Installing structure of device cabin bottom plate

An installation structure and equipment cabin technology, applied in the field of rail vehicles, can solve the problems of inconvenient maintenance, large maintenance workload, inconvenient installation of the bottom plate 12, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The core of the present invention is to provide an installation structure for the bottom plate of the equipment cabin, which is convenient for the installation of the bottom plate and can reduce the maintenance workload.

[0035] The equipment cabin of the rail vehicle is arranged under the vehicle body, and the equipment cabin skeleton, skirt plate and floor together form a closed space for setting the equipment, pipelines and lines under the vehicle.

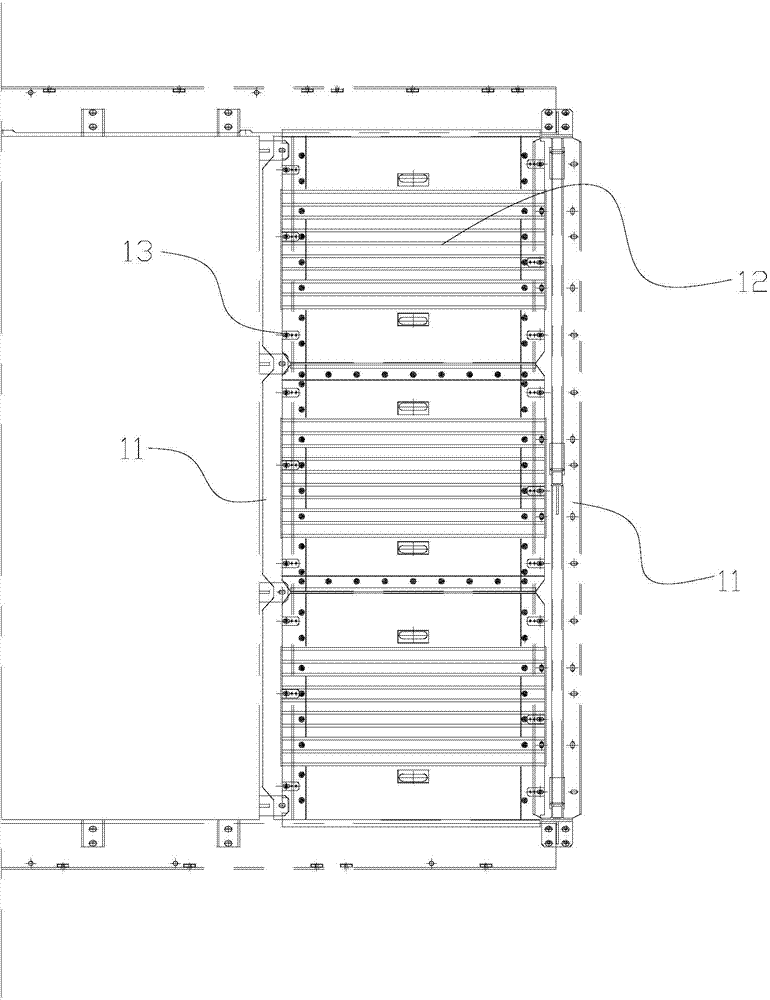

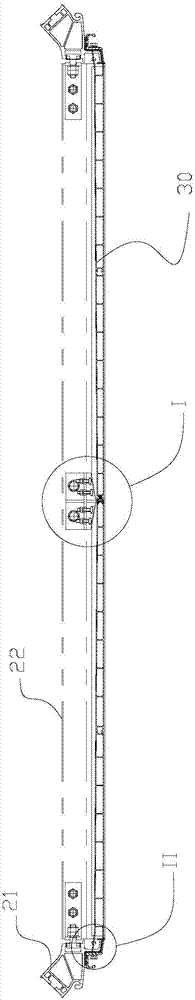

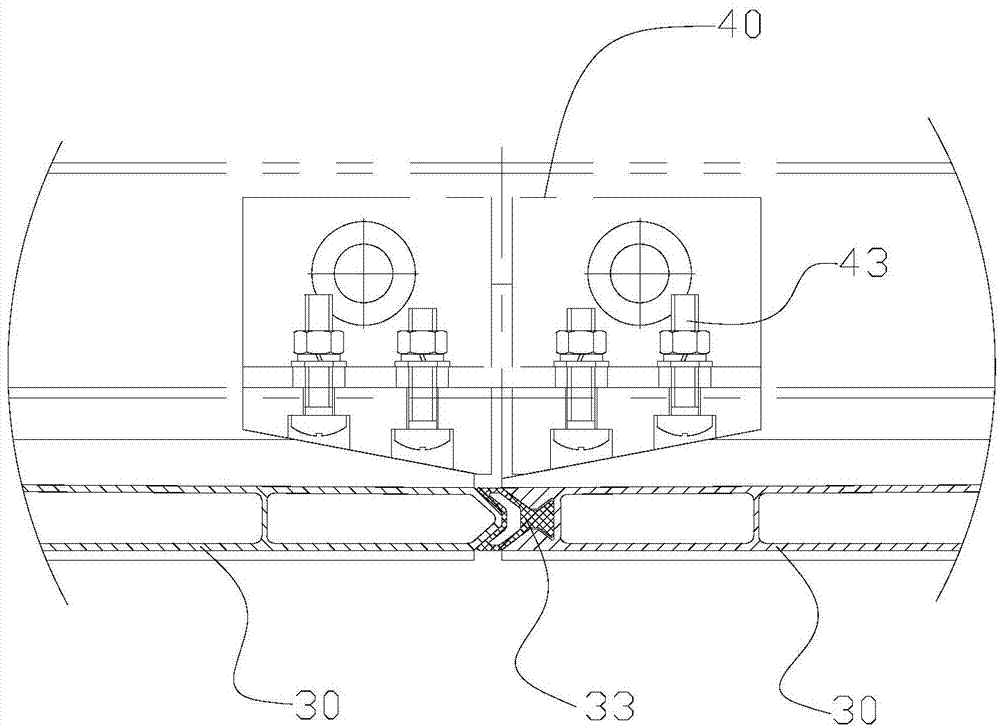

[0036] Among them, the frame of the equipment cabin includes frame side beams and frame beams, and the bottom plate is connected with the frame of the equipment cabin to seal the bottom of the equipment cabin and protect the off-vehicle equipment and pipelines in the equipment cabin from damage during vehicle operation. Stone hit, freezing and other damage.

[0037] The installation structure of the bottom plate of the equipment compartment will be introduced in detail below. In order to enable those skilled in the art ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com