High-reliability heat exchanging unit

A technology of heat exchange unit and reliability, applied in the direction of converting AC power input to DC power output, output power conversion device, electrical components, etc., can solve the problem of low working life and reliability, and high sealing performance of heat exchange unit , low power density and other issues, to achieve the effect of improving working life and working efficiency, good sealing and rainproof effect, and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

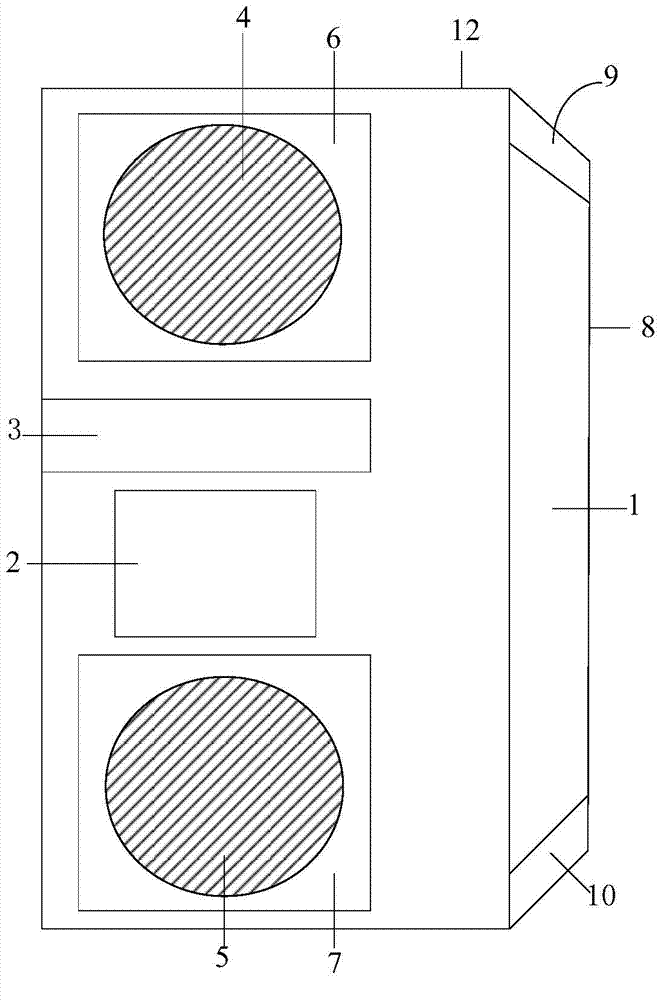

[0029] Such as figure 1 As shown, the heat exchange unit of the present invention includes a cover plate 1, a heat exchange core 2, an electric heater 3, an inner circulation fan 4 and an outer circulation fan 5, a box body 12, and also includes figure 1The controller and transformer not shown in the figure have a rectangular air outlet on the side wall of the box body 12, wherein the space surrounded by the box body 12 and the inner circulation fan 4 is called the inner circulation cavity 6, and the space surrounded by the outer circulation fan 5 is called the outer cavity. Circulation chamber 7; the inner circulation chamber 6 is located at the upper part of the heat exchange group, the outer circulation chamber 7 is located at the lower part of the heat exchange group, and the heat exchange core 2 is between the inner circulation chamber 6 and the outer circulation chamber 7. The internal circulation fan 4 is located in the internal circulation cavity 6 , and is used to suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com