Device and method for checking installation wrench

A technology for checking installation and wrench, applied in the direction of measuring devices, instruments, force/torque/work measurement instrument calibration/test, etc., can solve the problems of inaccuracy, time-consuming, expensive, and cost-effective, and achieves maintenance-free and low-cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

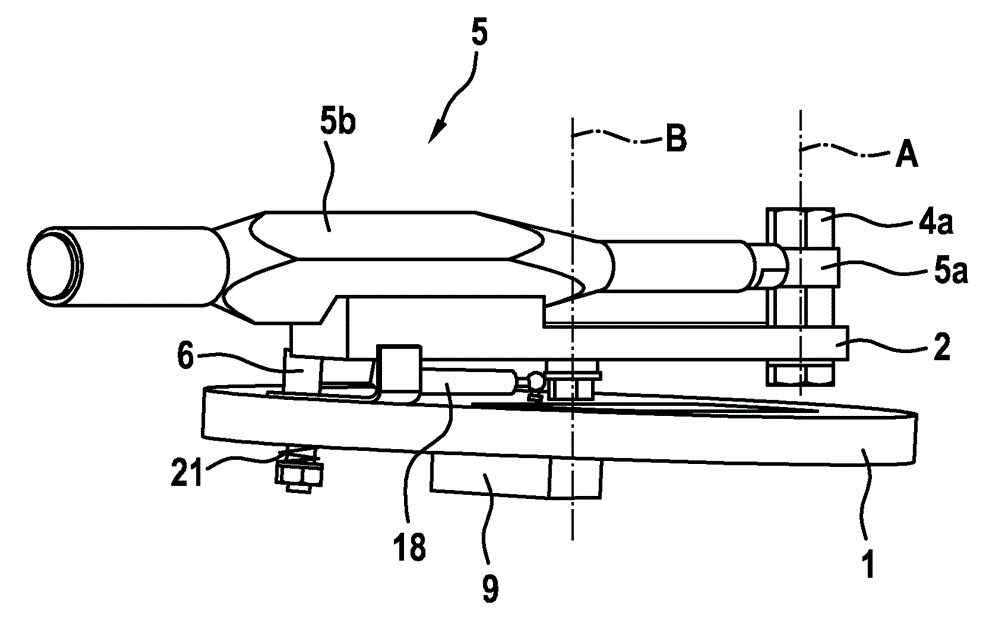

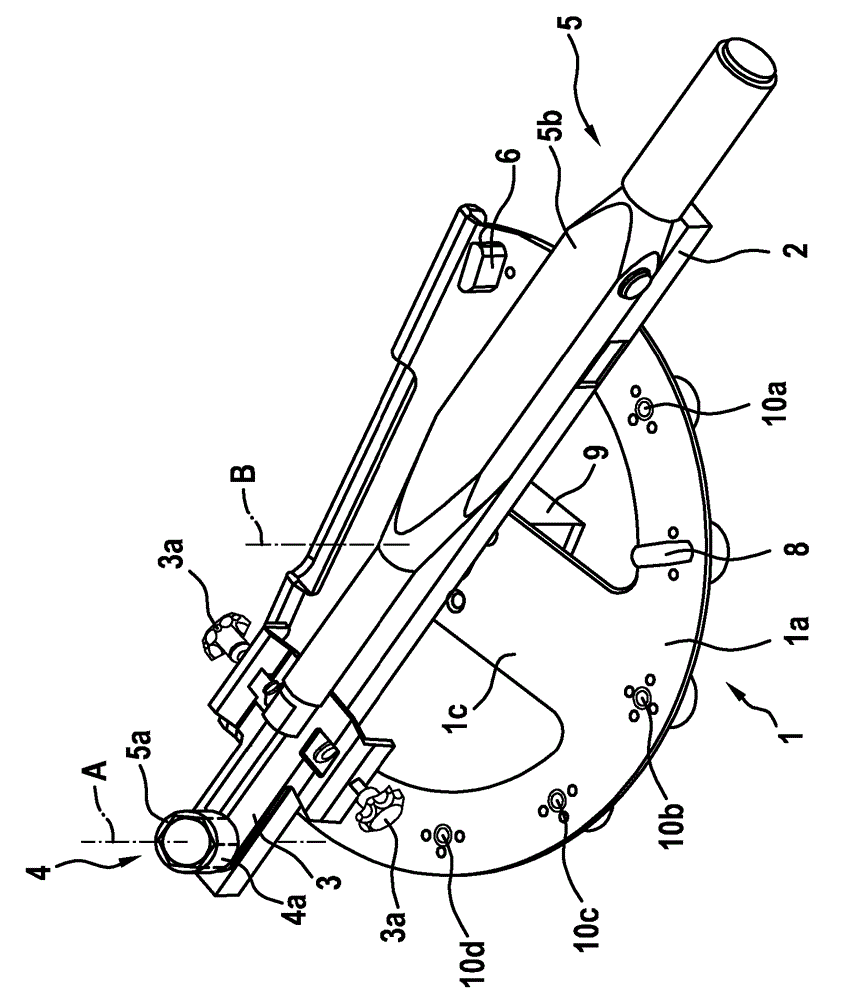

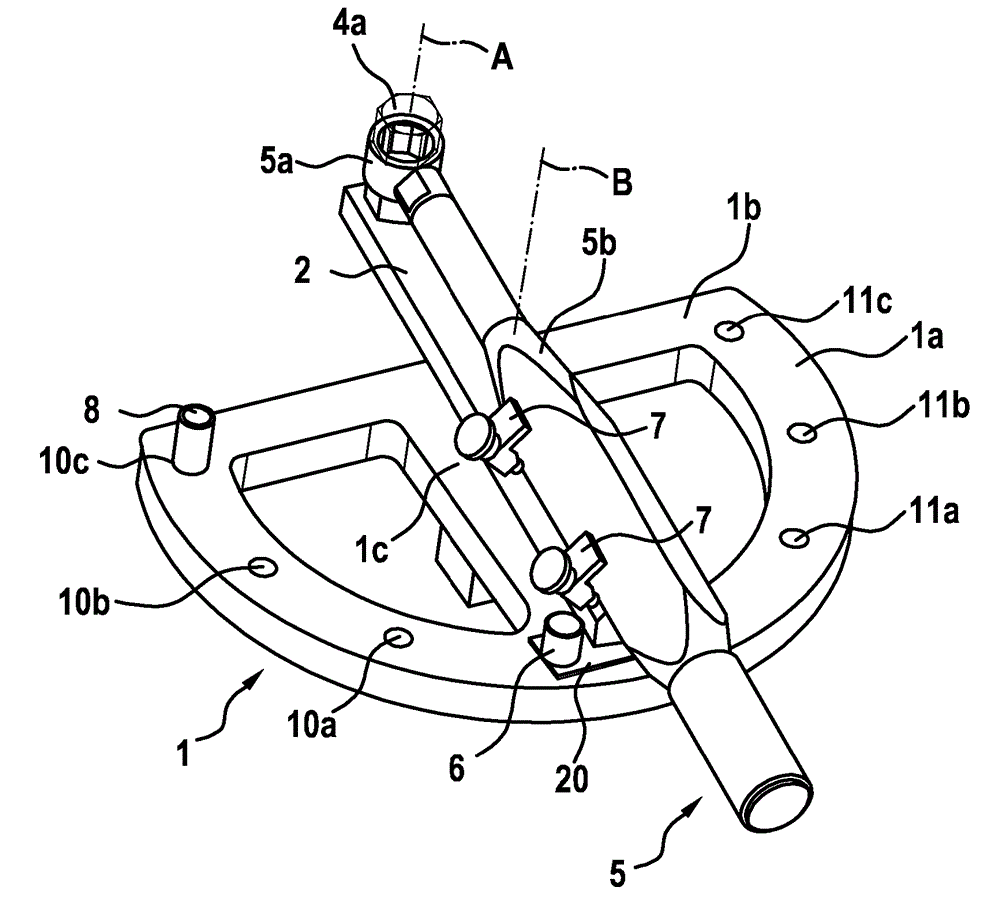

[0027] Figures 1a to 1c In stereo view ( Figure 1a ), side view ( Figure 1b ) and top view ( Figure 1c ) shows a first embodiment of the inspection device according to the invention.

[0028] The inspection device has a base plate 1 which is configured with a semicircular region 1a and a first straight region 1b which connects the two ends of the semicircular region 1a to one another. The second straight area 1c is configured at right angles to the first straight area 1b such that it connects the middle area of the first straight area 1b with the apex of the semicircular area 1a.

[0029] On the underside of the base plate 1 there is provided a holding block 9 on which the testing device can be clamped, for example, in a vice (not shown in the figure) and can be fixed in this way.

[0030] On the upper side of the base plate 1 opposite the bottom side, a cantilever 2 is supported such that it can surround an axis B arranged in the second rectilinear region 1c at the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com