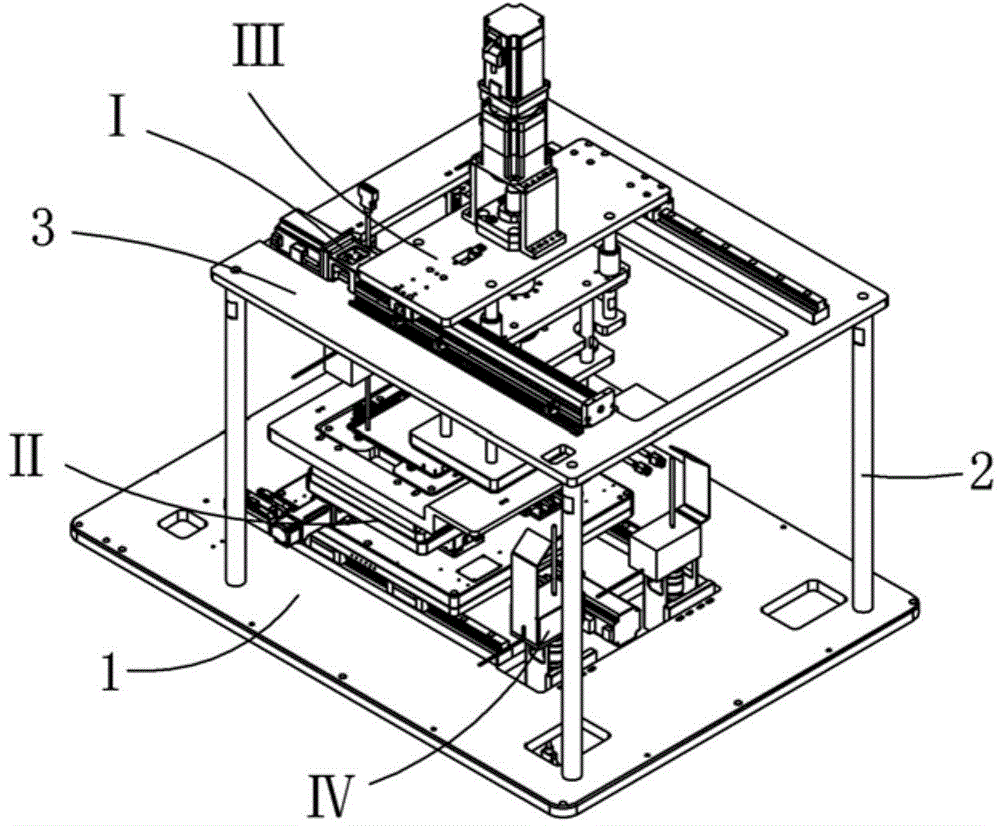

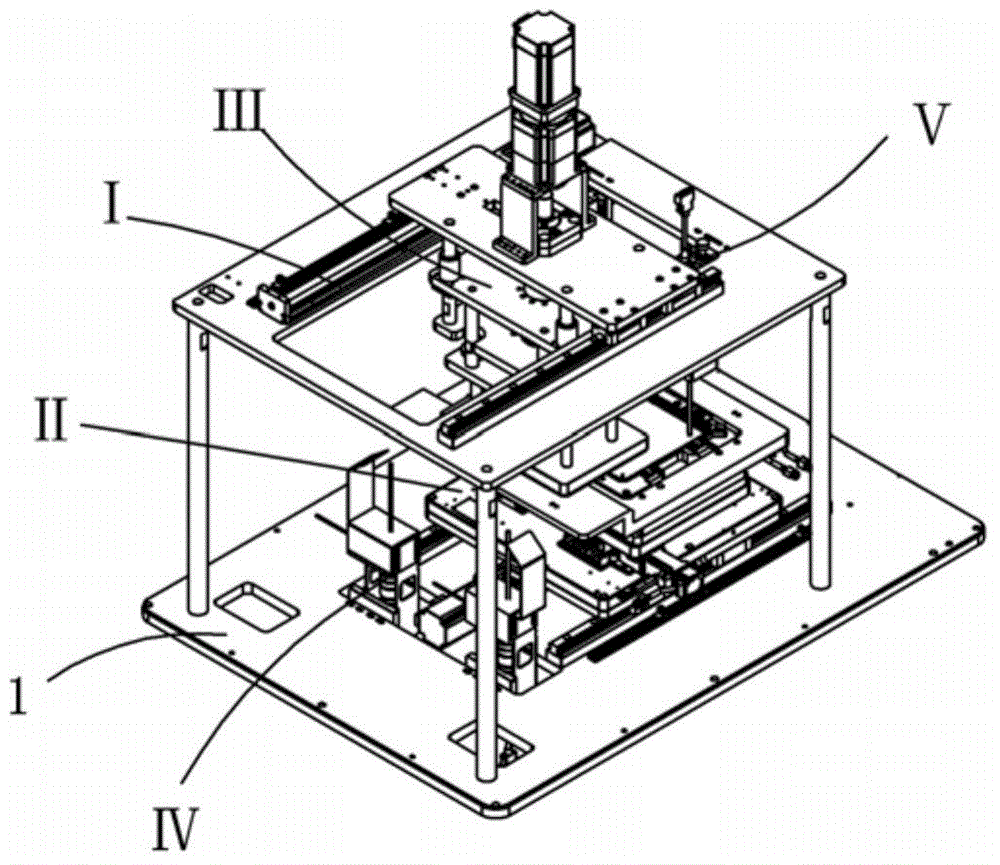

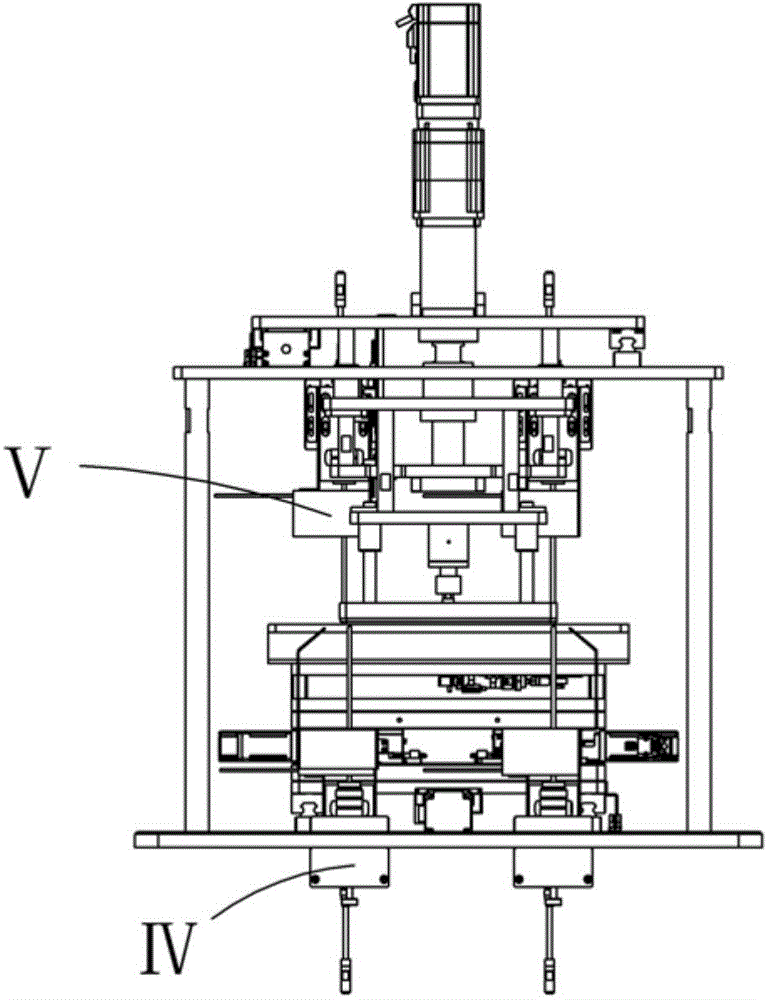

[0036] Examples, see attached Figure 1-14 , an automatic alignment and pressing mechanism, which includes a base plate 1, a support plate 3 is installed on the base plate through a support column 2, there are four support columns, and the four support columns are symmetrically installed at four corners of the support plate; A Y-axis mechanism I is installed on the support plate, and a carrier mechanism II is installed on the upper part of the bottom plate; a pressing mechanism III is installed on the Y-axis mechanism, and the pressing mechanism is located above the carrier mechanism; the Y-axis mechanism Including Y-axis motor 4, Y-axis coupling 5, Y-axis linear module 6, Y-axis linear module slider 7, pad 8, Y-axis slide rail 9 and Y-axis slider 10, the Y-axis linear The modules and pads are respectively installed on the left and right sides of the upper part of the support plate, and the pads are parallel to the Y-axis linear module; the Y-axis slide rail is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com