Method for detecting weld seam of thin-wall small diameter tube by adopting phased array ultrasonic combination technology

A technology detection and phased array technology, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., can solve the problems of missed detection and misjudgment, difficult detection, delay of project progress, etc., and achieve the probability of missed evaluation and misjudgment Low, little influence of human factors, high quantitative accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

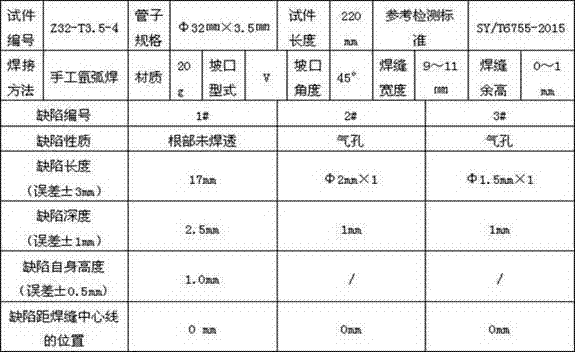

[0015] Example 1 is a simulated test piece of a pipe whose specification is Φ32mm×3.5mm. In the butt weld of the simulated test piece, there are defects of incomplete penetration of the root and pores. The butt weld parameters, defect parameters and reference testing standards of the simulated specimens are shown in Table 1.

[0016] Table 1 Z32-T3.5-4 pipe simulated defect test piece and defect design parameters

[0017]

[0018] The phased array ultrasonic combination technology is used to detect the weld seam of thin-walled small-diameter pipes with a wall thickness greater than or equal to 3.5mm and less than or equal to 7mm. On-site testing is carried out, and the test results are evaluated and the process of issuing a test report is completed.

[0019] The phased array ultrasound equipment is an ISONIC-PA-2009 phased array equipment with multiple scanning and three-dimensional image display functions.

[0020] The phased array probe is a special phased array probe f...

Embodiment 2

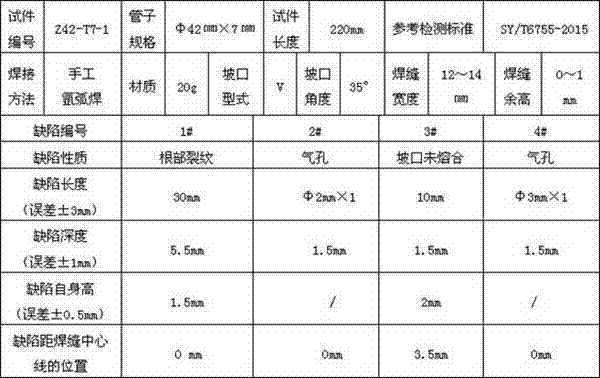

[0059] Example 2 is a pipe simulation test piece with a specification of Φ42mm×7mm, and there are cracks, unfused grooves and air hole defects in the butt weld of the simulated test piece. The butt weld parameters, defect parameters and reference testing standards of the simulated specimens are shown in Table 2.

[0060] Table 2 Z42-T7-1 pipe simulated defect test piece and defect design parameters

[0061]

[0062] The phased array ultrasonic combination technology is used to detect the weld seam of thin-walled small-diameter pipes with a wall thickness greater than or equal to 3.5mm and less than or equal to 7mm. On-site testing is carried out, and the test results are evaluated and the process of issuing a test report is completed.

[0063] The phased array ultrasound equipment is an ISONIC-PA-2009 phased array equipment with multiple scanning and three-dimensional image display functions.

[0064] The phased array probe is a special phased array probe for small-diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com