Ultrahigh stack thickness slot wedge paper forming machine

A technology of slot wedge paper and forming machine, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of increasing the difficulty of manufacturing push rods, lengthening the length of the frame, and difficult to guarantee the forming effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

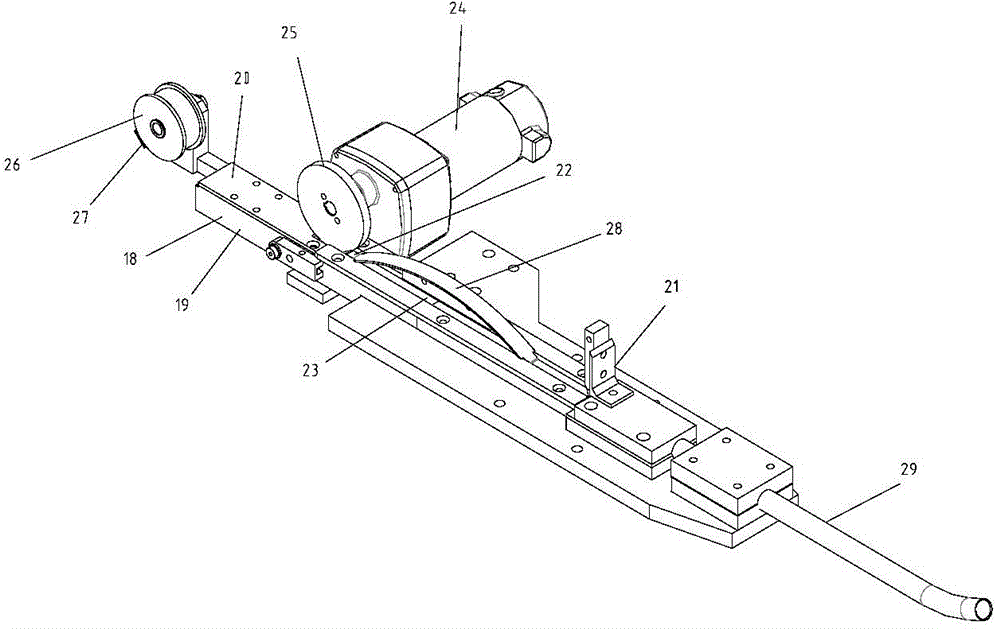

[0026] Ultra-high stacked thick groove wedge paper forming machine, including bottom plate 1, table top 2 and support column 3, the top of support column 3 is connected to the bottom of table top 2, the bottom of support column 3 is connected to the top of bottom plate 1, and support column 3 is two left and right support columns 3. The support column 3 is connected with the table top 2 and the bottom plate 1 through threads, and also includes a pre-feeding device, a pre-forming device, a forming device, a paper pushing device, a push rod 4, a material warehouse 5 and a paper cutting device, and the pre-feeding device is set On the side of the support column 3 and connected with the support column 3, a mounting plate 6 is provided between the bottom plate 1 and the table top 2, the mounting plate 6 is installed on the large plate 7, and the pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com