Power device temperature detection system

A technology of electric equipment and detection system, applied in the field of electric equipment temperature detection system, can solve the problems of reducing equipment service life, power failure experiment, equipment destructiveness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

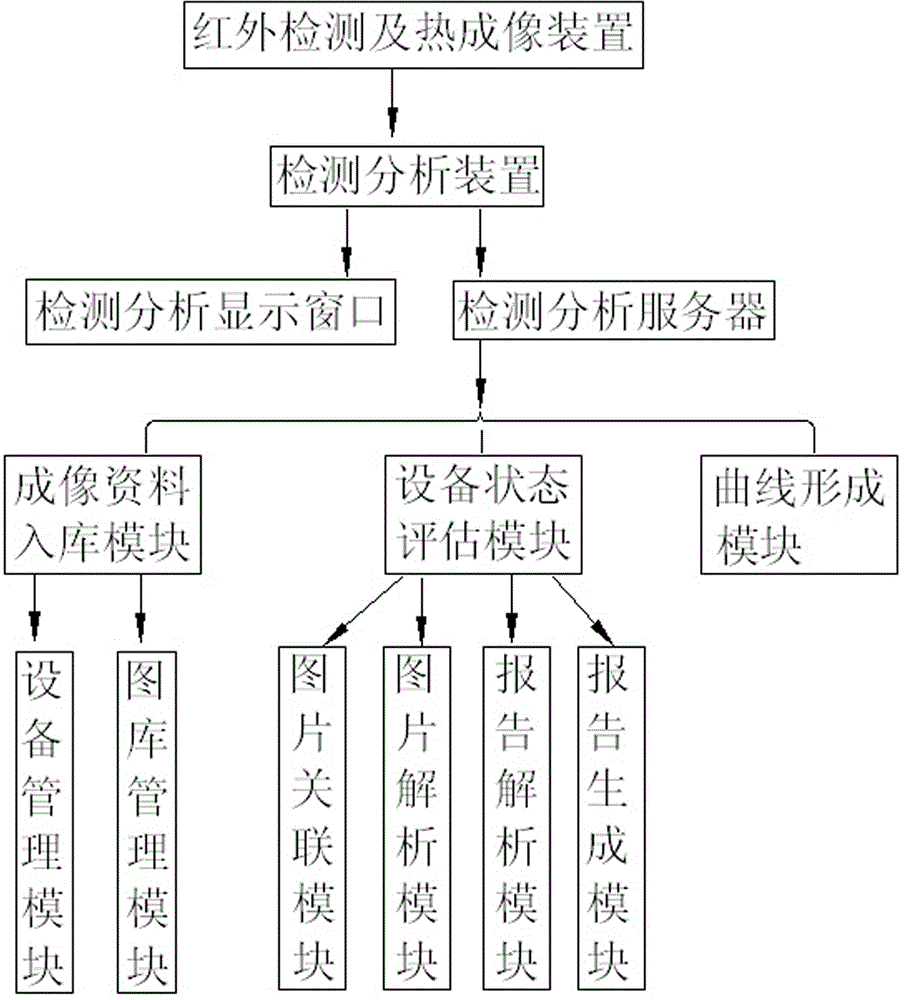

[0010] Embodiment: power equipment temperature detection system, such as figure 1 As shown, it includes an infrared detection and thermal imaging device installed on each electrical equipment, a detection and analysis device that receives information from the infrared detection and thermal imaging device, and a detection and analysis display window and a detection and analysis server are set on the detection and analysis device.

[0011] The detection and analysis server is provided with an imaging data storage module, a curve forming module and an equipment status evaluation module, and its working steps are: a. The information of infrared detection and thermal imaging devices is stored in The detection and analysis server; b. The curve forming module forms a graph of infrared detection and thermal imaging information, and displays it in the detection and analysis display window; or, the equipment status evaluation module receives the imaging data in the storage module The re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com