Tapping machining device and technology for plug of four-way reversing valve

A four-way reversing valve and processing equipment technology, applied in metal processing equipment, manufacturing tools, tangent devices, etc., can solve problems such as low production efficiency, and achieve the effects of improved production efficiency, significant reduction of personnel, and high degree of processing automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

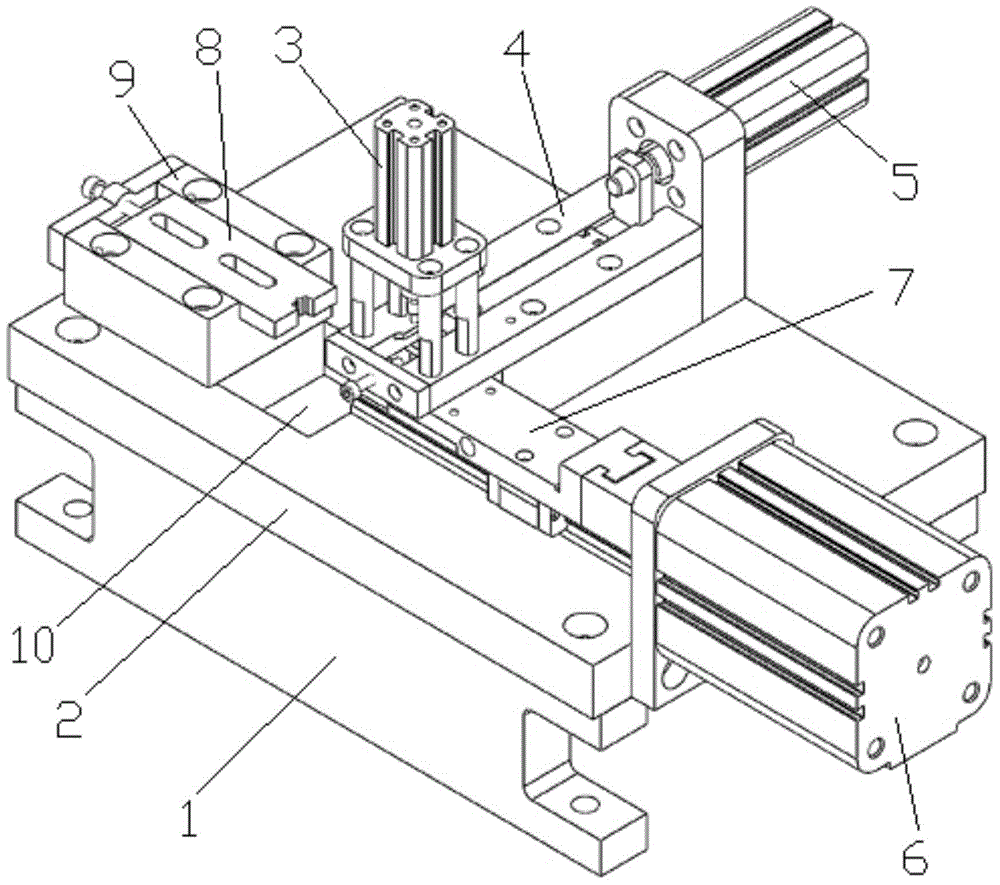

[0023] as attached figure 1 The shown four-way reversing valve head tapping processing equipment includes a bracket 1 and a bottom plate 2 installed on the bracket 1, and the bottom plate 2 is provided with a processing station for tapping a workpiece , the top of the processing station is provided with a detection cylinder 3 for detecting the workpiece, and the surroundings of the processing station are respectively provided with a feeding cylinder mechanism for loading materials, a clamping cylinder mechanism for clamping the workpiece at the processing station, and A stop mechanism that releases the workpiece from the processing station. The feeding cylinder mechanism includes a feeding channel 4 and a feeding cylinder 5 for pushing workpieces from the feeding channel 4 to a processing station. The clamping cylinder mechanism includes a clamping cylinder 6 and a slider 7 that can be pushed by the clamping cylinder 6 , and a feeding slideway can also be used to feed the sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com